Manufacturing method of wood-plastic composite material with improved weather resistance

A technology of wood-plastic composite materials and thermoplastics, applied in the field of wood-plastic materials and their preparation, to achieve the effects of reducing thermal expansion coefficient, reducing stress, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

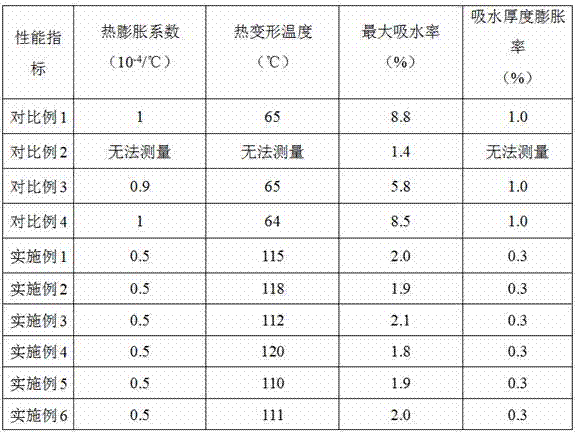

Examples

Embodiment 1

[0030] (1) Prepare materials according to the following components by mass:

[0031] 10 parts of polystyrene, 20 parts of high-density polyethylene, 10 parts of low-density polyethylene, 60 parts of polyethylene, 100 parts of wood flour, 2 parts of stearate, 1 part of paraffin wax, 5 parts of polyethylene wax, maleic anhydride 1 part of grafted polystyrene, 14 parts of maleic anhydride grafted polyethylene;

[0032] (2) Mixing the components in step (1) uniformly to obtain a mixed material;

[0033] (3) Carry out carbonization granulation and carbonization extrusion on the mixed material in step (2) in a twin-screw extrusion granulator, and the carbonization granulation and carbonization extrusion are carried out in the conventional multi-stage granulation and multi-stage extrusion process In the process, the temperature of the highest temperature section is raised to 250-260°C, the speed is 30r / min, and then the wood-plastic material is obtained through conventional cooling,...

Embodiment 2

[0035] (1) Prepare materials according to the following components by mass:

[0036] 40 parts of polypropylene, 10 parts of polyvinyl chloride, 10 parts of polystyrene, 10 parts of polyoxymethylene, 10 parts of polycarbonate, 20 parts of polyamide, 150 parts of bamboo powder, 5 parts of polypropylene wax, 4 parts of titanate, 6 parts of one or several kinds of maleic anhydride grafted polypropylene;

[0037] (2) Mixing the components in step (1) uniformly to obtain a mixed material;

[0038] (3) Carry out carbonization granulation and carbonization extrusion on the mixed material in step (2) in a twin-screw extrusion granulator, and the carbonization granulation and carbonization extrusion are carried out in the conventional multi-stage granulation and multi-stage extrusion process Among them, the temperature of the highest temperature section is raised to 260-270°C, the speed is 20r / min, and then the wood-plastic material is obtained through conventional cooling, traction, a...

Embodiment 3

[0040] (1) Prepare materials according to the following components by mass:

[0041] 10 parts of acrylic plastic, 10 parts of polysulfone, 10 parts of polyphenylene ether, 10 parts of polyethylene terephthalate, 10 parts of polybutylene terephthalate, 10 parts of polyphenylene sulfide, polyether 10 parts of sulfone, 10 parts of polyether ether ketone, 20 parts of thermoplastic polyimide, 200 parts of crop straw powder, 2 parts of stearic acid, 2 parts of stearate, 4 parts of titanate, 16 parts of isocyanate;

[0042] (2) Mixing the components in step (1) uniformly to obtain a mixed material;

[0043] (3) Carry out carbonization granulation and carbonization extrusion on the mixed material in step (2) in a twin-screw extrusion granulator, and the carbonization granulation and carbonization extrusion are carried out in the conventional multi-stage granulation and multi-stage extrusion process In the process, the temperature of the highest temperature section is raised to 270-28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com