Preparation method of force-electricity-light conversion enhanced luminous composite thin film

A composite film, light conversion technology, applied in chemical instruments and methods, luminescent materials, filament/wire forming, etc., can solve problems such as limited force and weak fluorescence emission, and achieve enhanced interaction force, enhanced luminous intensity, environmental protection, etc. Stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for preparing a force-electricity-light conversion enhanced luminescent composite film, the specific steps are as follows:

[0054] (1) 0.5mol / L of Sr(NO 3 ) 2 and Al(NO 3 ) 3 , 0.02mol / L of Eu(NO 3 ) 3 and Dy(NO 3 ) 3 Stoichiometric ratio Sr 0.97 Al 2 o 4 :Eu 2+ 0.01 , Dy 3+ 0.02 (abbreviated as SAOE) into the beaker and stir evenly, add precipitant urea, dispersant ethylene glycol, surfactant CTAB for ultrasonic dispersion, and transfer the ultrasonically dispersed solution into a stainless steel reaction kettle with polytetrafluoroethylene at 145 Under the temperature condition of ℃, carry out hydrothermal reaction, centrifuge and dry after reacting for 24 hours to obtain the precursor powder;

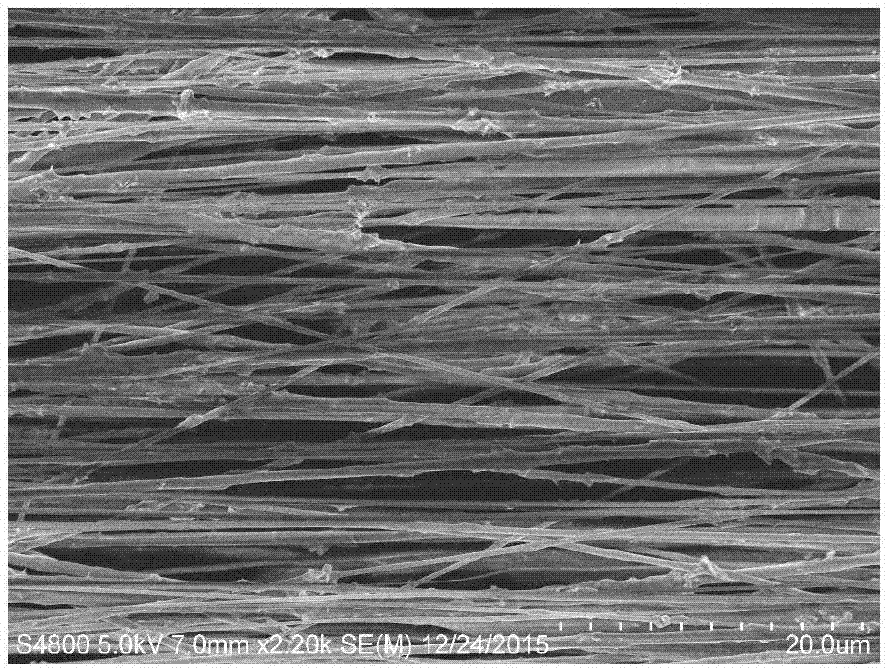

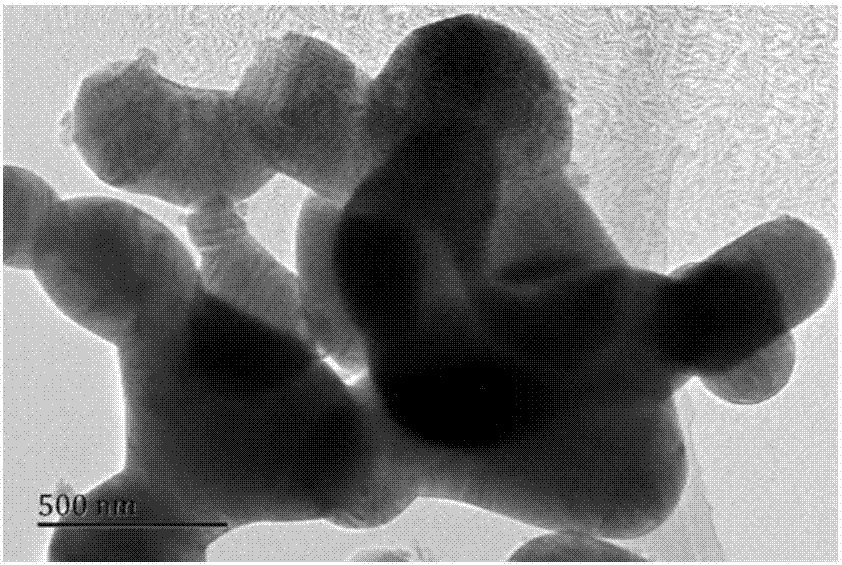

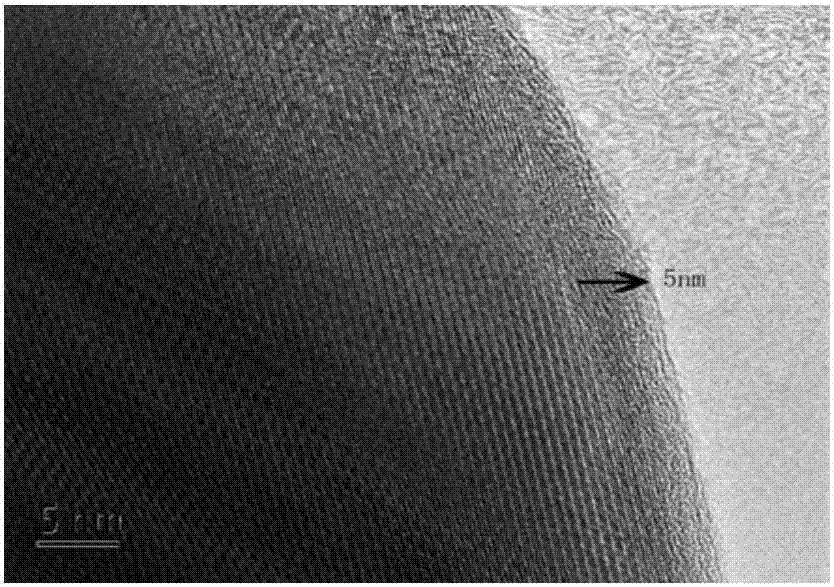

[0055] (2) Put the precursor powder into the 2 In a tube furnace with a reducing atmosphere of 5% argon by volume, the tube furnace operates at 5°C min -1 Burn at 1300°C for 4 hours at a heating rate to obtain spherical Sr 0.97 Al 2 o 4 :Eu 2+ 0....

Embodiment 2

[0062] A method for preparing a force-electricity-light conversion enhanced luminescent composite film, the specific steps are as follows:

[0063] (1) 0.5mol / L of Sr(NO 3 ) 2 and Al(NO 3 ) 3 , 0.02mol / L of Eu(NO 3 ) 3 and Dy(NO 3 ) 3 Stoichiometric ratio Sr 0.97 Al 2 o 4 :Eu 2+ 0.01 , Dy 3+ 0.02 (abbreviated as SAOE) into the beaker and stir evenly, add precipitant urea, dispersant ethylene glycol, surfactant CTAB for ultrasonic dispersion, and transfer the ultrasonically dispersed solution into a stainless steel reaction kettle with polytetrafluoroethylene at 145 Under the temperature condition of ℃, carry out the hydrothermal reaction, and react for 24 hours, centrifuge and dry to obtain the precursor powder;

[0064] (2) Put the precursor powder into the 2 In a tube furnace with a reducing atmosphere of 5% argon by volume, the tube furnace operates at 5°C min -1Burn at 1300°C for 4 hours at a heating rate to obtain spherical Sr 0.97 Al 2 o 4 :Eu 2+ 0.0...

Embodiment 3

[0069] A method for preparing a force-electricity-light conversion enhanced luminescent composite film, the specific steps are as follows:

[0070] (1) Burn 0.5mol / L of Sr(NO 3 ) 2 and Al(NO 3 ) 3 , 0.02mol / L of Eu(NO 3 ) 3 and Dy(NO 3 ) 3 Stoichiometric ratio Sr 0.97 Al 2 o 4 :Eu 2+ 0.01 , Dy 3+ 0.02 (abbreviated as SAOE) into the beaker and stir evenly, add the combustion agent triethylamine, put the ultrasonically dispersed solution into the muffle furnace and heat it to 300 ° C for 40 minutes, and then continue to burn in the muffle furnace at 700 ° C Under oxidation treatment for 3 hours, the precursor powder was obtained;

[0071] (2) Put the precursor powder into the 2 In a tube furnace with a reducing atmosphere of 5% argon by volume, the tube furnace operates at 5°C min -1 Burn at 1300°C for 4 hours at a heating rate to obtain flaky Sr 0.97 Al 2 o 4 :Eu 2+ 0.01 , Dy 3+ 0.02 (abbreviated as SAOED);

[0072] (3) Add 0.01g / mL ethanol solution of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com