Sintering machine

A technology of sintering machine and sintering trolley, which is applied in the direction of furnace type, furnace control device, furnace, etc., and can solve the problems such as the difference in shape, size and density of sintering raw material particles, difficulty in regulating the distribution of solid fuel particles, and narrow adjustable range , to achieve the effects of improving sintering quality, improving heat deficiency, and realizing segregation distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

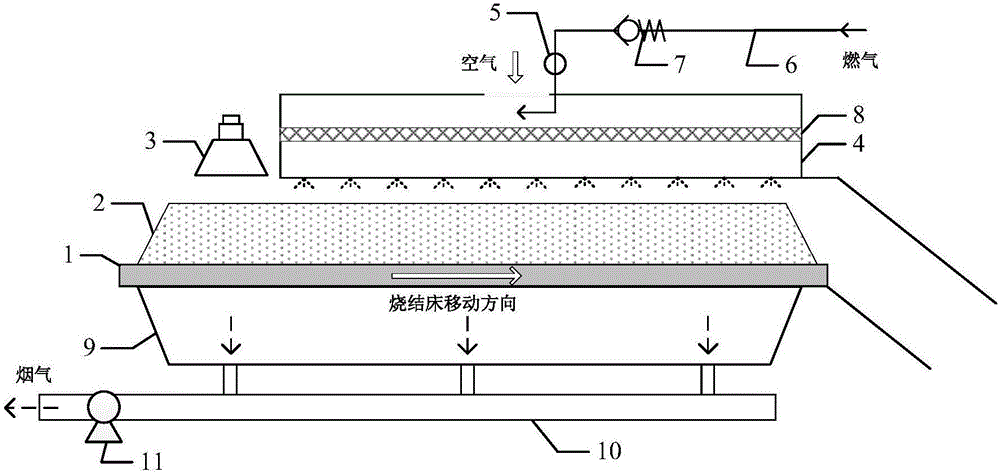

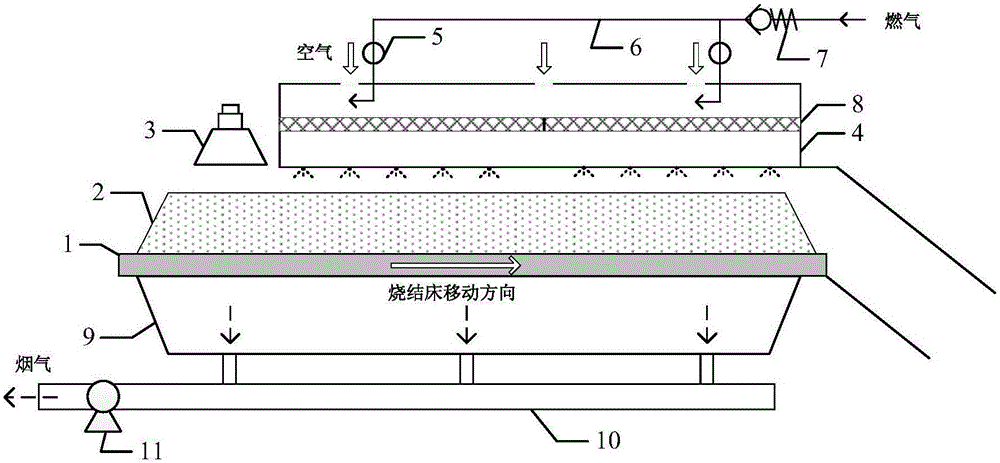

[0021] figure 1 It is a structural schematic diagram of the sintering machine provided by the present invention.

[0022] The sintering machine uses gas and solid fuel to provide heat for the sintering process, and a set of gas injection controller 5 is provided. The sintering raw material 2 moves with the sintering trolley 1, and an air inlet is set on the top of the windshield 4 above the bed of the sintering raw material 2; the gas enters the inside of the top of the windshield 4 from the gas pipeline 6 to mix with air, and the gas injection controller 5 Adjust the gas flow according to the real-time air flow to realize the control of the premixed gas / air concentration. When the sintering raw material 2 on the sintering trolley 1 passes through the igniter 3, the premixed gas / air enters the bed of the sintering raw material 2 under the action of the exhaust fan 11, and is heated and burned above the solid fuel combustion area to form secondary combustion Zone, continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com