Preparation method of irradiation and chemistry co-modified starch

A technology of compound modified starch and modified starch, which is applied in the field of modified starch, can solve the problems of gelatinization temperature lowering below 45°C, limited reduction of starch gelatinization temperature, singleness, etc., and achieve high reaction efficiency, good stability, and guaranteed viscosity and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

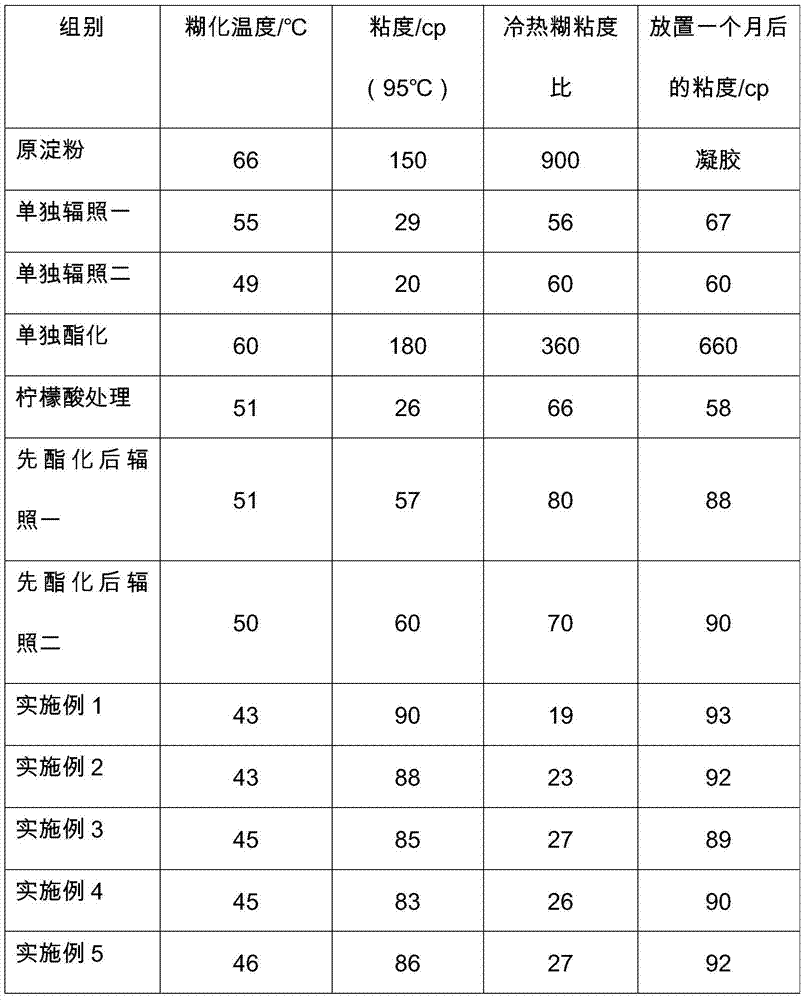

Examples

Embodiment 1

[0026] use 60 co γ - Radiation treatment of cassava starch, wherein the irradiation dose is 2KGY, the irradiation time is 1h, and the irradiation temperature is 38°C.

[0027] Disperse 500g of irradiated tapioca starch in 650mL of water (containing 5g of sodium carbonate), add 20g of vinyl acetate while stirring at 38°C, keep at 38°C for 1 hour, neutralize the pH value to 6.0 with dilute hydrochloric acid, filter, Washing and drying to get the finished product.

Embodiment 2

[0029] use 60 co γ - Radiation treatment of cassava starch, wherein the irradiation dose is 4KGY, the irradiation time is 1.5h, and the irradiation temperature is 40°C.

[0030] Take 500g of irradiated tapioca starch and disperse it in 550mL of water, add 10g of sodium hydroxide and sodium carbonate mixture as a catalyst, add 10g of vinyl acetate while stirring at 40°C, keep the reaction at 40°C for 1 hour, and neutralize the pH value with dilute sulfuric acid To 6.5, filter, wash, and dry to get the finished product.

Embodiment 3

[0032] use 60 co γ - Radiation treatment of cassava starch, wherein the irradiation dose is 2.2KGY, the irradiation time is 2.5h, and the irradiation temperature is 45°C.

[0033] Take 500g of irradiated tapioca starch and disperse it in 750mL of water (containing 25g of potassium hydroxide and sodium carbonate mixture), add 75g of vinyl acetate while stirring at 40°C, keep it at 40°C for 1.5h, and neutralize the pH value with dilute hydrochloric acid To 6.7, filter, wash, and dry to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com