Plasma auxiliary high-energy roller ball mill device

A plasma and roller ball technology, applied in grain processing and other directions, can solve the problems of the interference between the electrode shaft and the roller rotation, the large vibration of the ball mill, and the large impact of the electrode rod. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in detail through the following embodiments and accompanying drawings. However, embodiments of the invention are not limited thereto.

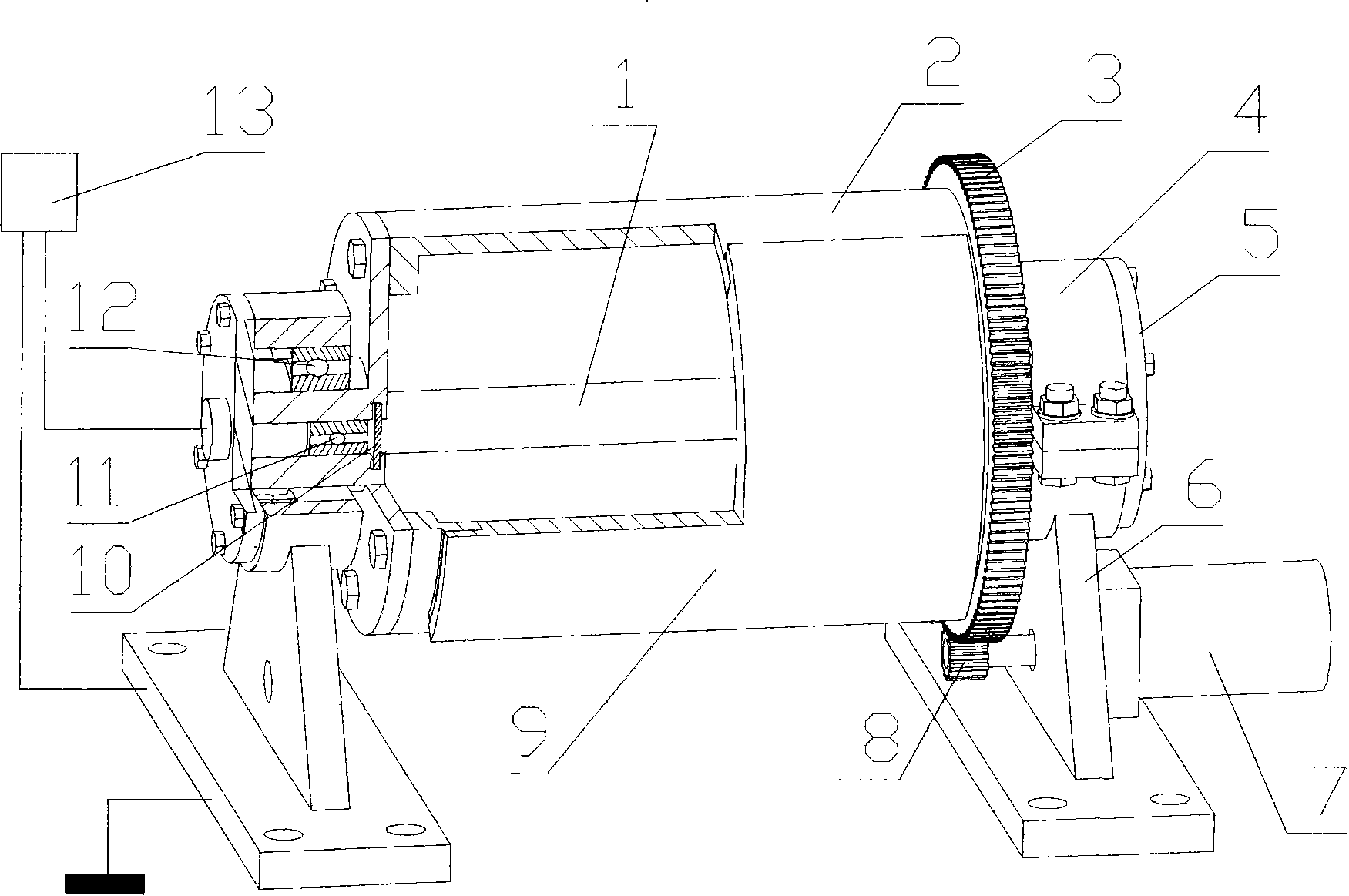

[0015] Such as figure 1 As shown, the plasma-assisted high-energy roller milling device consists of an electrode shaft 1, a roller body 2, a large ring gear 3, a bearing seat upper cover 4, a bearing seat end cover 5, a bearing seat 6, a speed regulating motor 7, a pinion 8, and a roller Body cover 9, sealing ring 10, small bearing 11, large bearing 12, and power supply 13; their connection relationship is as follows: in the center of the traditional roller ball mill, a fixed electrode shaft 1 is installed through the end cover of the bearing seat, and the electrode shaft 1. It is coaxial with the drum body 2 and is movably connected to each other through the small insulating bearing 11. The sealing ring 10 is embedded in the small bearing 11 in the journal hole of the drum body to assemble it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com