Glue spreading device

A glue coating device and cover technology, which is applied to the device and coating of the surface coating liquid, can solve the problem of easy falling off of photo-induced anti-corrosion agent, achieve the effect of simple and ingenious structure, ensure uniformity, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

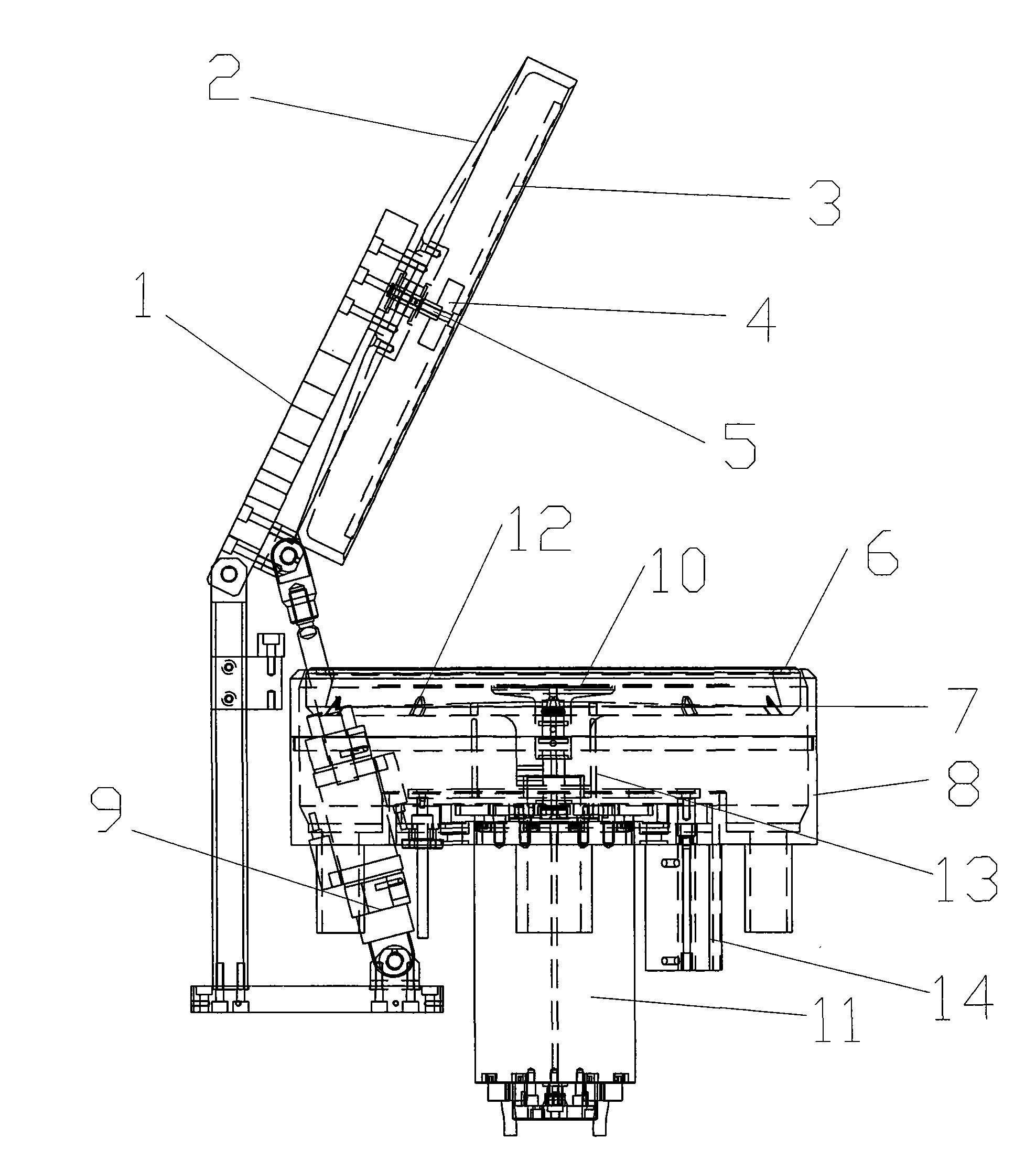

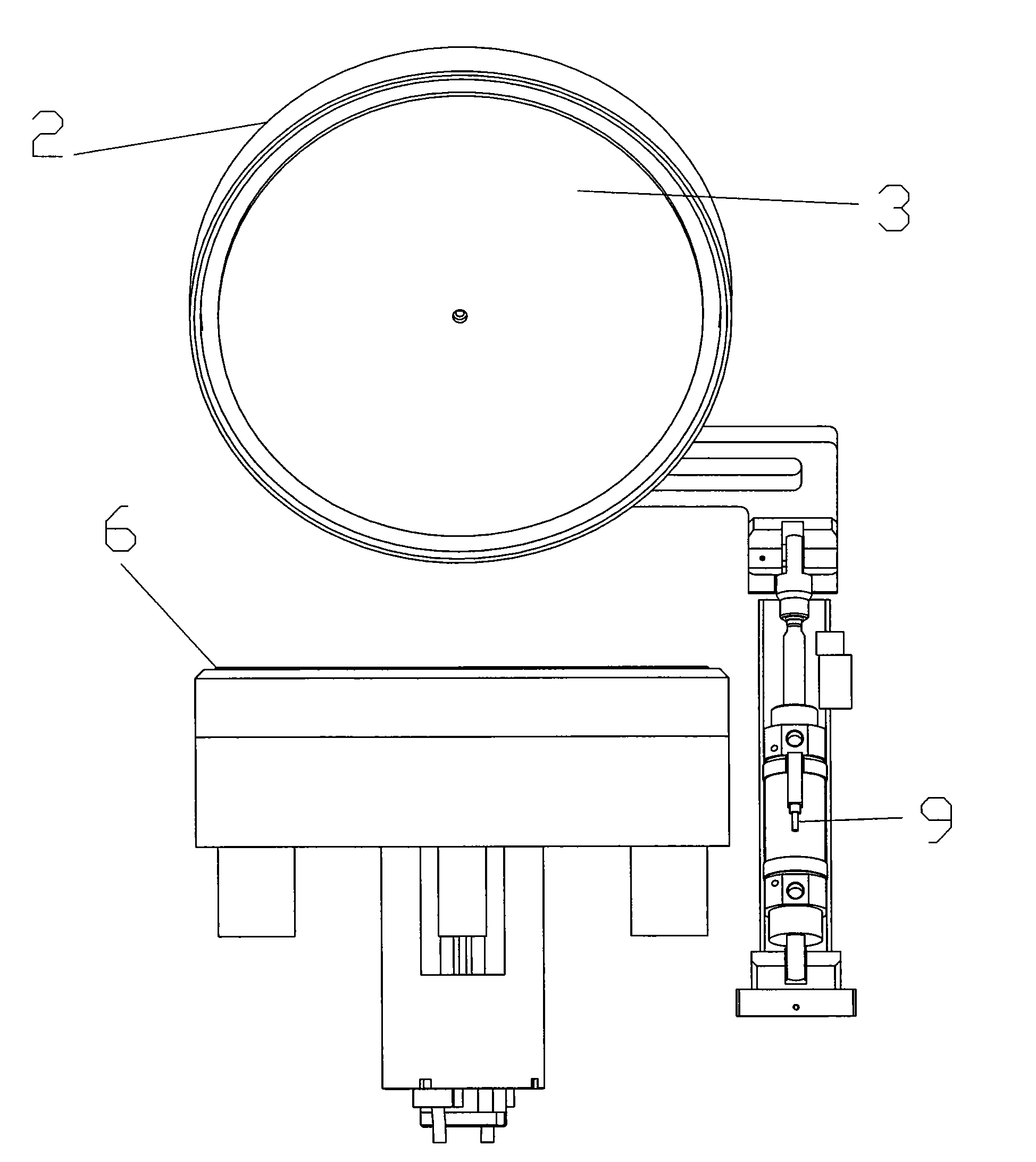

[0017] like Figure 1-Figure 2 As shown, the gluing device of the present invention is provided with a cover drive rod 1, an external cover 2, an internal sealing rotary cover 3, a rotary bearing 4, a coupling shaft 5, a sealing ring 6, a rotary cavity 7, and an external collection cup for exhaust and liquid collection. 8. Open and close cover driving cylinder 9, wafer chuck 10, rotating motor 11, colloid discharge port 12, loading wafer bracket 13, wafer bracket driving cylinder 14. The outer cover 2 and the inner sealing rotating cover 3 are connected through the coupling shaft 5 to form the upper cover of the glue application device. The outer cover 2 is located on the outside, the inner sealing rotating cover 3 is located on the inner side, and the connecting shaft 5 and the inner sealing rotating cover 3 are matched through the rotating bearing 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com