Special material regulating angle valve for high-pressure hydrogenation reaction

A high-pressure hydrogenation and angle adjustment technology, which is applied in the field of angle adjustment valves, can solve problems affecting the flow capacity of valves and erosion of adjustment valves, and achieve the effects of prolonging service life, ensuring smooth flow, and reducing output thrust requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

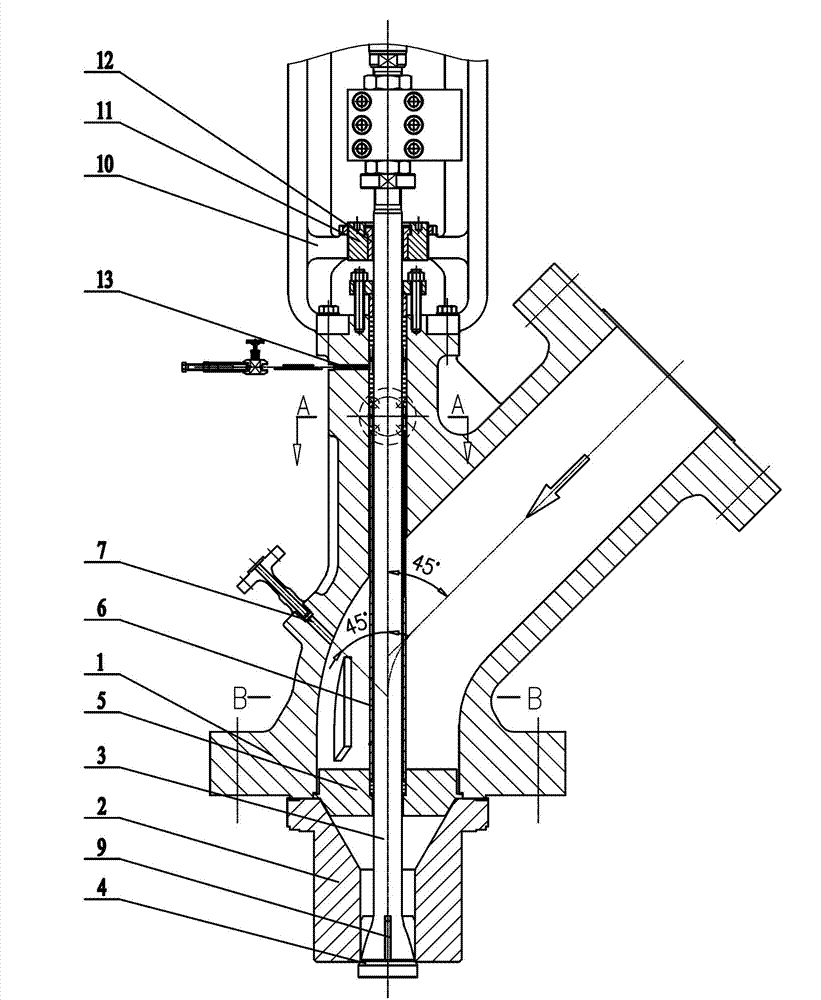

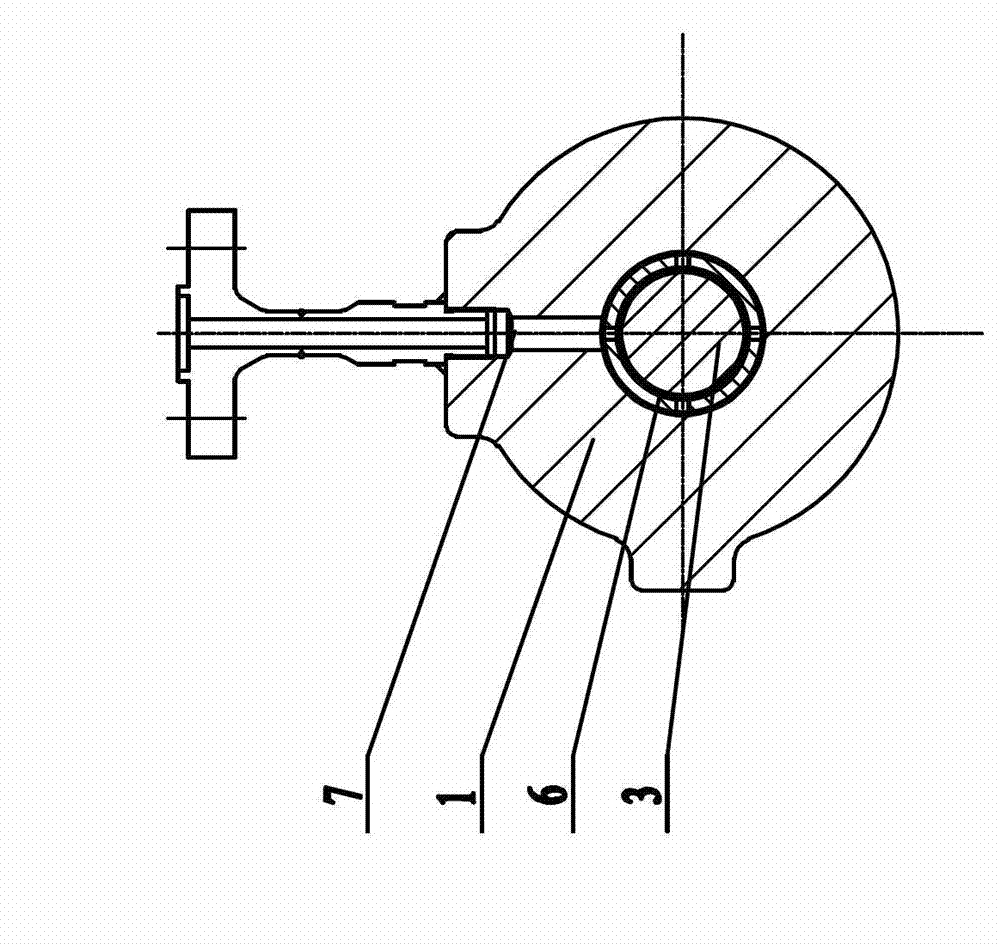

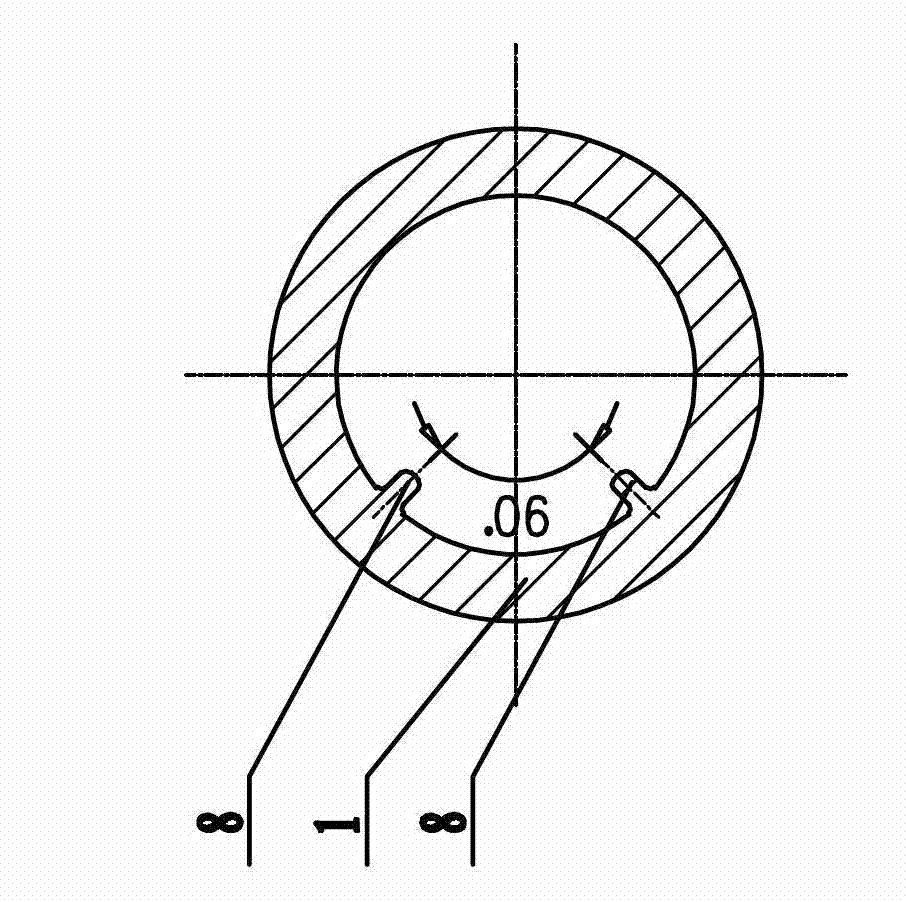

[0026] As shown in the figure, the high-pressure hydrogenation reaction special material regulating angle valve includes a valve body 1, a valve seat 2, a valve stem 3 and a valve core 4. The valve seat 2 is fixed on the valve body 1 and slides in the valve body 1. The valve stem 3 is plugged tightly, and the valve core 4 is integrally connected to the bottom end of the valve stem 3. An auxiliary guide seat 5 is installed between the valve body 1 and the valve seat 2, and the auxiliary guide seat 5 An anti-scour sleeve 6 is installed on the top, one end of the anti-scour sleeve 6 is embedded in the auxiliary guide seat 5, the other end of the anti-scour sleeve 6 is embedded in the valve body 1, and the valve stem 3 is slidably inserted into the anti-scour sleeve. Inside tube 6.

[0027] There are two flushing ports 7 on the outside of the valve body, one flushing port 7 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com