Method for adjusting furnace charge structure before damping-down period of blast furnace for smelting high-titanium schreyerite

An adjustment method and technology of vanadium-titanium ore, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as abnormal furnace conditions, failure of furnace conditions to recover, affecting blast furnace technical and economic indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] at 1750m 3 The blast furnace is scheduled to have a wind break for 6 hours on the second day, and the wind break starts at 8:00 the next day. The specific examples are as follows:

[0039] Step 1: Calculation of Furnace Ratio

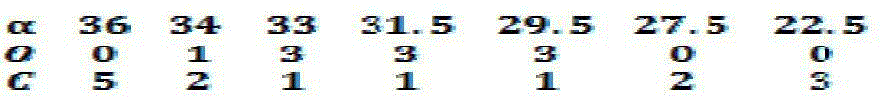

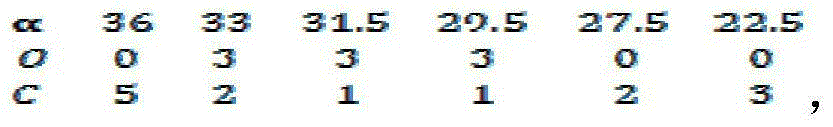

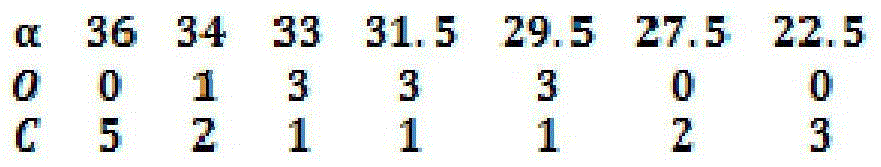

[0040] The charge structure before the material change is: 14% pellets + 3% lump ore + 83% sintered ore, the ore batch weight is 45 tons, and the coke load is 4.4 tons / ton; the charge distribution parameters are α 36 34 33 31.5 29.5 27.5 22.5 0 0 1 3 3 3 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com