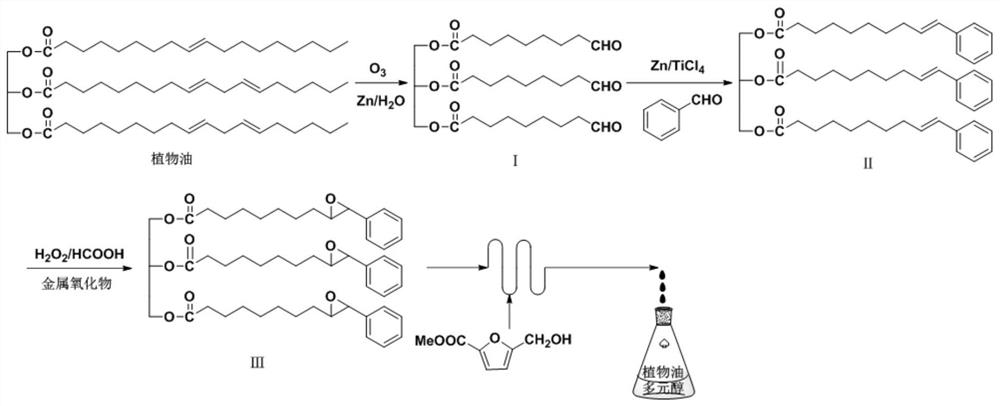

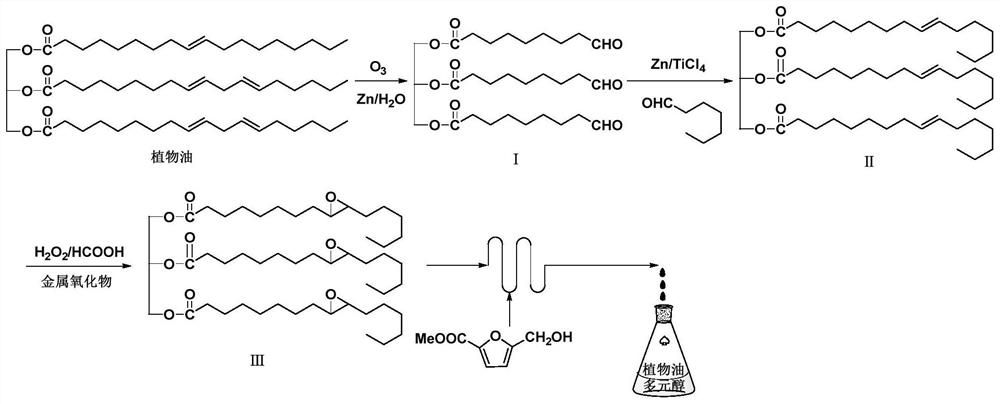

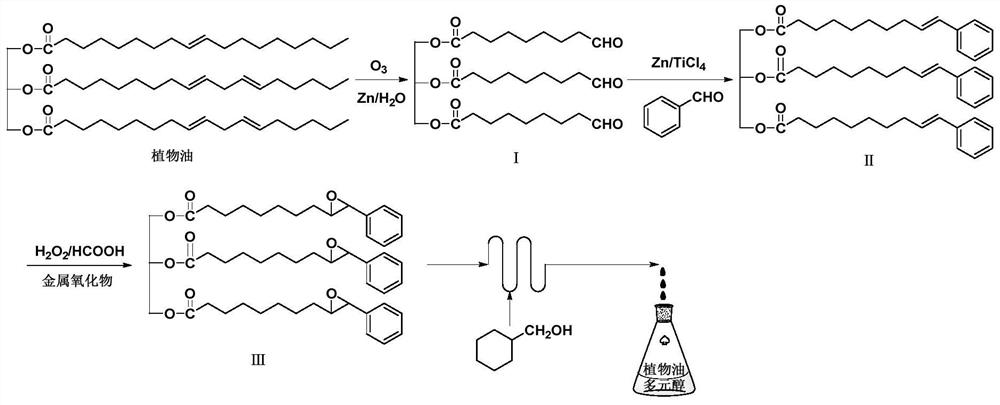

A kind of vegetable oil polyol without suspension chain, preparation method and application

A vegetable oil polyol and vegetable oil technology, applied in the field of preparation and vegetable oil polyol, can solve the problems of high viscosity and large hydroxyl value, and achieve the effects of high tear strength, low density, moderate hydroxyl value and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of peanut oil polyol

[0038]10g of peanut oil and 40mL of deionized water were added to a five-necked flask equipped with a mechanical stirrer, a condensing reflux tube, an infrared probe, and a thermometer. Under vigorous stirring, the ozone generated by the ozone generator was passed into the reaction system to carry out the ozonation reaction. Tail gas is absorbed by potassium iodide solution, the amount of ozone introduced is 0.4L / min, react at 20°C for 8 hours, and after post-treatment, peanut oil derivative I without suspended chains can be obtained;

[0039] Under nitrogen protection, use tetrahydrofuran as a solvent, add a certain amount of zinc powder into a three-necked flask, cool the reaction solution to zero, add a certain amount of titanium tetrachloride dropwise, and reflux for 3 hours, cool the reaction solution, and add to the reaction solution A certain amount of pyridine was slowly added to the reaction liquid, and after 20 minutes of...

Embodiment 2

[0048] (1) According to figure 1 The synthetic process flow chart shown prepares cottonseed oil polyol:

[0049] Add 10g of cottonseed oil and 40mL of deionized water into a five-necked flask equipped with a mechanical stirrer, a condensing reflux tube, an infrared probe, and a thermometer. Under vigorous stirring, the ozone generated by the ozone generator is passed into the reaction system for ozonation reaction , the tail gas is absorbed by potassium iodide solution, the ozone flux is 0.6L / min, react at 20°C for 10h, and after post-treatment, the cottonseed oil derivative I without suspended chains can be obtained;

[0050] Under nitrogen protection, use tetrahydrofuran as a solvent, add a certain amount of zinc powder into a three-necked flask, cool the reaction solution to zero, add a certain amount of titanium tetrachloride dropwise, and reflux for 3 hours, cool the reaction solution, and add to the reaction solution A certain amount of pyridine was slowly added to the ...

Embodiment 3

[0059] (1) Preparation of castor oil polyol

[0060] Add 10g of castor oil and 40mL of deionized water into a five-necked flask equipped with a mechanical stirrer, a condensing reflux tube, an infrared probe, and a thermometer. Under vigorous stirring, the ozone generated by the ozone generator is passed into the reaction system for ozonation reaction , the tail gas is absorbed by potassium iodide solution, the ozone flux is 0.6L / min, react at 20°C for 10h, and the castor oil derivative I without dangling chains can be obtained after post-treatment;

[0061] Under nitrogen protection, use tetrahydrofuran as a solvent, add a certain amount of zinc powder into a three-necked flask, cool the reaction solution to zero, add a certain amount of titanium tetrachloride dropwise, and reflux for 3 hours, cool the reaction solution, and add to the reaction solution A certain amount of pyridine was slowly added to the reaction liquid, and after reacting for 20 minutes, castor oil derivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com