High-wear-resistance glass explosion-proof film adhesive with anti-fog effect, and preparation method thereof

A technology of high wear-resistant and explosion-proof film, applied in the direction of adhesives, pressure-sensitive film/sheet, film/sheet release liner, etc., can solve problems such as limited application range, and achieve increased cross-linking density, hardness and wear resistance Sex, the effect of reducing the contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

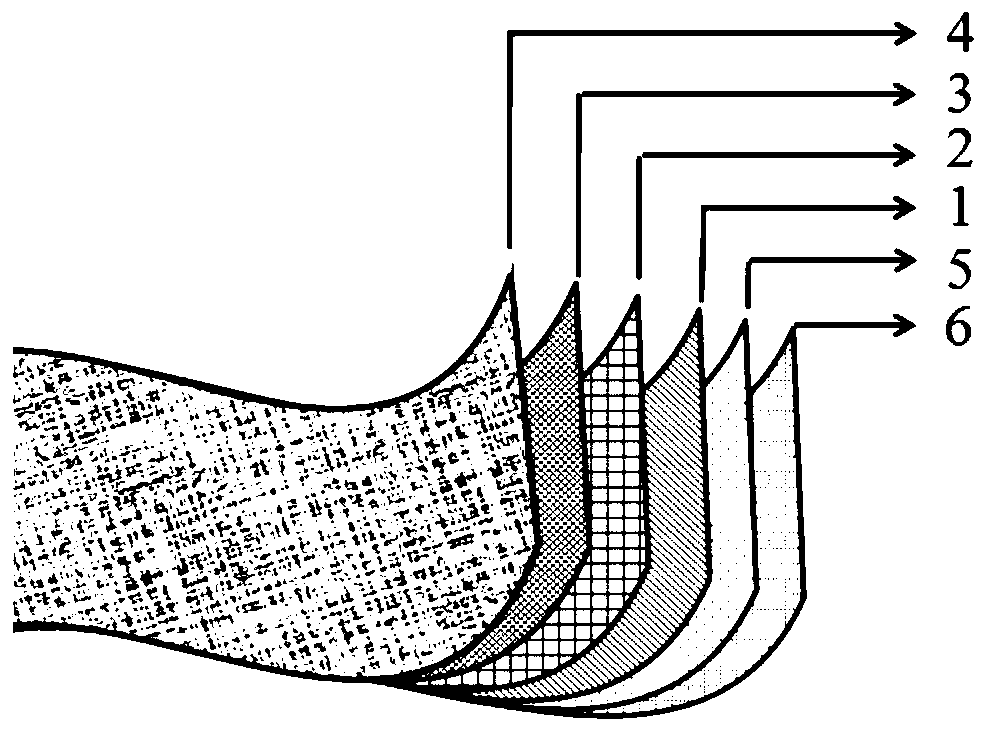

[0036] The present invention also provides a preparation method of the above-mentioned high wear-resistant glass explosion-proof film with anti-fog effect, comprising the following steps:

[0037] (1) prepare anti-fog wear-resistant resin coating;

[0038] (2) prepare high hardness transparent modified PET film;

[0039] (3) Coating polyacrylate precoat;

[0040] (4) Coating anti-fog and wear-resistant resin coating;

[0041] (5) Coating and installing adhesive layer.

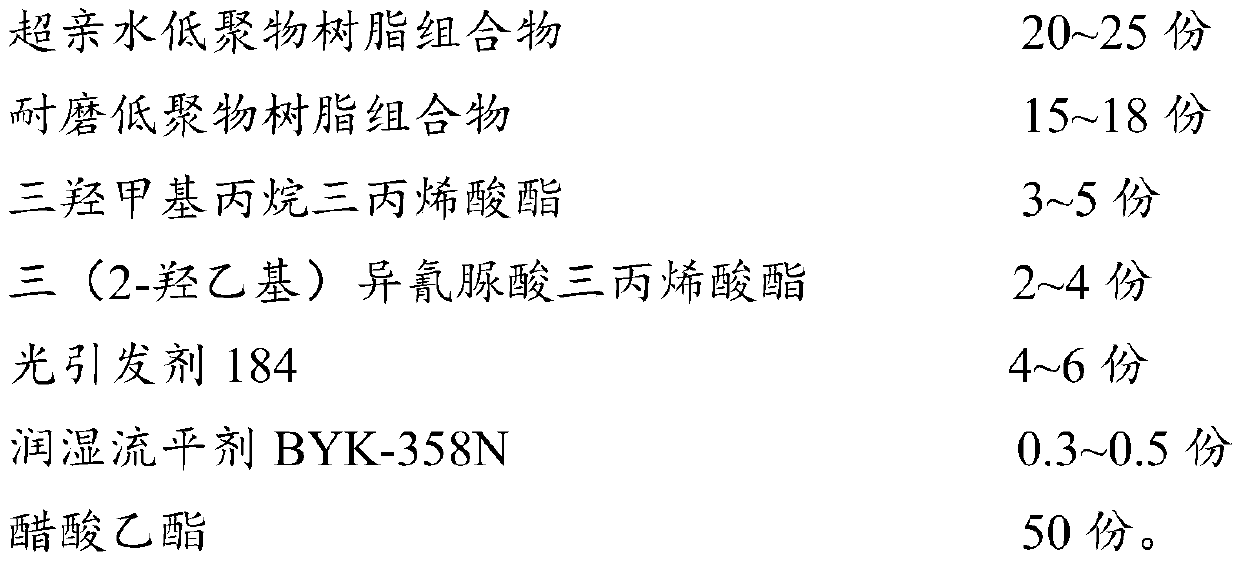

[0042] The preparation of the anti-fog wear-resistant resin coating comprises the following steps:

[0043] Weigh respectively superhydrophilic oligomer resin composition, wear-resistant oligomer resin composition, trimethylolpropane triacrylate, three (2-hydroxyethyl) isocyanurate triacrylate, photoinitiator 184. Wetting and leveling agent BYK-358N, ethyl acetate. Disperse and stir evenly in a light-proof container.

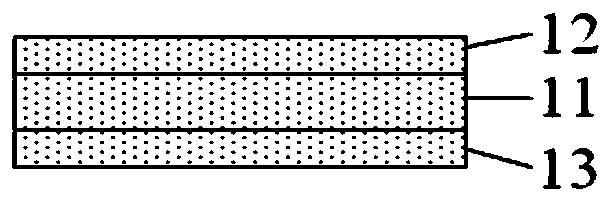

[0044] Described preparation high hardness transparent modified PET film comprises the ...

Embodiment 1

[0054] A preparation method of a high wear-resistant glass explosion-proof film with anti-fog effect, comprising the following steps:

[0055] (1) Preparation of anti-fog wear-resistant resin:

[0056] Use the following parts by mass of raw materials to disperse and stir in a light-proof container for further use:

[0057] 17 parts of polyethylene glycol dimethacrylate, 6 parts of polyethylene glycol monomethyl ether methacrylate, 12 parts of trifunctional super-tough resin FSP8060, 4 parts of ten-functional polyurethane acrylate oligomer FSP2159, trimethylol 4 parts of propane triacrylate, 2.7 parts of tris(2-hydroxyethyl)isocyanurate triacrylate, 4 parts of photoinitiator 184, 0.3 parts of wetting and leveling agent BYK-358N, 50 parts of ethyl acetate .

[0058] (2) Preparation of high hardness transparent modified PET film 1:

[0059] The raw material components corresponding to the upper surface layer, middle layer and lower surface layer of the three screw extruders we...

Embodiment 2

[0072] A preparation method of a high wear-resistant glass explosion-proof film with anti-fog effect, comprising the following steps:

[0073] (1) Preparation of anti-fog wear-resistant resin:

[0074] Use the following parts by mass of raw materials to disperse and stir in a light-proof container for further use:

[0075] 19 parts of polyethylene glycol bismethacrylate, 3 parts of polyethylene glycol bismaleate, 12 parts of trifunctional super-tough resin FSP8060, 3 parts of polyurethane acrylate oligomer CN996NS, trimethylolpropane triacrylic acid 3 parts of ester, 4.5 parts of tris(2-hydroxyethyl)isocyanurate triacrylate, 5 parts of photoinitiator 184, 0.5 parts of wetting and leveling agent BYK-358N, 50 parts of ethyl acetate.

[0076] (2) Preparation of high hardness transparent modified PET film 1:

[0077] The raw material components corresponding to the upper surface layer, middle layer and lower surface layer of the three screw extruders were weighed in the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com