Compressed air heat exchange system

A heat exchange system and compressed air technology, applied in compressors, compressors with reversible cycles, lighting and heating equipment, etc., can solve the problems of inability to realize humidification function, environmental hazards, etc., and achieve simple structure and reduce the environment Hazardous, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

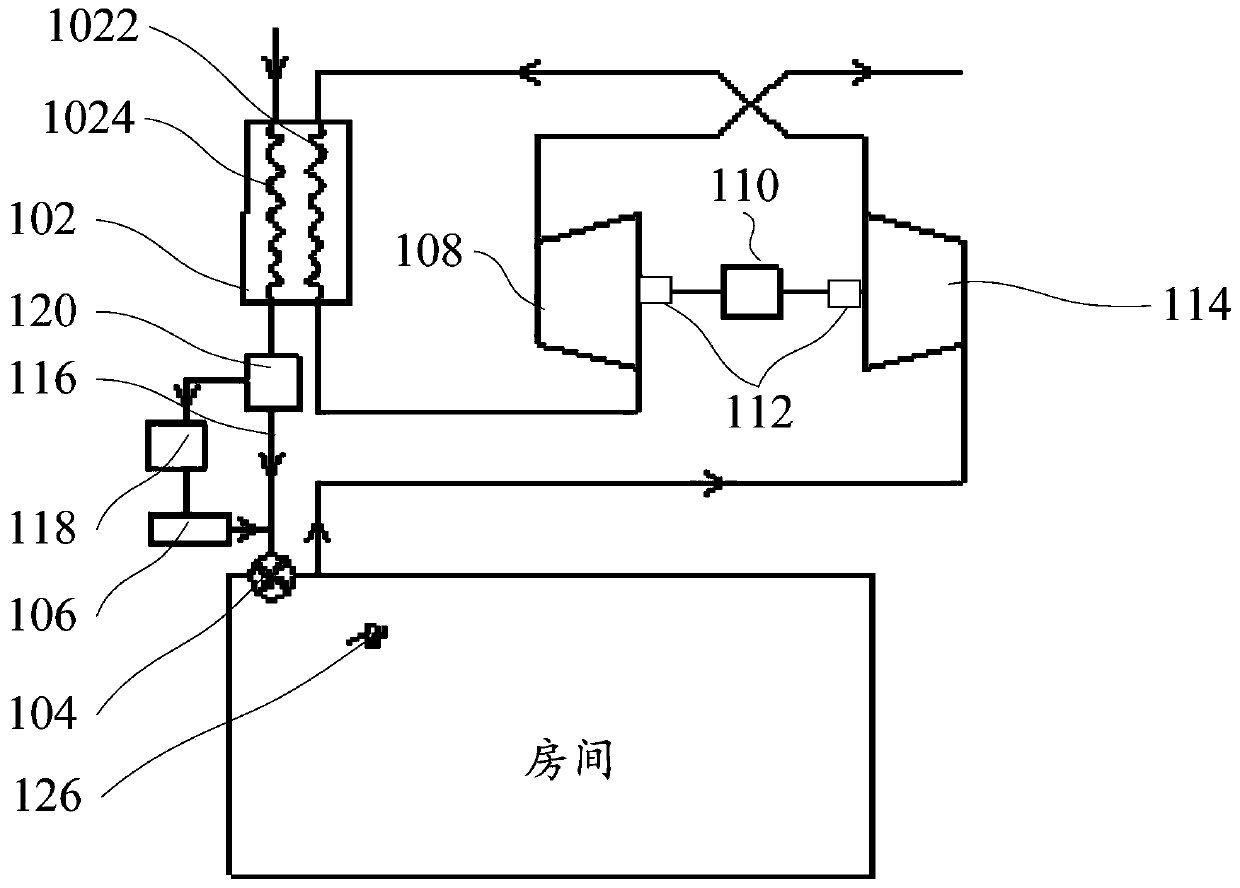

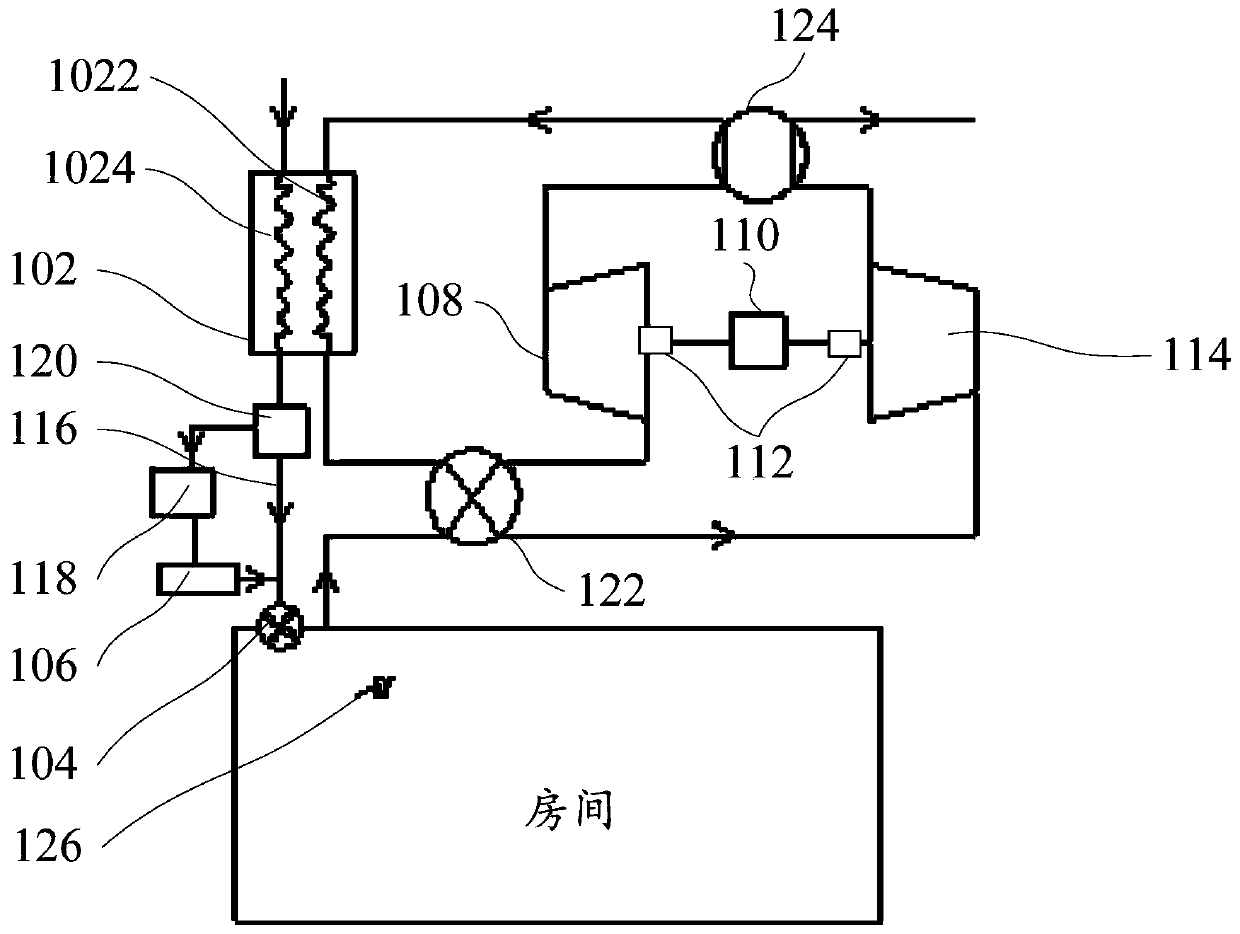

[0053] Such as figure 1 As shown, the compressed air heat exchange system includes: processor (see Figure 6 ), pressurized expansion assembly, heat exchanger 102, fan 104 and humidification module 106.

[0054] Among them, the processor is used to execute computer instructions.

[0055] The heat exchanger 102 is an air-cooled heat exchanger 102, at least including a first flow path 1022 and a second flow path 1024 capable of mutual heat exchange.

[0056] The fan 104 is electrically connected to the processor, and is used to drive outdoor fresh air to flow into the room through the second flow path 1024 .

[0057] The pressurized expansion assembly, the pressurized expansion assembly, is electrically connected to the processor and communicated with the first flow path 1022, and the pressurized expansion assembly is provided with an air return port and an exhaust port.

[0058] The humidification module 106 is electrically connected to the processor, and can communicate wit...

Embodiment 2

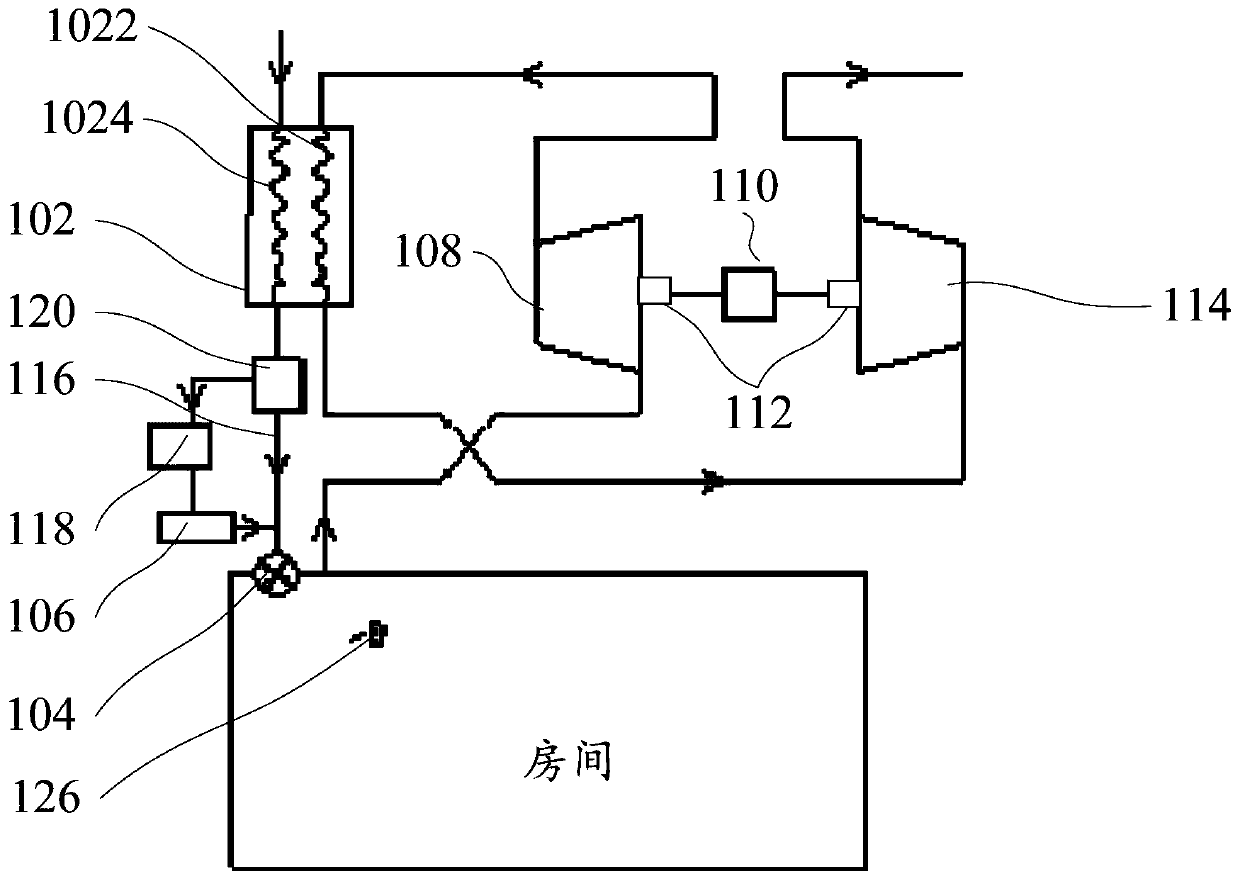

[0071] According to the compressed air heat exchange system of this embodiment, based on different pipeline connection modes, it may only have the functions of heating and humidification.

[0072] Such as figure 2 As shown, in some embodiments, a specific arrangement of the pressurized expansion assembly includes: the expander 108 is provided with an exhaust port and communicated with the outlet of the first flow path 1022, and the compressor 114 is provided with a return air port and connected with the first flow path The inlet of the first flow path 1022 is connected, wherein the indoor air enters the compressor 114 through the air return port to heat up, enters the first flow path 1022 and exchanges heat with the second flow path 1024, and then returns to the expander 108, and the outdoor fresh air in the second flow path 1024 After the temperature rises, it is humidified by the humidification module 106 and enters the room.

[0073] In this embodiment, the air return por...

Embodiment 3

[0075] According to the compressed air heat exchange system of this embodiment, based on different pipeline connection modes, it may only have the functions of cooling and humidification.

[0076] Such as figure 1 As shown, in some embodiments, another specific arrangement of the pressurized expansion assembly, the compressor 114 is provided with an exhaust port, and communicated with the outlet of the first flow path 1022, and the expander 108 is provided with a return air port, and connected with the first flow path The inlet of the path 1022 is connected, wherein the indoor air enters the expander 108 through the air return port to cool down, enters the first flow path 1022 and exchanges heat with the second flow path 1024, and then returns to the compressor 114, and the outdoor fresh air in the second flow path 1024 cools down. Afterwards, it is humidified by the humidification module 106 and enters the room.

[0077]In this embodiment, the air return port is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com