Equipment and method for removing nonmetallic slag inclusion in steel and iron smelting process

A metal clip and non-metal technology, used in equipment for removing non-metallic slag inclusions in the process of smelting steel, in the field of high cleanliness steel, it can solve the problems of low work efficiency, small centrifugal force, limited speed, etc., to improve smelting efficiency and quality, improve adsorption effect, good centrifugal effect

Inactive Publication Date: 2011-06-15

冯顺新

View PDF12 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this existing method can rotate and float the non-metallic slag for separation, it takes a certain time for the centrifugation and floating of the larger slag to be separated in time, and it cannot be metallurgically reacted with the cleaning slag in time. and chemical reaction, which affects the adsorption of non-metallic slag inclusions on the cleaning slag and affects the effect of slag removal; because the electromagnetic centrifuge bucket of the prior art is the molten steel in the bucket rotating, due to the huge weight of the molten steel, during the rotation, the speed Limited, the centrifugal force on the center of the molten steel is small, far from achieving the expected centrifugal effect, and in the centrifugation process of molten steel, in order to avoid leakage accidents, molten steel cannot enter and exit during electromagnetic energization, continuous operation cannot be achieved, and work efficiency is low , the production volume is far from meeting the actual demand

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

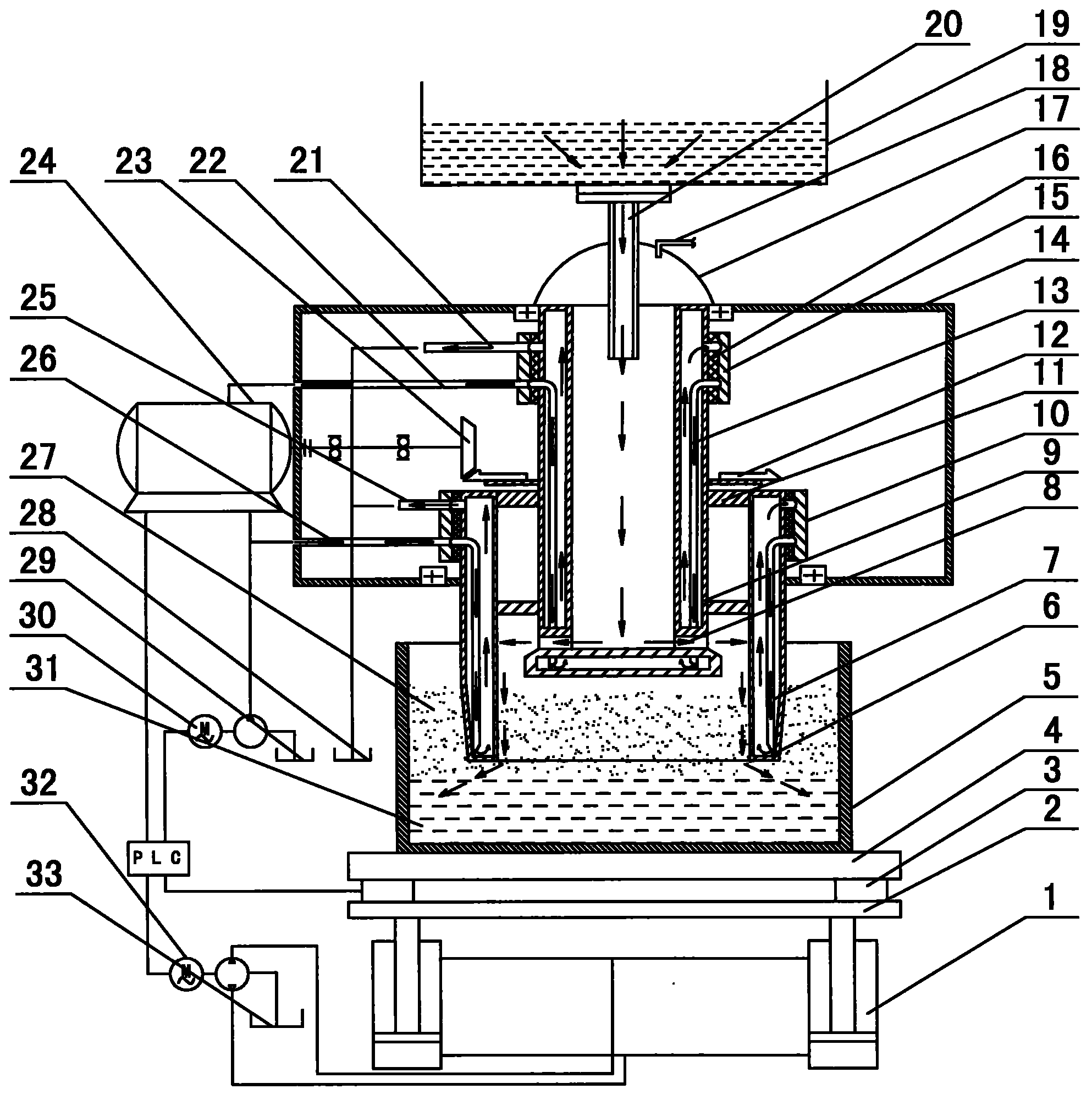

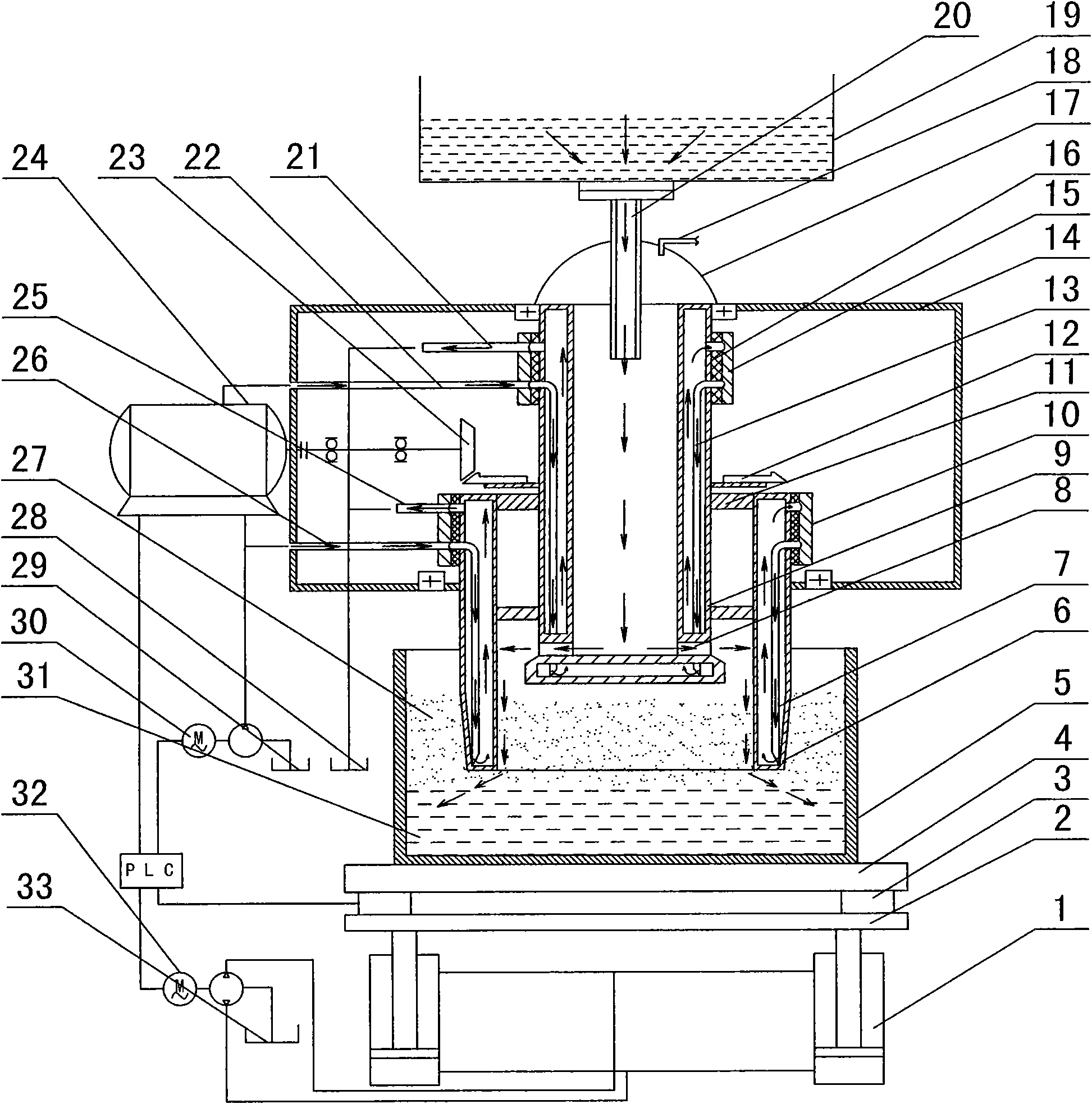

The invention discloses equipment for removing nonmetallic slag inclusion in a steel and iron smelting process. The equipment comprises a primary centrifugal barrel communicated with a tundish, and also comprises a box body, a secondary centrifugal barrel, a ladle and a hydraulic lifting device. A method for removing the nonmetallic slag inclusion by using the equipment comprises that: the nonmetallic slag inclusion is adsorbed through cleaning slag by two times of centrifuging and cleaned, and the passing cleaning slag is accumulated at the bottom of the ladle, so that high-cleanliness molten steel is obtained. Compared with the traditional technology, the equipment and the method overcome the defect that the slag inclusion of big granules cannot be timely adsorbed by the cleaning slag in a process of removing the nonmetallic slag inclusion in the electromagnetic driving centrifugal rotating tundish technology, improve the adsorption effect, and ensure high cleanliness of the centrifuged molten steel; and the nonmetallic slag inclusion is timely adsorbed by the cleaning slag in a two-stage centrifuging mode after the molten steel is subjected to two-time centrifugation, the working process is continuous, the centrifuging effect is good, the smelting efficiency and the quality of the high-cleanliness steel are greatly improved, and the production quantity of the high-cleanliness steel is improved.

Description

Equipment and method for removing non-metallic slag inclusions during iron and steel smelting technical field The invention relates to the field of iron and steel metallurgy, in particular to equipment and a method for removing non-metallic slag inclusions in the process of iron and steel smelting, so as to obtain high cleanliness steel. Background technique In the field of metallurgical technology, in order to remove non-metallic slag inclusions in molten steel during the production of high-cleanness steel, the existing technology is a first-stage centrifugal technology that uses electromagnetically driven rotating centrifugal tundish. The working principle of this technology is: Use electromagnetic drive to rotate the molten steel in the ladle, use the centrifugal force generated by the rotating molten steel to promote the aggregation of non-metallic slag inclusions with a density lower than steel to the center, so that small non-metallic slag inclusions form larger parti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22D43/00C21C7/00

Inventor 冯顺新冯松

Owner 冯顺新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com