Diesel oil-resisting low pressure change nitrile rubber material and preparation method thereof

A rubber material, nitrile rubber technology, applied in the field of rubber, to achieve excellent oil resistance, excellent oil resistance, low temperature resistance and excellent pressure change performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

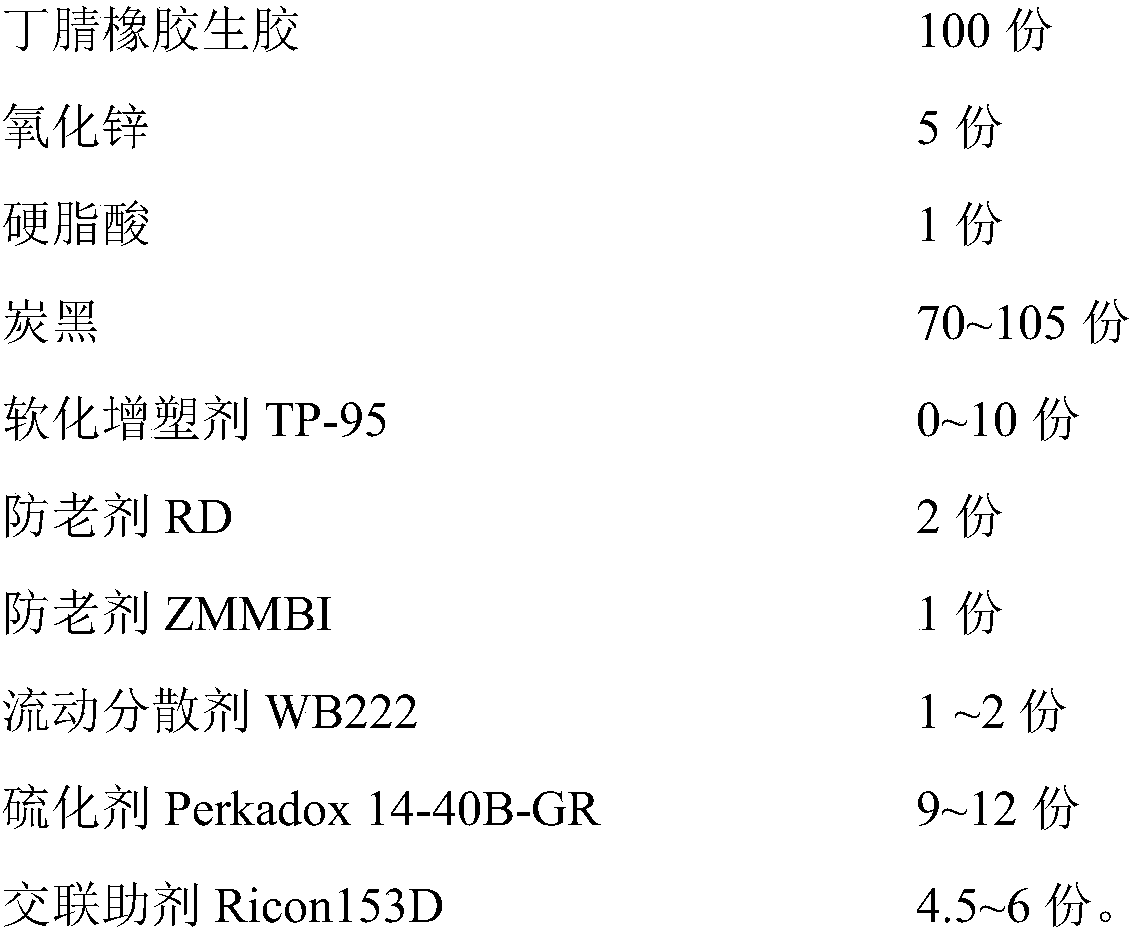

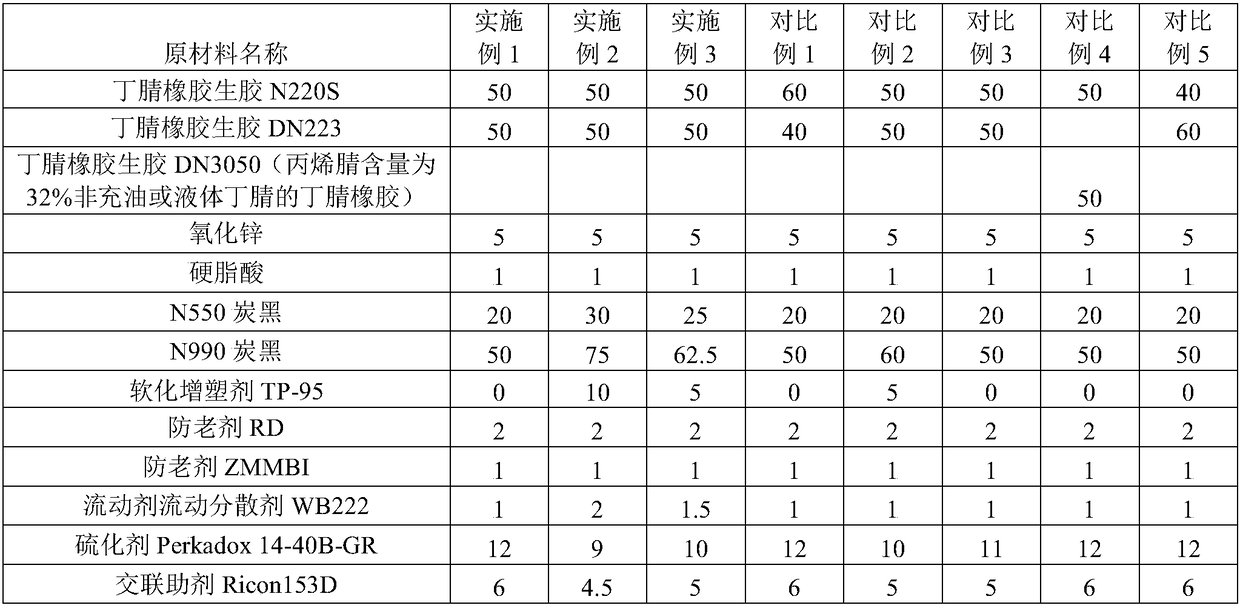

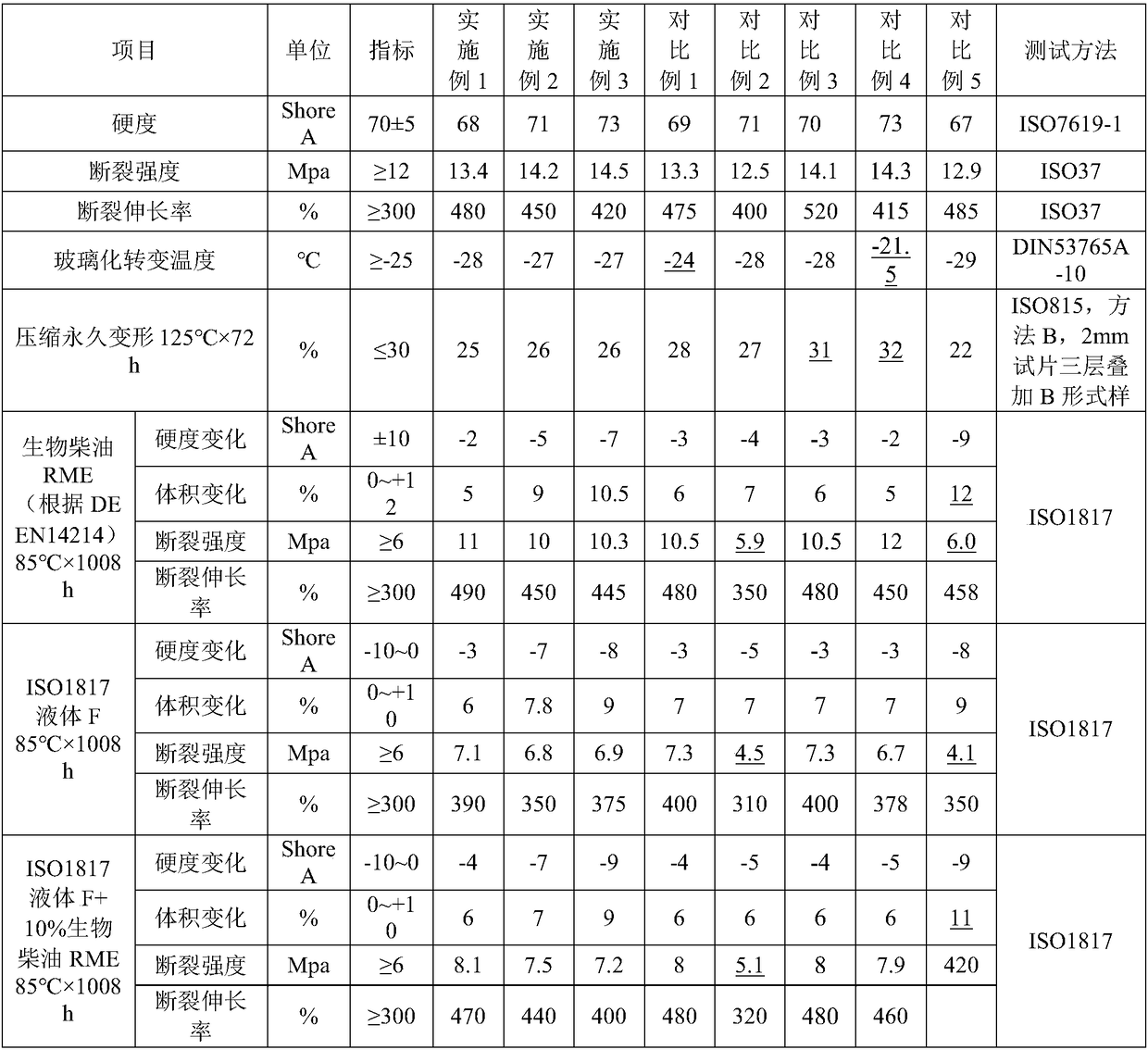

[0034] A kind of diesel oil-resistant low-pressure variable nitrile rubber material of the present embodiment comprises following components:

[0035] 50 parts of nitrile rubber raw rubber N220S, 50 parts of nitrile rubber raw rubber DN223, 5 parts of zinc oxide, 1 part of stearic acid, 20 parts of carbon black N550, 50 parts of carbon black N990, 0 parts of softening plasticizer TP-95 , 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, 1 part of flow dispersant WB222, 12 parts of vulcanizing agent Perkadox 14-40B-GR, 6 parts of cross-linking aid Ricon153D.

[0036] The process of preparing the low-pressure variable nitrile rubber material resistant to diesel oil in this embodiment is:

[0037] Step 1. Masterbatch mixing: prepare materials according to the above formula, send all raw materials except the crosslinking aid Ricon 153D and vulcanizing agent Perkadox14-40B-GR into the internal mixer for internal mixing to obtain the masterbatch;

[0038] Step 2, ma...

Embodiment 2

[0041] A kind of diesel oil-resistant low-pressure variable nitrile rubber material of the present embodiment comprises following components:

[0042] 50 parts of nitrile rubber raw rubber N220S, 50 parts of nitrile rubber raw rubber DN223, 5 parts of zinc oxide, 1 part of stearic acid, 30 parts of carbon black N550, 75 parts of carbon black N990, 10 parts of softening plasticizer TP-95 , 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, 2 parts of flow dispersant WB222, 9 parts of vulcanizing agent Perkadox 14-40B-GR, 4.5 parts of cross-linking aid Ricon153D.

[0043] The process of preparing the low-pressure variable nitrile rubber material resistant to diesel oil in this embodiment is:

[0044] Step 1. Masterbatch mixing: prepare materials according to the above formula, send all raw materials except the crosslinking aid Ricon 153D and vulcanizing agent Perkadox14-40B-GR into the internal mixer for internal mixing to obtain the masterbatch;

[0045] Step 2,...

Embodiment 3

[0048] A kind of diesel oil-resistant low-pressure variable nitrile rubber material of the present embodiment comprises following components:

[0049] 50 parts of nitrile rubber raw rubber N220S, 50 parts of nitrile rubber raw rubber DN223, 5 parts of zinc oxide, 1 part of stearic acid, 25 parts of carbon black N550, 62.5 parts of carbon black N990, 5 parts of softening plasticizer TP-95 , 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, 1.5 parts of flow dispersant WB222, 10 parts of vulcanizing agent Perkadox 14-40B-GR, 5 parts of cross-linking aid Ricon153D.

[0050] The process of preparing the low-pressure variable nitrile rubber material resistant to diesel oil in this embodiment is:

[0051] Step 1. Masterbatch mixing: prepare materials according to the above formula, send all raw materials except the crosslinking aid Ricon 153D and vulcanizing agent Perkadox14-40B-GR into the internal mixer for internal mixing to obtain the masterbatch;

[0052] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com