Tin-copper alloy cathode material used for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle performance and low specific capacity, and achieve continuous electroplating, high charge and discharge specific capacity, and reduce electroplating the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

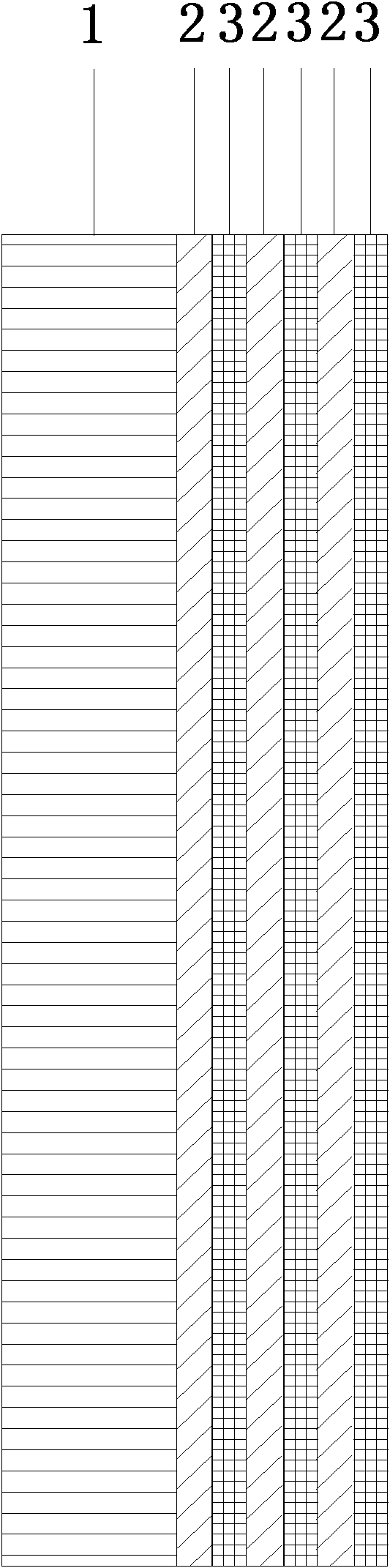

[0047] Copper strip was chosen as the electroplating substrate.

[0048] 1. Pretreatment of copper strip

[0049] Degreasing solution:

[0050] Sodium hydroxide 30g / L

[0051] Sodium carbonate 40g / L

[0052] Sodium Phosphate 30g / L

[0053] Sodium silicate 8g / L

[0054] Degreasing temperature: 80°C

[0055] Activation solution:

[0056] Sulfuric acid: 40g / L

[0057] Activation temperature: room temperature

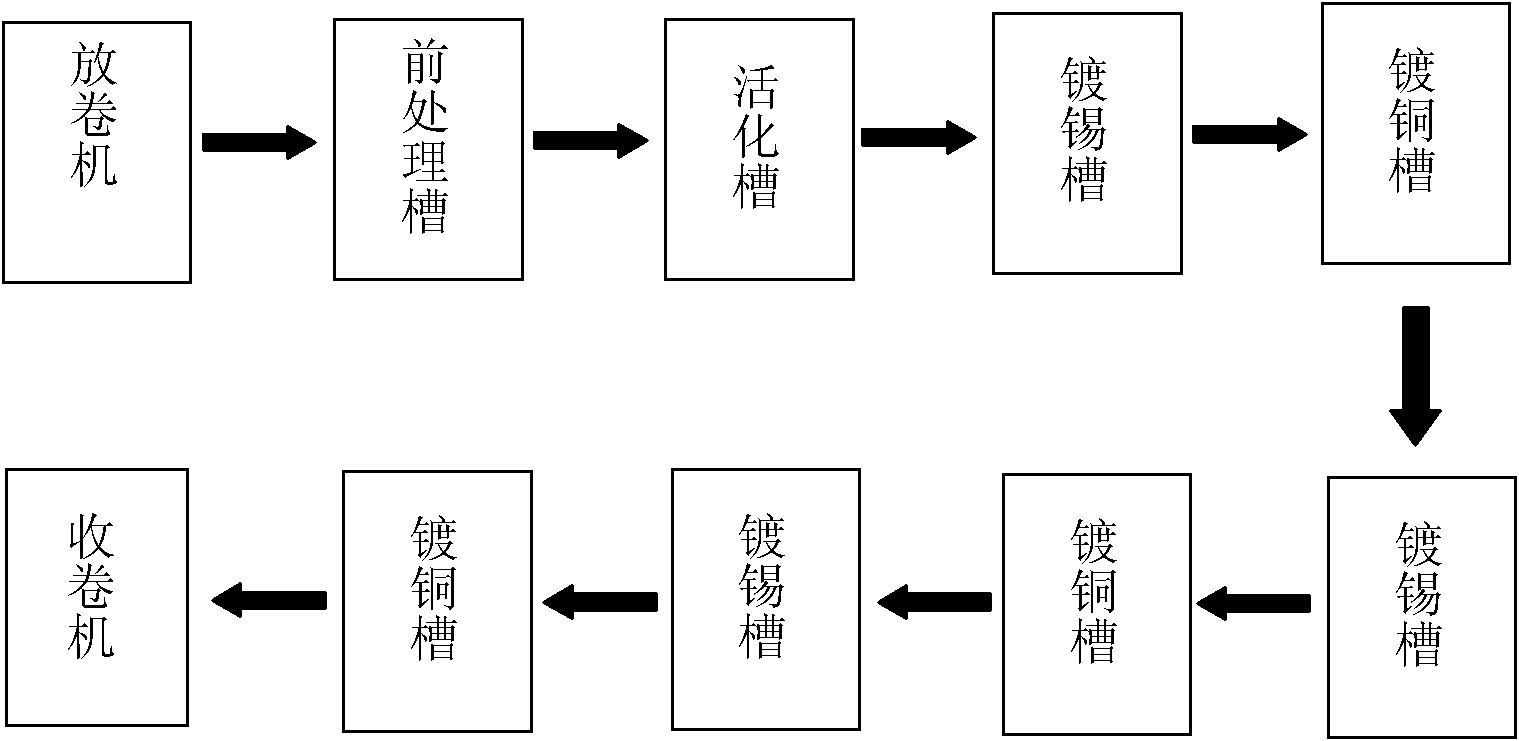

[0058] Pour the pretreatment solution into the pretreatment tank of the continuous electroplating apparatus in sequence, and heat it to the specified temperature.

[0059] 2. Preparation of electroplating solution

[0060] The plating solution formula of the tin plating layer is,

[0061] Sodium stannate 80g / L

[0062] Sodium hydroxide 9g / L

[0063] Hydrogen peroxide 25g / L

[0064] Plating temperature 70°C

[0065] The plating solution formula of electroplating copper layer is,

[0066] Copper pyrophosphate 60g / L

[0067] Potassium pyrophosphate 280g / L

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com