Europium and samarium-doped lithium magnesium phosphate photostimulated luminescent material and preparation method thereof

A light-stimulated luminescence, lithium magnesium phosphate technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unsuitable radiation dose test system, unstable material thermoluminescence performance, easy distortion of test signal, etc., and achieve improvement Radiation dose response linear range, the effect of improving photo-stimulated luminescence performance and improving thermoluminescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. In an agate mortar, mix lithium hydroxide: magnesium nitrate: ammonium dihydrogen phosphate: boric acid: europium oxide: samarium oxide=1:0.91:0.87:0.0065:0.0035:0.0030 by molar ratio, grind for 1h, and pack Porcelain crucibles made of alumina are placed in a high-temperature sintering furnace and heated to a temperature of 250-℃ for 2 hours, then heated to a temperature of 500-℃ for 2 hours, and finally at a reaction temperature of 900-℃ for 25 hours. sintering;

[0027] b. After the reaction, cool the alumina crucible to room temperature, take out the raw materials in the crucible, and you can get europium samarium doped lithium magnesium phosphate LiMgPO 4 : Eu, Sm, B light-excited luminescent materials;

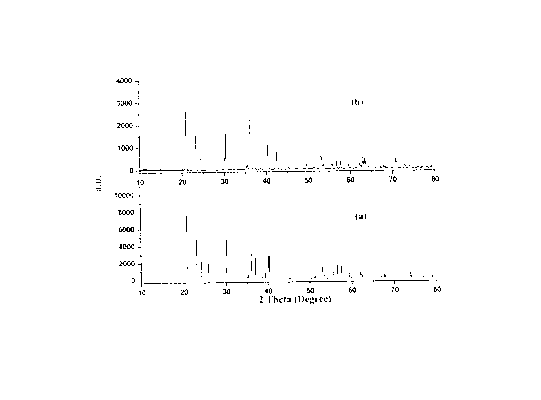

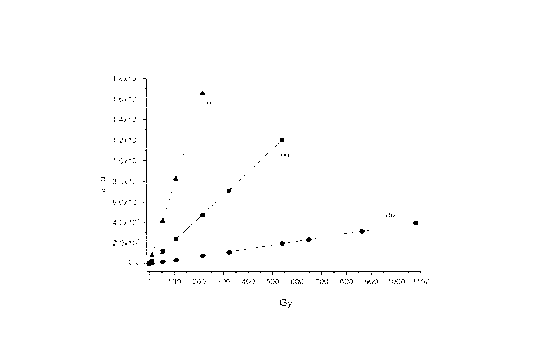

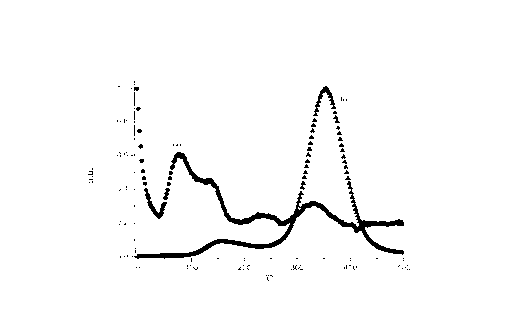

[0028] Test and analyze with TL / OSL-DA-15 optical luminescence / thermoluminescence dual-purpose readout instrument, LiMgPO 4 : Eu, Sm, B radiation dose response linear range is 0.1-300Gy, the sensitivity is LiMgPO 4 : Tb, 3 times of B, the main peak of thermol...

Embodiment 2

[0030] a. In an agate mortar, mix lithium hydroxide: magnesium nitrate: ammonium dihydrogen phosphate: boric acid: europium oxide: samarium oxide = 1:0.91:0.87:0.0073:0.004:0.0038 in molar ratio, grind for 1h, and pack Porcelain crucibles made of alumina are placed in a high-temperature sintering furnace and heated to a temperature of 250-℃ for 2 hours, then heated to a temperature of 500-℃ for 2 hours, and finally the reaction temperature is 950-℃, and the reaction time is 18 hours. sintering;

[0031] b. After the reaction, cool the alumina crucible to room temperature, take out the raw materials in the crucible, and you can get europium samarium doped lithium magnesium phosphate LiMgPO 4 : Eu, Sm, B light-excited luminescent materials;

[0032] Test and analyze with TL / OSL-DA-15 optical luminescence / thermoluminescence dual-purpose readout instrument, LiMgPO 4 : The radiation dose response of Eu, Sm, B is linear in the range of 0.1-400 Gy, and the sensitivity is LiMgPO 4 ...

Embodiment 3

[0034] a. In an agate mortar, mix lithium hydroxide: magnesium nitrate: ammonium dihydrogen phosphate: boric acid: europium oxide: samarium oxide=1:0.91:0.87:0.008:0.0043:0.0047 in molar ratio, grind for 1h, and pack Porcelain crucibles made of alumina are placed in a high-temperature sintering furnace and heated to a temperature of 250-℃ for 2 hours, then heated to a temperature of 500-℃ for 2 hours, and finally at a reaction temperature of 950-℃ for 15 hours. sintering;

[0035] b. After the reaction, cool the alumina crucible to room temperature, take out the raw materials in the crucible, and you can get europium samarium doped lithium magnesium phosphate LiMgPO 4 : Eu, Sm, B light-excited luminescent materials;

[0036] Test and analyze with TL / OSL-DA-15 optical luminescence / thermoluminescence dual-purpose readout instrument and other equipment, LiMgPO 4 : The radiation dose response of Eu, Sm, and B is linear in the range of 0.1-540 Gy, and the sensitivity is LiMgPO 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com