Epoxide-based composition

An epoxide, polyepoxide technology, applied in the direction of epoxy glue, adhesive type, adhesive, etc., can solve the odor, can not provide working time, can not apply multi-layer and non-transparent film / composite material and other problems, to achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

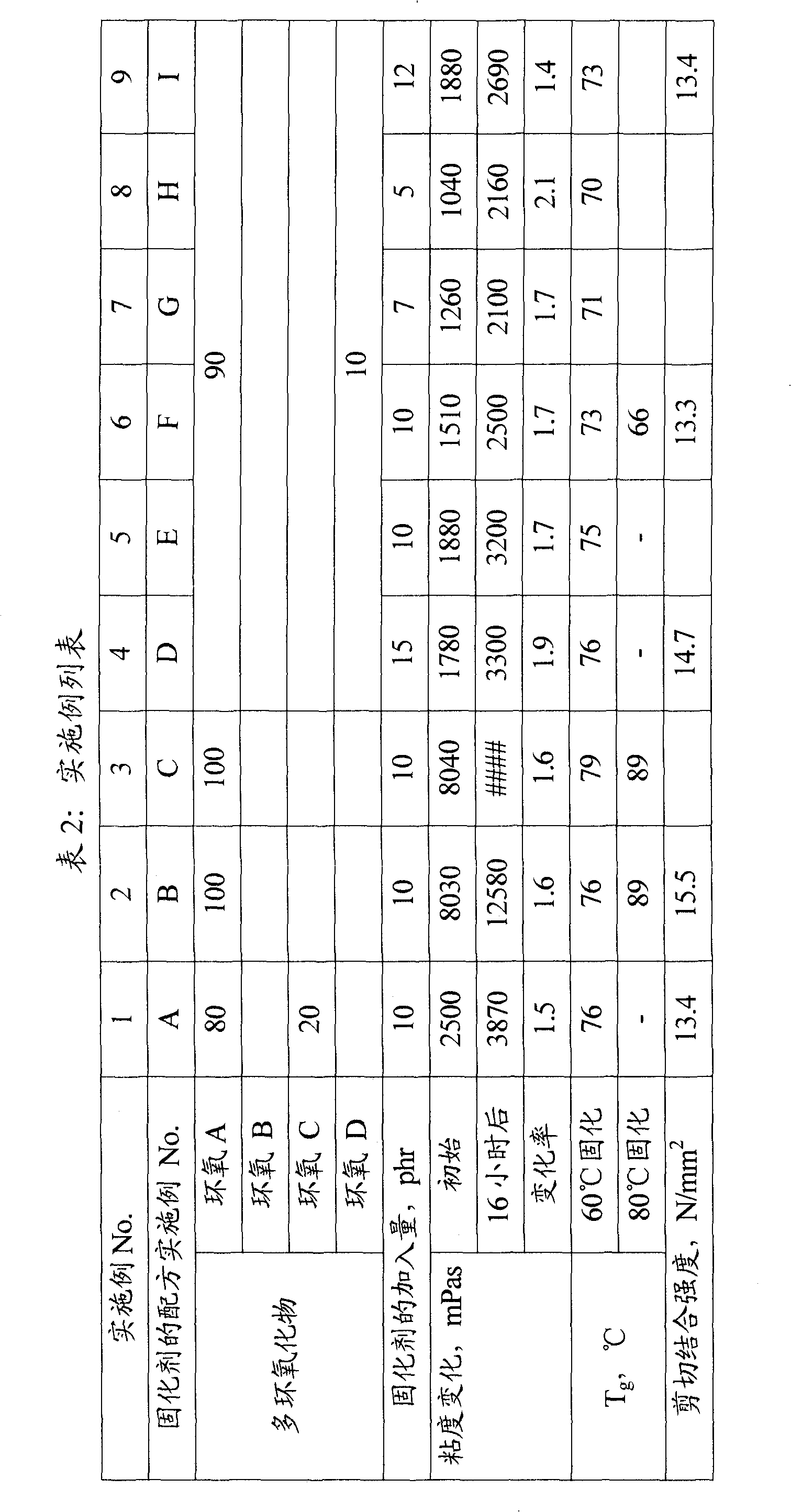

[0074]Epikote 828 Epoxy Resin (16g), Epodil 757 Epoxy Resin (4g) and Curing Agent Formulation Example A (2g) were weighed in a paper cup as shown in Table 2 and mixed thoroughly. The initial viscosity of the mixture was tested and the viscosity after 16 hours was also measured. In addition, samples for DSC testing were prepared from said samples immediately after mixing as described above, and at the same time, samples for shear binding testing were produced. The results are shown in Table 2.

Embodiment 2-18

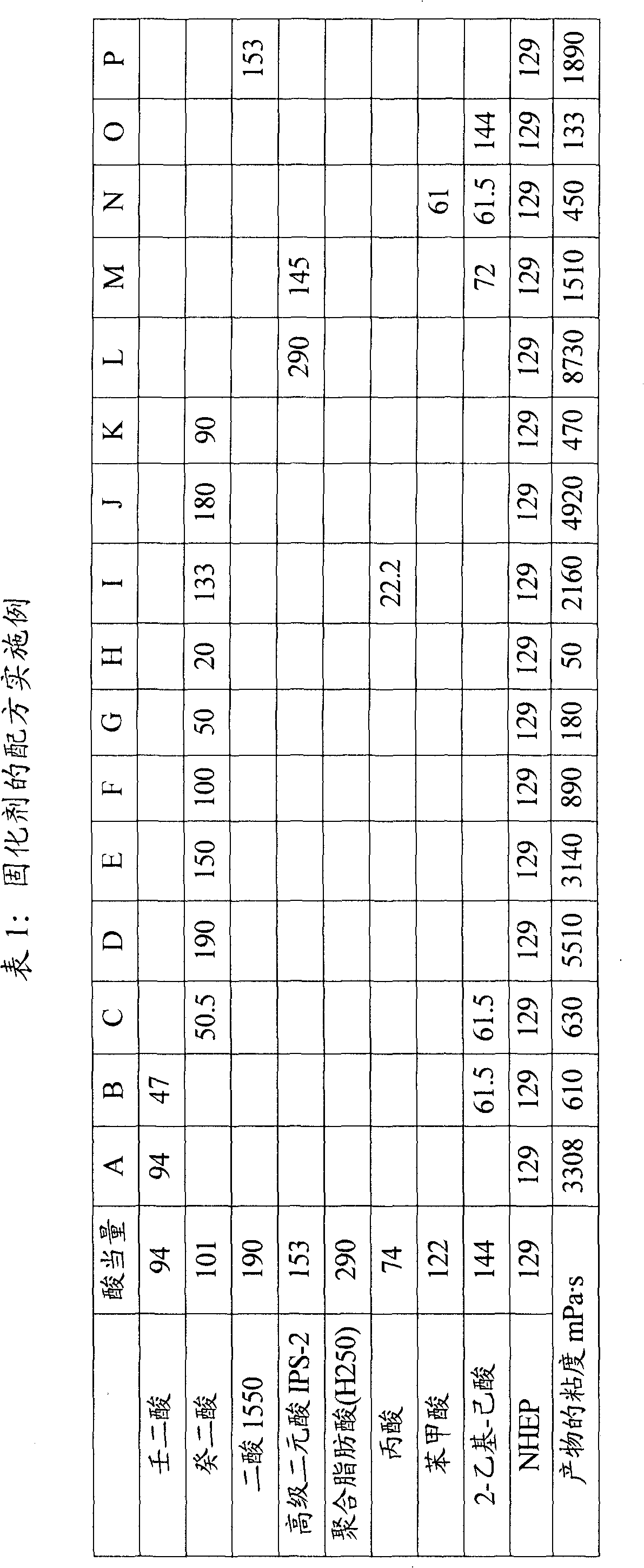

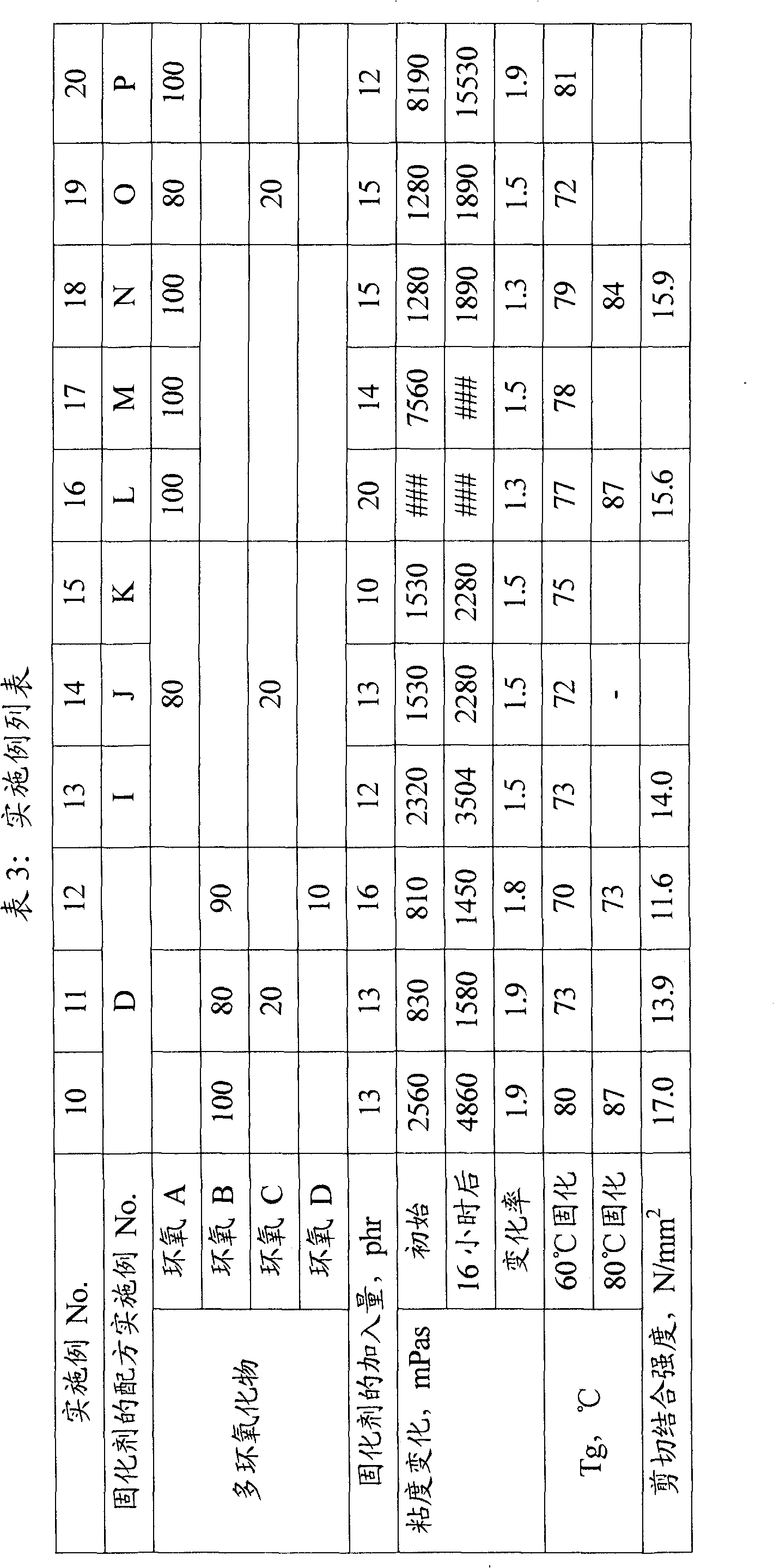

[0076] A curing agent was synthesized by changing the epoxy resin and raw materials and the ratio between them, and the same test as in Example 1 was carried out on the curing agent. The results are shown in Tables 2 and 3.

[0077]

[0078]

[0079] In the following, comparative examples are carried out on epoxy-based compositions for repairing underground pipes described in the prior art, the results of which clearly demonstrate the superiority of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com