Process for preparing binder-free formed activated carbon from waste biomass

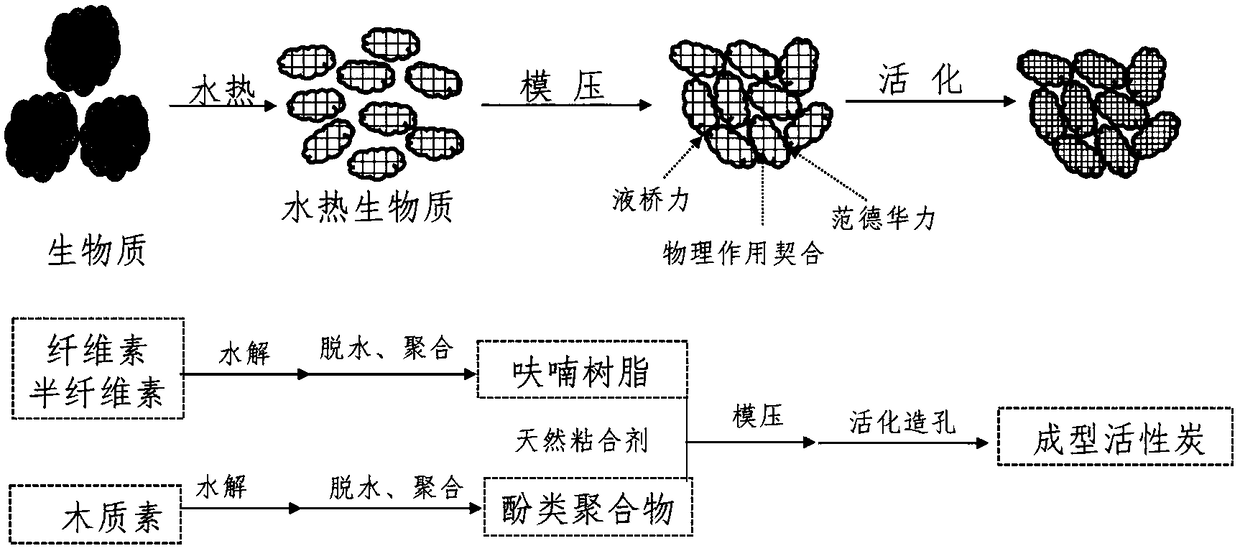

A technology for forming activated carbon and waste biomass, which is applied in the direction of carbon compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of high preparation cost and poor forming performance of powder activated carbon binder, and achieve low cost and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

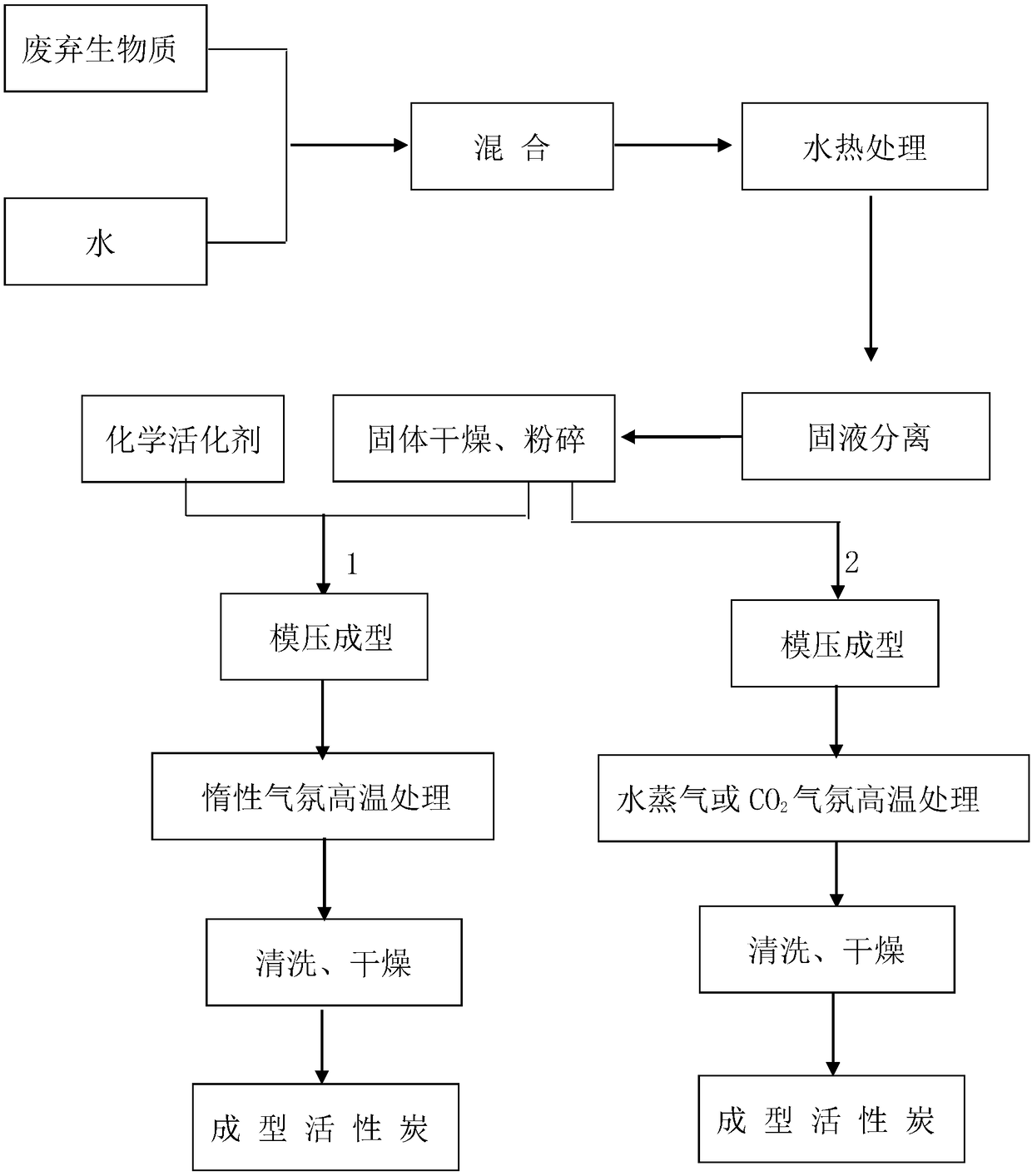

Method used

Image

Examples

Embodiment 1

[0027] 1. Material preparation

[0028] Cotton stalks are used as waste biomass, and the stalks are dried and crushed to 80 mesh for later use;

[0029] 2. Preparation of Shaped Activated Carbon

[0030] 1) Fully mix cotton stalks (dry basis) and water at a ratio of 1:5;

[0031] 2) After the mixture is transferred to the hydrothermal reaction kettle, seal it;

[0032] 3) Heat the reactor to 220°C for hydrothermal treatment, stop heating after 60 minutes of hydrothermal treatment, and naturally cool to room temperature;

[0033] 4) The mixture in the reactor is centrifuged to separate the solid waste to obtain a solid product;

[0034] 5) After the solid product is dried at room temperature, it is fully mixed with potassium hydroxide according to the mass ratio of 1:2 (solid physical mixing);

[0035] 6) After mixing, keep it under the molding pressure of 5Mpa for 1min and then release the mold (cylindrical shape with a length of 2cm and a diameter of 1.5cm);

[0036] 7) ...

Embodiment 2

[0042] 1. Material preparation

[0043] The waste biomass is made of bamboo chips, and the bamboo chips are dried and crushed to 80 mesh for later use;

[0044] 2. Preparation of Shaped Activated Carbon

[0045] 1) Fully mix bamboo chips (dry basis) and water at a ratio of 1:4;

[0046] 2) After the mixture is transferred to the hydrothermal reaction kettle, seal it;

[0047] 3) Heat the reactor to 250°C for hydrothermal treatment, stop heating after 40 minutes of hydrothermal treatment, and naturally cool to room temperature;

[0048] 4) The mixture in the reactor is centrifuged to separate the solid waste to obtain a solid product;

[0049] 5) After the solid product is dried at room temperature, it is fully mixed with potassium hydroxide according to the mass ratio of 1:3 (the potassium hydroxide is made into a solution and then mixed), and after mixing, it is dried at 80°C for 12 hours;

[0050] 6) After drying, keep it under the molding pressure of 4Mpa for 0.5min and t...

Embodiment 3

[0055] 1. Material preparation

[0056] The waste biomass is made of bamboo chips, which are dried and crushed to 80 meshes for later use;

[0057] 2. Preparation of Shaped Activated Carbon

[0058] 1) Fully mix bamboo chips (dry basis) and water at a ratio of 1:4;

[0059] 2) After the mixture is transferred to the hydrothermal reaction kettle, seal it;

[0060] 3) Heat the reactor to 250°C for hydrothermal treatment, stop heating after 40 minutes of hydrothermal treatment, and naturally cool to room temperature;

[0061] 4) After the mixture in the reaction kettle is centrifuged to separate the solid waste, a solid product is obtained and dried;

[0062] 5) After drying, keep it under the molding pressure of 4Mpa for 0.5min and then release the mold (cylindrical shape with a length of 2cm and a diameter of 1.5cm);

[0063] 7) The molded body is heated to 800°C at a heating rate of 10°C / min in a nitrogen atmosphere, and then the nitrogen is changed to CO 2 , CO 2 Flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com