Automatic plane screen paste printing technology for metalizing ceramic discharge tube

A ceramic discharge tube and metallization technology, applied in screen printing machines, printing, printing machines, etc., can solve the problems of low efficiency of manual screen printing paste, grooves on the surface of printing paste, large thickness deviation of paste layer, etc. Achieve the effect of improving the rate of high-quality products, fewer operators, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] 1. Ointment preparation: Prepare the prepared metallized molybdenum-manganese paste powder, ethyl cellulose solution, and terpineol in a certain proportion to make an ointment, and adjust the viscosity of the ointment at 5-10Pa·s.

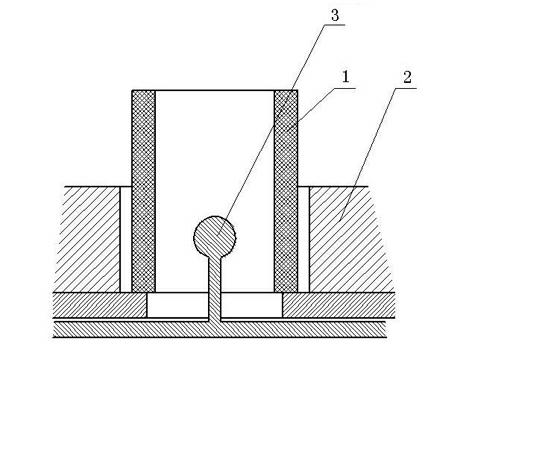

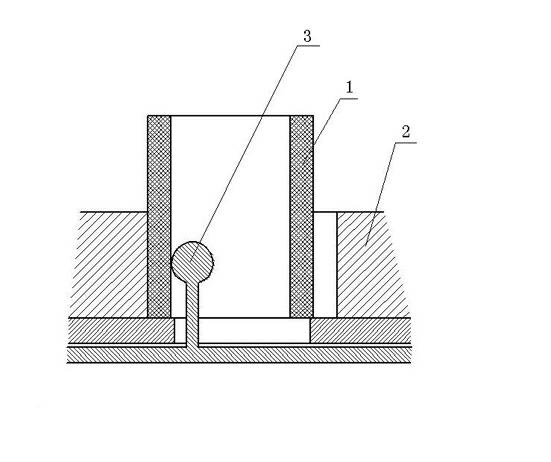

[0038] 2. If figure 1 , figure 2 As shown, a special eccentric fixture is used to fix the porcelain piece 1, which can be used without drying.

[0039] 3. Install the special stainless steel sieve 8 on the automatic flat screen printing machine. The mesh of the stainless steel sieve 8 is 100 mesh, the tension is about 300±20N / ㎝2, and the room temperature environment.

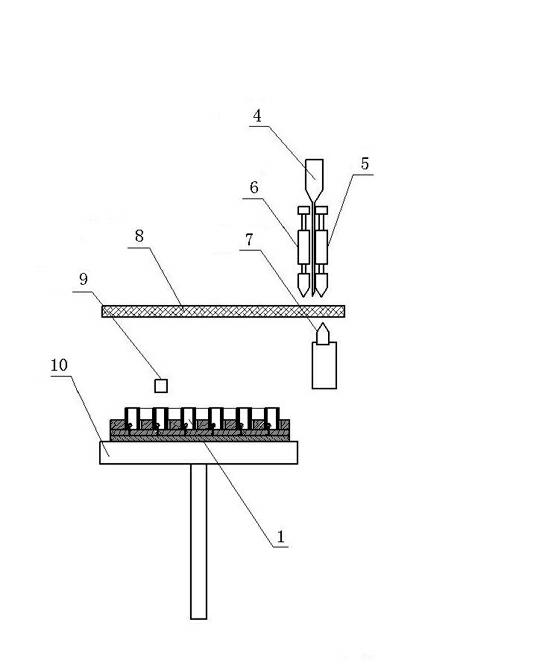

[0040] 4. If image 3 , Figure 4 As shown, adjust the squeegee 6 of the automatic flat screen printing machine, and the squeegee 6 is pressed on the porcelain piece 1 and all parts are evenly stressed; the stage 10 is adjusted to raise the distance between the porcelain piece 1 and the stainless steel screen 8 wire mesh Appropriate; adjust the slurry leakage knife 7 so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com