Boiler water-cooled wall protecting device capable of preventing coking and high temperature corrosion

A protection device and anti-high temperature technology, which is applied in the field of low nitrogen emission of boilers, can solve the problems of impingement on the water wall, deflection of airflow, coking of the water wall, etc., and achieve the effects of enhancing disturbance, improving combustion efficiency, and reducing nitrogen oxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

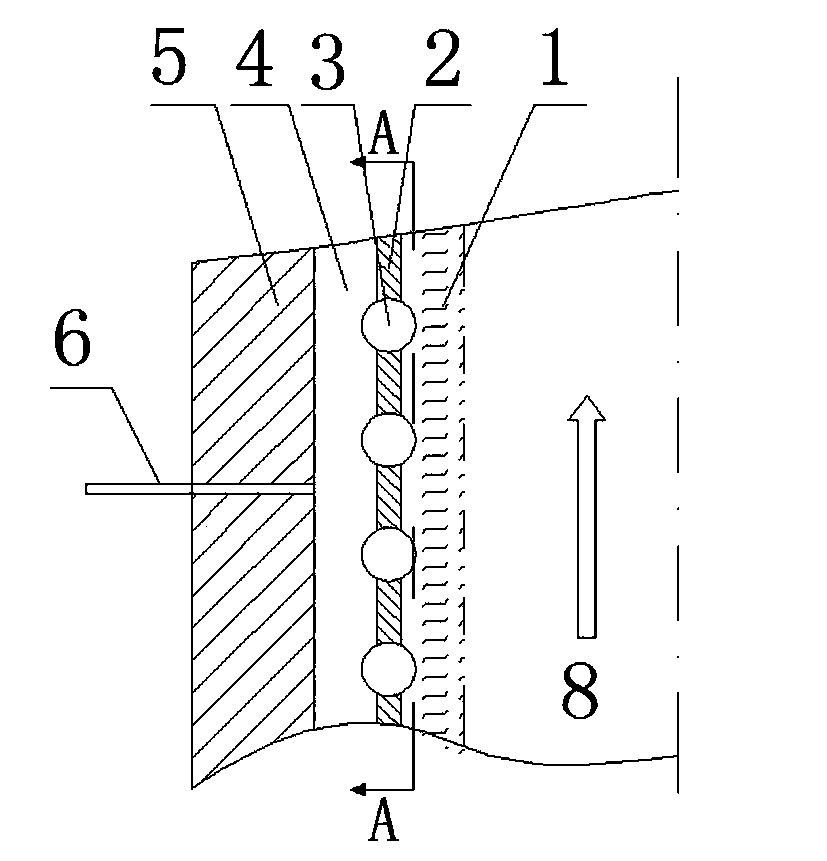

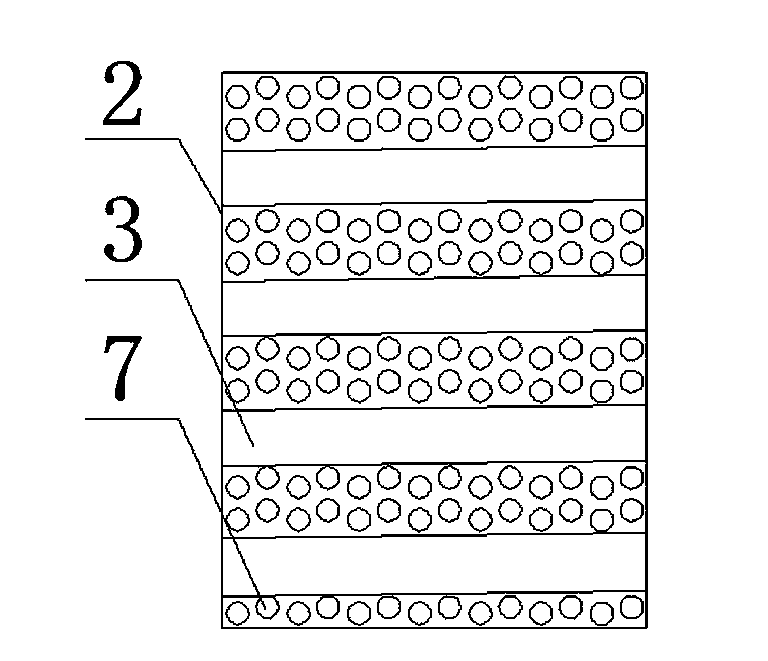

[0013] Such as figure 1 As shown, it is realized in the present invention that small holes 7 are evenly opened on the flat steel 2, and the flat steel 2 and the water-cooled pipe 3 are alternately welded together to form a "membrane water-cooled wall". The membrane water cooling wall and the heat preservation furnace wall 5 are separated by an appropriate distance to form an annular cavity 4 . The air pipeline 6 is installed on the heat preservation furnace 5 and communicates with the cavity 4 .

[0014] The specific working process of the present invention is as follows: air enters continuously through the air pipeline 6 and fills the cavity 4, the flat steel 2 and the water-cooled tube 3 with small holes 7 evenly opened are welded to form a film-type water-cooled wall, and the air in the cavity 4 passes through. Through the small hole 7, a layer of air film 1 is formed on the surface of the membrane water cooling wall to prevent the pulverized coal flow 8 from directly wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com