Liquid silicon resin foam material and preparation method thereof

A technology of resin foam and liquid silicon, applied in the field of organic materials and their preparation, can solve the problems of brittleness and complexity, and achieve the effects of excellent electrical insulation performance, good reinforcement effect and high industrial application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

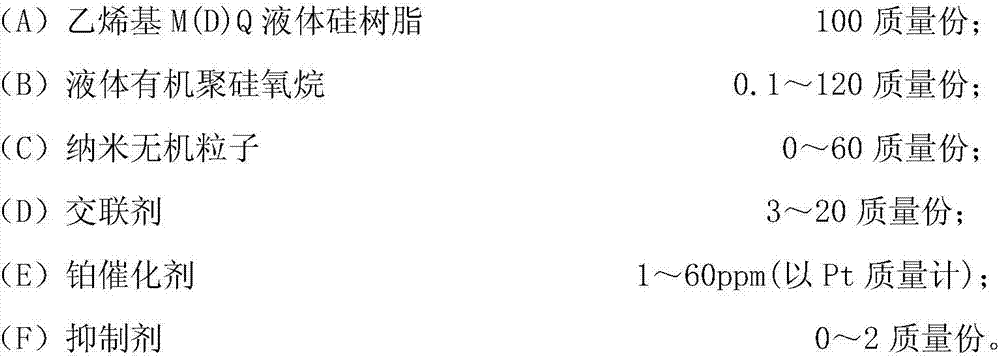

Method used

Image

Examples

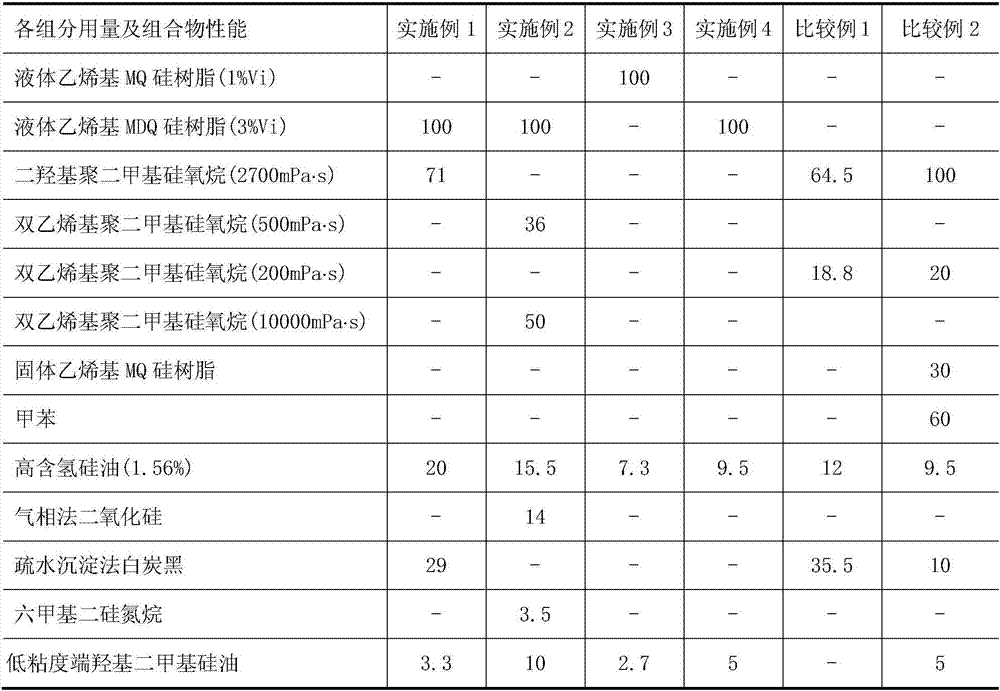

Embodiment 1

[0081] 100 parts by mass of α, ω-dihydroxy polydimethylsiloxane (colorless transparent flowing liquid, viscosity 2000mPa·s, volatile matter 1.0%, manufactured by Shanghai Resin Factory Co., Ltd.), 40 parts of BET specific surface area is 125m 2 Hydrophobic precipitation method silica (manufactured by Jilin Tonghua Shuanglong Chemical Co., Ltd.) of / g, 5 parts by mass have silanol groups at both ends and viscosity is 29mm 2 / s (23°C) of dimethyl polysiloxane, add it to a 5L vacuum kneader, mix it in at room temperature, knead it in vacuum at 130°C for 2 hours, discharge and cool to room temperature to obtain liquid polysiloxane nano particle base.

[0082] With 100 parts by mass of liquid vinyl MDQ silicone resin (vinyl content 3%, MQ value 0.8, viscosity 5000mPa s, manufactured by Shanghai Aishibo Chemical Co., Ltd.), 100 parts by mass of liquid polysiloxane nanoparticle base material (containing α,ω-dihydroxy polydimethylsiloxane about 71 parts by mass, nano-silica particles...

Embodiment 2

[0086] 100 parts by mass of α,ω-bisvinyl polydimethylsiloxane (vinyl content 0.31%, viscosity 500mPa·s, produced by Zhejiang Quzhou Jiancheng Silicone Co., Ltd.), 40 parts by mass of BET specific surface area of 197.5m 2 / g of fumed silica (produced by Shenyang Chemical Co., Ltd.), 5 parts by mass having silanol groups at both ends and a viscosity of 29mm 2 / s (23 ℃) of dimethylpolysiloxane, 5 parts by mass of hexamethyldisilazane (produced by Anhui Bengbu Silicone Chemical Factory, with a purity greater than 98%), added to a 5L vacuum kneader, at room temperature After mixing, vacuum knead at 130° C. for 2 hours, discharge and cool to room temperature to obtain liquid polysiloxane nanoparticle base material.

[0087]100 parts by mass of liquid vinyl MDQ silicone resin (vinyl content 3%, MQ value 0.8, viscosity 5000mPa·s, manufactured by Shanghai Aishibo Chemical Co., Ltd.), 50 parts by mass of the above-mentioned divinyl polydimethylsiloxane Nano-silica mixture (containing...

Embodiment 3

[0090] Liquid vinyl MQ silicone resin (vinyl content 1%, MQ value 0.8, viscosity 5000mPa s, manufactured by Zhejiang Runhe Organic Silicon New Material Co., Ltd.) 100 parts by mass, 2.7 parts by mass hydroxyl silicone oil (produced by Zhonghao Chenguang Chemical Research Institute 209-3, viscosity 15-20mPa·s, hydroxyl content 7-9%), 7.3 parts by mass of liquid hydrogen-containing silicone oil (hydrogen content 1.56%, produced by Zhejiang Quzhou Jiancheng Silicone Co., Ltd.), 0.083 parts by mass of tetramethyl Tetravinylcyclotetrasiloxane (produced by Zhonghao Chenguang Chemical Research Institute, purity not less than 99%) and 0.39 parts by mass of VM-23 platinum catalyst (Pt mass fraction 3000ppm, produced by Zhejiang Quzhou Jiancheng Organic Silicon Co., Ltd.) wherein Pt Catalyst is 11.7ppm in terms of Pt mass, since component (C) is not used, and there is no need to go through the dispersion step of nanoparticles, the above-mentioned components are directly mixed in a beaker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com