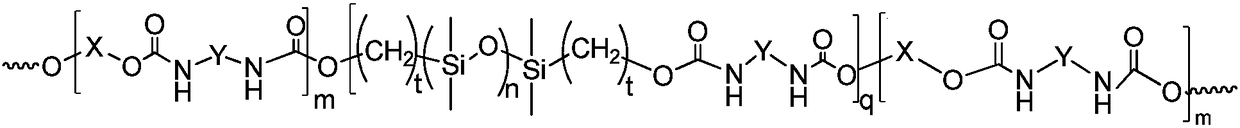

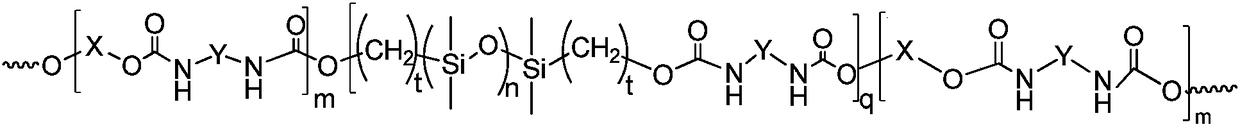

Organosilicone modification polyurethane elastomer and preparation method thereof

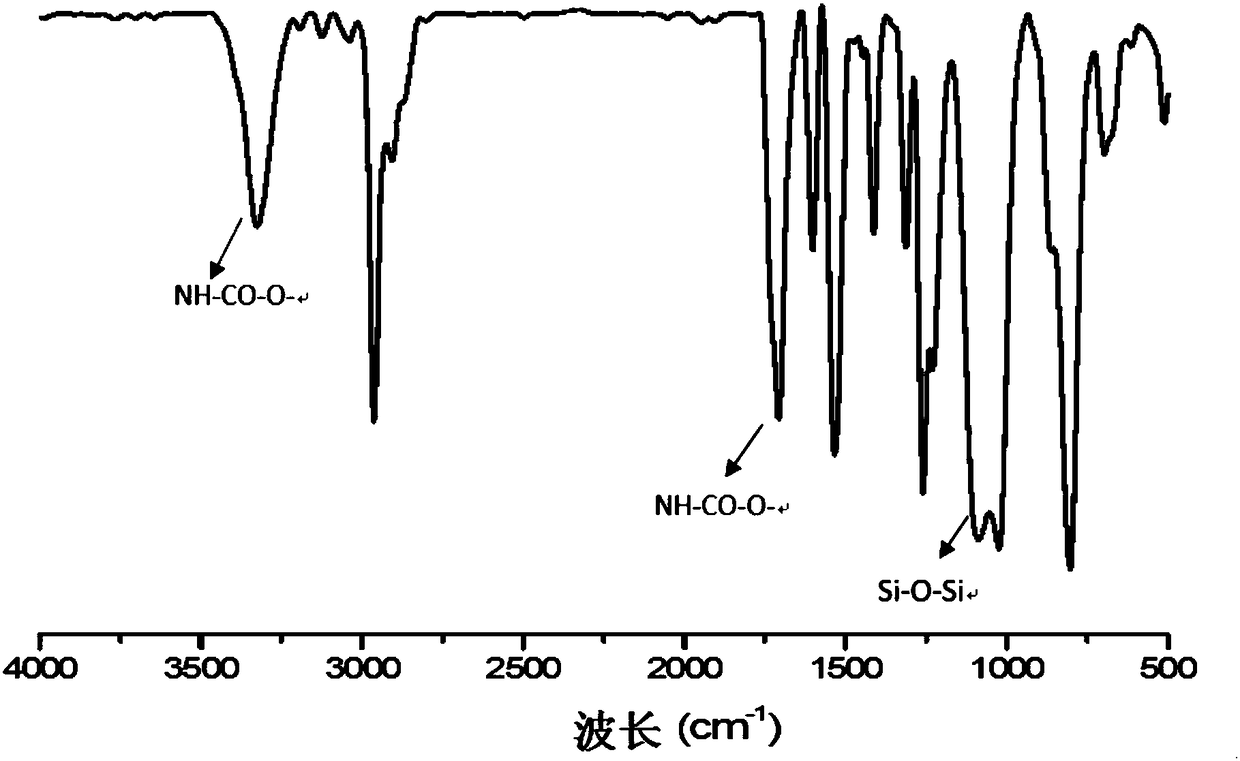

A polyurethane elastomer and organosilicon technology, which is applied in the synthesis of organosilicon polymer materials, can solve the problems of small degree of microphase separation of elastomers, irregular polymer structure, inability to guarantee mechanical properties, etc. Good capacitance, transparency and gloss, good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation method of organosilicon modified polyurethane elastomer, comprises steps as follows:

[0048] In a round-bottomed three-neck flask equipped with magnetic stirring, nitrogen gas feeding device and constant pressure dropping funnel, add 1.339g of diphenylmethane diisocyanate when the temperature rises to 60°C, and 2.5g of the relative molecule Hydroxypropyl polysiloxane with a mass of 2000 was added dropwise to the above solution through a dropping funnel, reacted at 80°C until the NCO content was stable, and a prepolymer was prepared. Amide and 1,4-dioxane, the volume ratio of N,N-dimethylacetamide to 1,4-dioxane is 2:1; a total of 15g is diluted, and finally 0.345g butanediol and 0.015g Dissolve stannous isooctanoate in a total of 15g of mixed solvent N,N-dimethylacetamide and 1,4-dioxane (volume ratio 2:1), and add it dropwise to the reactor through the dropping funnel, at 70°C The reaction was carried out for 60 minutes, the solvent was removed,...

Embodiment 2

[0056] A kind of preparation method of organosilicon modified polyurethane elastomer, comprises steps as follows:

[0057] In a round-bottomed three-neck flask equipped with magnetic stirring, nitrogen gas feeding device and constant pressure dropping funnel, when the temperature rose to 60°C, 1.339g of diphenylmethane diisocyanate was added, and under vigorous stirring, 3.33g of the relative molecule Hydroxypropyl polysiloxane with a mass of 4000 was added dropwise to the above solution through a dropping funnel, reacted at 80°C until the NCO content was stable, and a prepolymer was prepared, using N,N-dimethylformamide and A total of 20 g of tetrahydrofuran mixed solvent (volume ratio 2:1) was diluted, and finally 0.382 g of butanediol and 0.050 g of stannous isooctanoate were dissolved in mixed solvent N,N-dimethylformamide and tetrahydrofuran (volume ratio of 2:1 ) in a total of 20 g, was added dropwise into the reactor through a dropping funnel, reacted at 70°C for 100 mi...

Embodiment 3

[0060] A kind of preparation method of organosilicon modified polyurethane elastomer, comprises steps as follows:

[0061] In a three-necked round-bottomed flask equipped with magnetic stirring, nitrogen gas feeding device and constant pressure dropping funnel, when the temperature rose to 60°C, 1.011g of diphenylmethane diisocyanate was added, and under vigorous stirring, 2.510g of the relative molecule Hydroxypropyl polysiloxane with a mass of 2000 was added dropwise to the above solution through a dropping funnel, reacted at 80°C until the NCO content was stable, and a prepolymer was prepared, using N,N-dimethylformamide and A total of 15g of 1,4-dioxane mixed solvent (volume ratio 2:1) was diluted, and finally 0.230g of butanediol and 0.015g of stannous isooctanoate were dissolved in the mixed solvent of N,N-dimethylformamide and 1 , a total of 15g of 4-dioxane (volume ratio 2:1) was added dropwise into the reactor through the dropping funnel, and reacted at 70°C for 60min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com