Copper-silver micro-nano multi-stage structure super-hydrophobic surface and production method thereof

A super-hydrophobic surface, silver micro-nano technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of molecular failure, hydrophobic film easy to fall off, easy to fall off, etc., to achieve good stability, preparation The method is simple and the hydrophobic performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

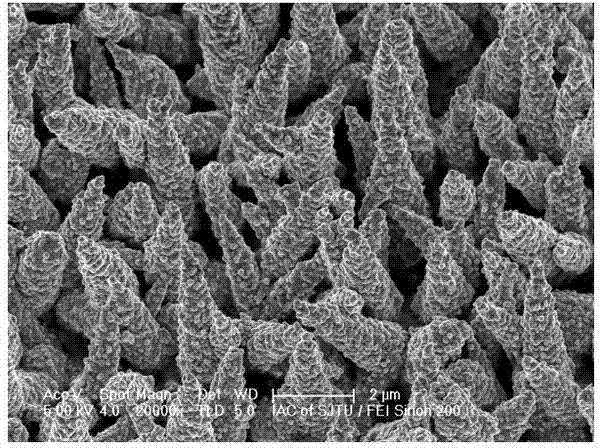

Image

Examples

Embodiment 1

[0030] The following method is used to prepare a super-hydrophobic surface with metallic copper-silver micro-nano hierarchical structure:

[0031] (1) Select copper sheet as the metal substrate, and degrease and pickle the surface;

[0032] (2) Put the metal substrate treated in step (1) in PdCl with a concentration of 0.15g / L 2 Activation treatment in solution;

[0033] (3) Put the metal substrate activated in step (2) into the electroless plating solution for chemical deposition. The composition and concentration of the chemical deposition solution are: copper sulfate 0.05 mol / L, nickel sulfate 0.008 mol / L, Trisodium citrate 0.08mol / L, boric acid 0.5mol / L, sodium hypophosphite 0.4 mol / L, and polyethylene glycol 15ppm, adjust pH to 9 with sodium hydroxide, chemical deposition temperature is 50°C, chemical deposition The time is 25 minutes;

[0034] (4) The metal substrate obtained by copper chemical deposition in step (3) is washed with deionized water, then dried, and the...

Embodiment 2

[0046] According to the method of Example 1, the concentration of the n-hexadecanethiol solution is changed to 0.03mol / L, and the metal copper silver micro-nano multi-level structure superhydrophobic surface prepared has a contact angle with water of 165 °, and a rolling angle less than 10°.

[0047]

Embodiment 3

[0049] The following method is used to prepare the super-hydrophobic surface of metallic copper-silver micro-nano hierarchical structure:

[0050] (1) Aluminum sheet is selected as the metal substrate, and its surface is degreased and pickled;

[0051] (2) Put the metal substrate treated in step (1) in 0.35g / L PdCl 2 Activation treatment in solution;

[0052] (3) Place the metal substrate activated in step (2) in the copper plating chemical deposition solution for chemical deposition. The composition and concentration of the copper plating chemical deposition solution are: copper chloride 0.02 mol / L, nickel chloride 0.01mol / L, malic acid 0.08mol / L, boric acid 0.2mol / L, sodium hypophosphite 0.2mol / L, and polypropylene glycol 5ppm, adjust the pH to 8 with potassium hydroxide, the temperature of chemical deposition is 20 ℃, chemical Deposition time is 60min;

[0053] (4) The metal substrate obtained by copper chemical deposition in step (3) is washed with deionized water, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com