Waterborne polyurethane dispersion and application thereof

A water-based polyurethane and dispersion technology, applied in the field of coatings, can solve the problems of toxicity, high price, restrictions, etc., and achieve the effect of improving weather resistance and great promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

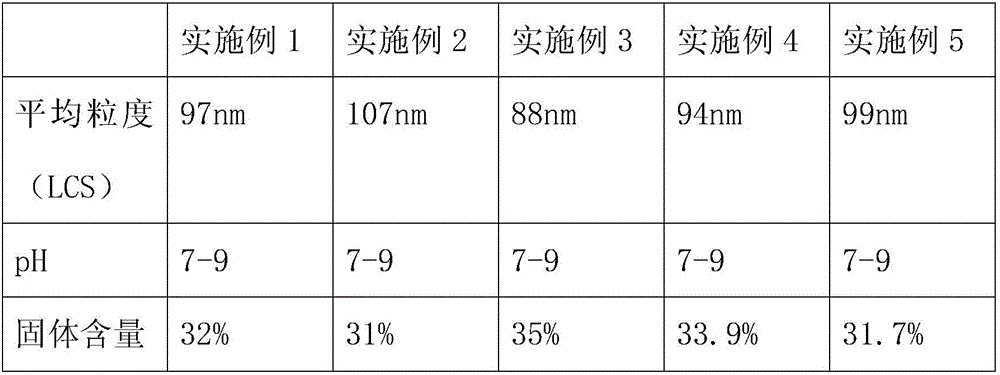

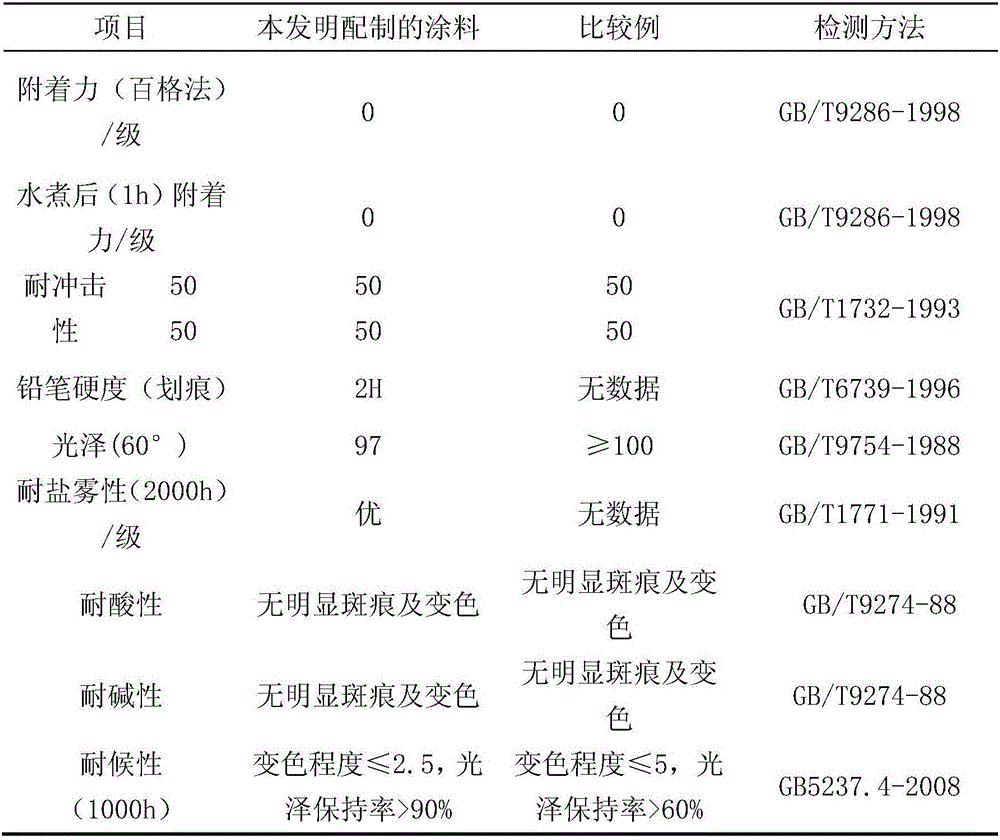

Examples

preparation example Construction

[0064] In the preparation of the prepolymer, the isocyanate index is 1.0-4.0, preferably 1.1-3.5, more preferably 1.2-3.0. During the preparation, the monomers can be completely reacted or partially reacted, preferably completely reacted. In this way, polyurethane prepolymers containing free isocyanate groups are obtained in bulk or in solution.

[0065] The aqueous polyurethane dispersion is prepared by adding water to the prepolymer or adding the prepolymer to water, preferably adding water to the prepolymer. If the prepared prepolymer is difficult to disperse, use aliphatic ketones such as acetone or methyl ethyl ketone for viscosity reduction.

[0066] Subsequently, the -NH-containing 2 The functional or -NH functional component reacts with the remaining isocyanate groups. This step can be performed in a solvent or in water before, during and after dispersion. Use conforming to the definition of component C), containing -NH 2 It is preferable to carry out the chain ex...

Embodiment 1

[0082] Example 1 A kind of aqueous polyurethane dispersion

[0083] B) component 236g polytetrahydrofuran polyol (Mn=1000), D) component 17.6g dimethylol butyric acid, C) component 5.3g 1,3-butanediol, C) component 3.8g neopentyl Add diol and 150g of acetone into the reactor, heat to 60°C, and stir. Then A) component 74.5 g of hexamethylene diisocyanate (HDI) and F) component 1.4 g of dibutyltin dilaurate were added and the mixture was heated to 70°C. Stirring was carried out at this temperature until the NCO content reached 8.1%. Then, the mixture was cooled to 50° C., and then 9.2 g of triethylamine, component E), was added and stirred for 30 min. The prepolymer was dispersed in 750 g of water, and the water was added at 0°C. After dispersion, stir for another 10 min. An aqueous solution (60 g) of C) component 1.2 g of hydrazine hydrate and C) component of 1.6 g of ethylenediamine was then added within 10 min. After complete addition of the aqueous solution, the mixtur...

Embodiment 2

[0084] Example 2 A kind of aqueous polyurethane dispersion

[0085] B) component 245g polytetrahydrofuran polyol (Mn=1000), B) component 100g polycarbonate polyol (Mn=2000), D) component 16.7g dimethylol propionic acid, C) component 5.2 g1,3-butanediol, C) component 3.6g neopentyl glycol and 150g acetone were added into the reactor, heated to 60°C and stirred. Then add A) component 34.1 g hexamethylene diisocyanate (HDI), A) component 40.4 g isophorone diisocyanate and F) component 1.3 g dibutyltin dilaurate, and heat the mixture to 70°C . Stirring was carried out at this temperature until the NCO content reached 7.4%. Then, the mixture was cooled to 50° C., and then 8.9 g of triethylamine, component E), was added and stirred for 30 min. The prepolymer was dispersed in 750 g of water, and the water was added at 0°C. After dispersion, stir for another 10 min. Then an aqueous solution (60 g) of C) component 1.2 g of hydrazine hydrate C) component and 1.8 g of ethylenediam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com