A hard coating composition and hardened film containing the hard coating composition

A composition and hard coating technology, applied in the directions of coatings, layered products, chemical instruments and methods, etc., can solve the problem of poor adhesion between the hard coating and the surface of the substrate, unsatisfactory adhesion of the hard coating composition, electrical Halo bottom layer or glue bottom layer failure and other problems, to achieve the effect of improving adhesion, reducing internal stress, and good spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

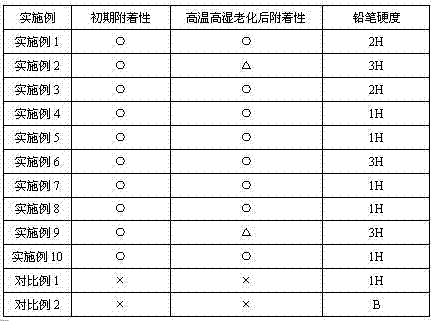

Examples

Embodiment 1

[0046] 21 parts of dipentaerythritol hexaacrylate,

[0047] 9 parts of hydroxyethyl acrylate,

[0048] 3 parts of photoinitiator Irgacure 1173,

[0049] 50 parts of methyl ethyl ketone,

[0050] 20 parts of isopropanol,

[0051] BYK-3500 0.1 copies,

[0052] To 21 parts of dipentaerythritol hexaacrylate resin (manufactured by Nippon Kayaku Co., Ltd.), add 9 parts of hydroxyethyl acrylate monomer (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 3 parts of photoinitiator Irgacure 1173 (manufactured by Nanjing Ji'an Chemical Co., Ltd.) ). Dilute the resulting mixture with a mixed solvent of 50 parts of methyl ethyl ketone and 20 parts of isopropanol, and then add 0.1 parts by weight of the organic silicon wetting aid BYK-3500 (manufactured by BYK Chemicals), stir well to obtain a hard coating composition Things.

[0053] The obtained hard coating composition was coated with a wire rod on one side of a base film with a thickness of 175 microns of polyethylene terephthalate film (m...

Embodiment 2

[0055] 16 parts of pentaerythritol triacrylate,

[0056] 48 parts of dipentaerythritol hexaacrylate,

[0057] 16 parts of 2-phenoxyethyl acrylate,

[0058] 10 parts of photoinitiator Irgacure 1173,

[0059] 4 parts of phenol,

[0060] 16 parts of ethyl acetate,

[0061] BYK-3700 5 copies,

[0062] To 48 parts of dipentaerythritol hexaacrylate (manufactured by Nippon Kayaku Co., Ltd.) and 16 parts of pentaerythritol triacrylate (manufactured by Tianjin Tianjiao Chemical Industry), 16 parts of 2-phenoxyethyl acrylate monomer (manufactured by Sartomer Chemical Industry) were added , Add 8 parts of photoinitiator Irgacure 1173 (manufactured by Nanjing Ji'an Chemical Co., Ltd.). The obtained mixture was diluted with a mixed solvent of 16 parts of ethyl acetate and 4 parts of phenol, and then 5 parts of organic silicon wetting aid BYK-3500 (manufactured by BYK Chemicals) was added, and the mixture was stirred well to obtain a hard coating composition.

[0063] The obtained hard coating composi...

Embodiment 3

[0065] 15 parts of pentaerythritol triacrylate,

[0066] 9 parts of trimethylolpropane triacrylate,

[0067] 6 parts of isobornyl acrylate,

[0068] 1 part of photoinitiator Irgacure 1173,

[0069] 16 parts of phenol,

[0070] 40 parts of ethanol,

[0071] 14 parts of butyl acetate,

[0072] BYK-3500 0.2 copies,

[0073] To 15 parts of pentaerythritol triacrylate (manufactured by Tianjin Tianjiao Chemical) and 9 parts of trimethylolpropane triacrylate (manufactured by Nippon Kayaku Co., Ltd.), add 6 parts of isobornyl acrylate (manufactured by Sartomer Chemical), and add 1 Photoinitiator Irgacure 1173 (manufactured by Nanjing Ji'an Chemical Co., Ltd.). Dilute the resulting mixture with a mixed solvent of 16 parts of phenol, 40 parts of ethanol and 14 parts of butyl acetate, and then add 0.2 parts of organic silicon wetting aid BYK-3500 (manufactured by BYK Chemicals), stir well to obtain a hard coat Layer composition.

[0074] The obtained hard coating composition was coated with a wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com