Nano polyurethane adhesive and its preparation process

A polyurethane adhesive, nano-technology, applied in the field of nano-material modified polyurethane adhesive and its preparation, can solve the problems of intolerant plasticizer penetration, poor stability of production batches, poor adhesion, etc., and achieve simple operation process and high product quality Stabilization, initial tack and peel strength improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

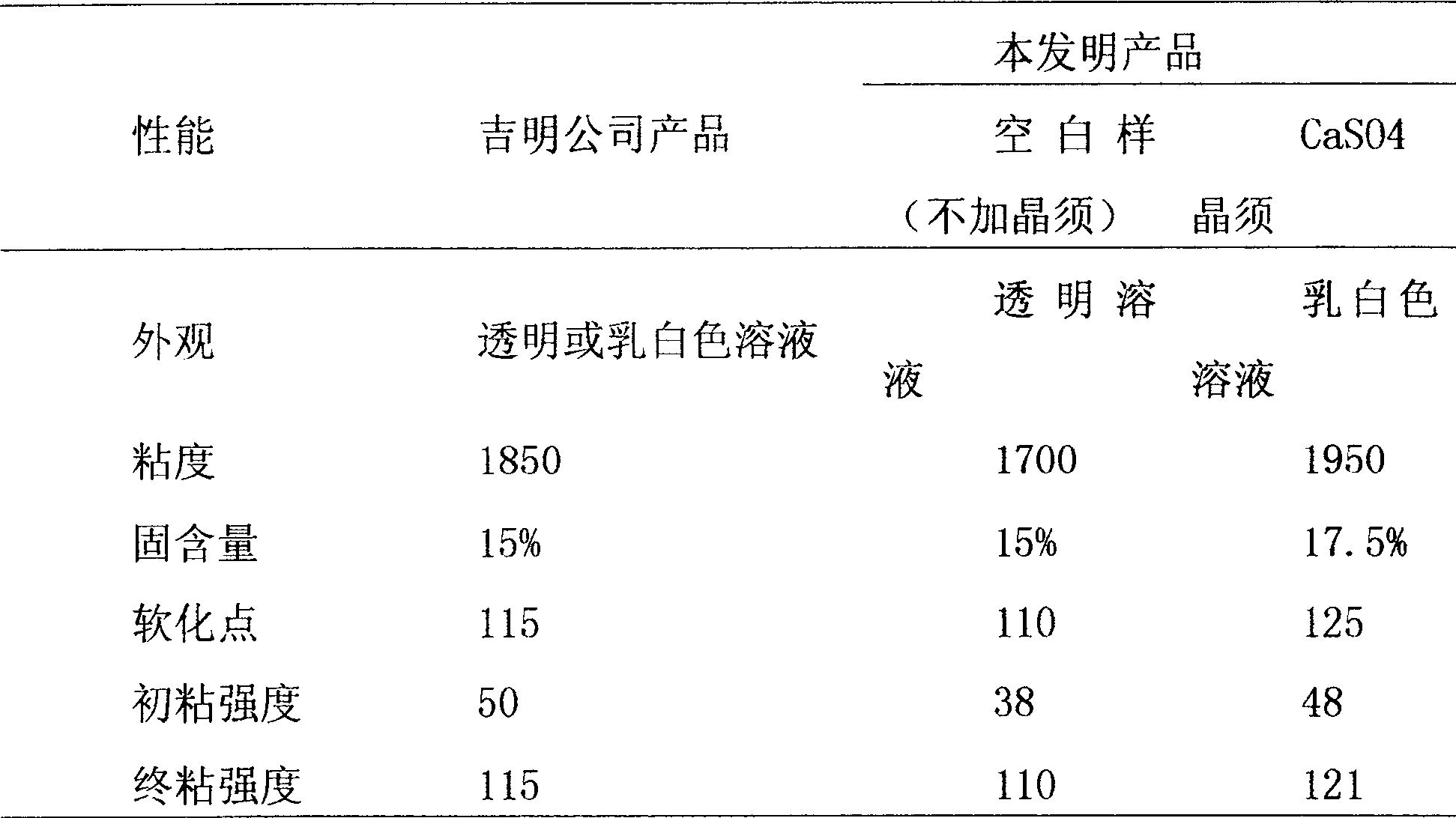

Embodiment 1

[0044] Prepare one-component solvent-based nano-polyurethane adhesive for shoes according to the following formula and process:

[0045] formula:

[0046] The hydroxyl-terminated polyester is a hydroxyl-terminated polyadipate-1,4-butanediol ester diol with an average molecular weight of 2500;

[0047] The isocyanate is toluene diisocyanate;

[0048] The solvent is a mixed solvent (butanone, acetone, and ethyl acetate are mixed in parts by mass 25:30:30);

[0049] The nano filler is 200nm CaSO4 whisker without chemical modification;

[0050] The catalyst is dibutyltin dilaurate;

[0051] Inhibitor is benzoyl chloride;

[0052] Preparation Process:

[0053] (1) Weigh 400g of adipic acid and the corresponding 1,4-butanediol into the reactor according to the acid-alcohol molar ratio of 1:1.0~1.2, and add the temperature to 140°C within 60 minutes, add 0.6g of catalyst, and Stir under the protection of nitrogen, separate water, and control the fractional distillation temperat...

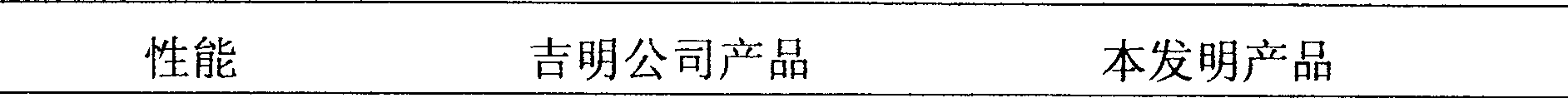

Embodiment 2

[0066] Prepare one-component solvent-based nano-polyurethane adhesive for shoes according to the following formula and process

[0067] formula:

[0068] The hydroxyl-terminated polyester is hydroxyl-terminated polyadipate-1,4-butanediol / 1,6-hexanediol ester diol with an average molecular weight of 3000;

[0069] The isocyanate is diphenylmethane diisocyanate;

[0070] The chain extender is 1,4-butanediol;

[0071] The solvent is a mixed solvent (butanone, acetone, and ethyl acetate are mixed in parts by mass 25:30:30);

[0072] The nano filler is chemically modified 200nm CaSO4 whisker;

[0073] The catalyst is dibutyltin dilaurate;

[0074] Inhibitor is benzoyl chloride;

[0075] Preparation Process:

[0076] (1) Weigh 400g of adipic acid and the corresponding 1,4-butanediol and 1,6-hexanediol (molar ratio of 1:3) into the reactor according to the acid-alcohol molar ratio of 1:1.0~1.2, Raise the temperature to 140°C within 60 minutes, add 0.6g of catalyst, stir under ...

Embodiment 3

[0091] Prepare one-component solvent-based nano-polyurethane adhesive for shoes according to the following formula and process

[0092] formula:

[0093] The hydroxyl-terminated polyester is a hydroxyl-terminated polyadipate-1,6-hexanediol ester diol with an average molecular weight of 2500

[0094] The isocyanate is 1,6-hexamethylene diisocyanate;

[0095] The chain extender is 1,4-butanediol;

[0096] The solvent is a mixed solvent (butanone, acetone, and ethyl acetate are mixed in parts by mass 25:30:30);

[0097] Nanofillers are nanoscale (<100nm=CaCO3 particles without chemical treatment;

[0098] Catalyst is diethanolamine;

[0099] Inhibitor is benzoyl chloride;

[0100] Preparation Process:

[0101] (1) Weigh 400g of adipic acid and the corresponding 1,6-hexanediol into the reactor according to the acid-alcohol molar ratio of 1:1.0~1.2, and add the temperature to 140°C within 60 minutes, add 0.6g of catalyst, and Stir under the protection of nitrogen, separate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com