Low temperature resistant high elasticity chlorinated polyethylene power line jacket material as well as preparation method thereof

A chlorinated polyethylene, high-elasticity technology, used in circuits, electrical components, insulated cables, etc., can solve the problems of low temperature resistance and elasticity that are difficult to meet the requirements of use at the same time, achieve excellent physical and mechanical properties, broad application prospects, good elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

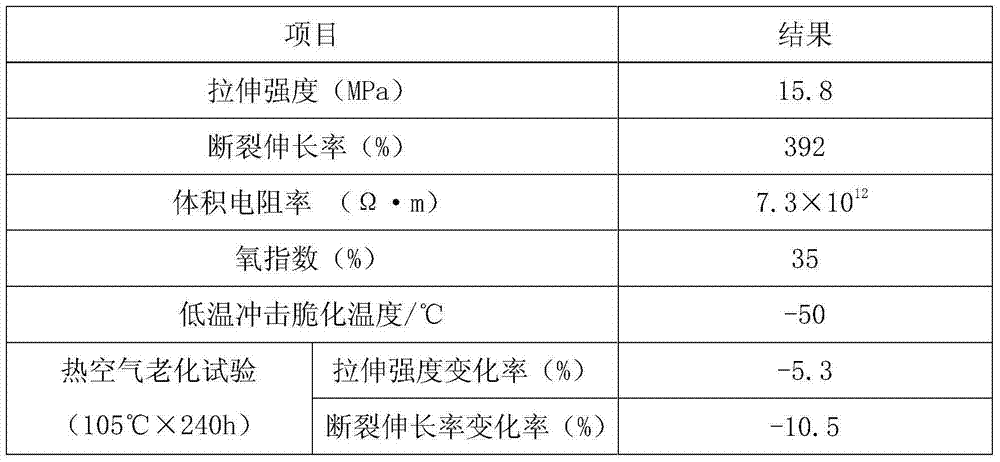

[0012] A low-temperature-resistant high-elastic chlorinated polyethylene power cord sheathing material, made of the following raw materials in weight (kg): chlorinated polyethylene 80, ethylene-vinyl acetate copolymer 20, thermoplastic polyurethane elastomer 10, double-tert-butyl Cumene peroxide 0.5, triallyl isocyanurate 2, molybdenum disulfide 6, antimony trioxide 12, silicon micropowder 10, polytetrafluoroethylene micropowder 7, dioctyl nylon acid 15, Sorbitol 4, dioctyl sebacate 8, precipitated silica 22, accelerator TMTD2, antioxidant ODA1, antioxidant TPPD2, composite filler 4;

[0013] The preparation method of the composite filler is as follows: a. Take the following raw materials by weight (kg): pyrophyllite 10, diopside 8, opalite 6, N-2-(aminoethyl)-3-aminopropyltrimethoxy Silane 1.5, calcium lignosulfonate 2, sodium silicate 4, tourmaline slag 6, nano-diamond 4, germanium stone powder 3, sodium stearate 2; b, calcining pyrophyllite, diopside, and opalite at 580°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com