Casting method of aluminum alloy cast rod

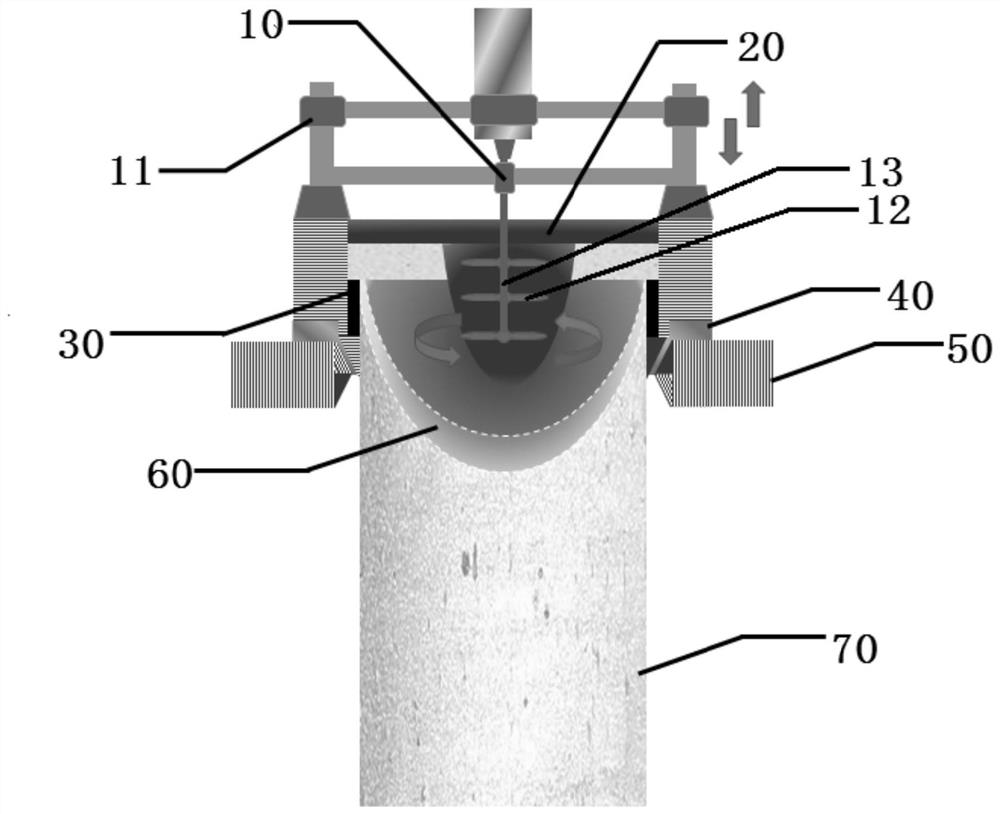

A technology for aluminum alloy and aluminum alloy melt, which is applied in the field of metal smelting and can solve the problems of uneven temperature of aluminum alloy melt, different cooling rates and degrees of cooling, and cracks in cast rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for casting an aluminum alloy cast rod, comprising the following steps:

[0052] The ingredients are calculated according to the mass percentage of the aluminum alloy cast rod element composition: Zn 0.8%, Mn 1.3%, Fe0.1%, Mg 1.8%, Zr 1.0%, the balance is Al and unavoidable impurities, and unavoidable The total mass percentage of impurities is less than 0.15%, and the mass percentage of individual unavoidable impurities is less than 0.05%.

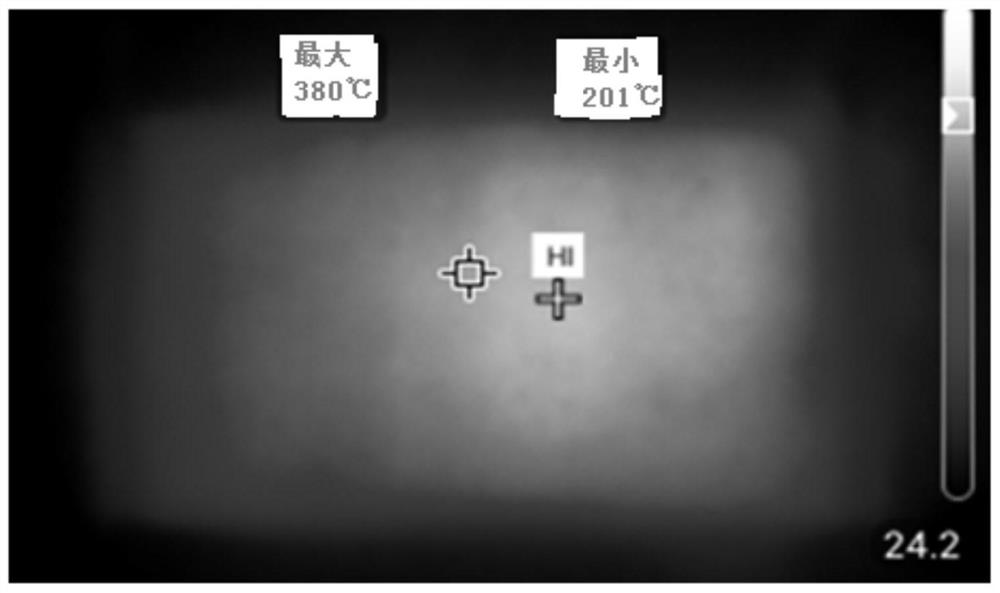

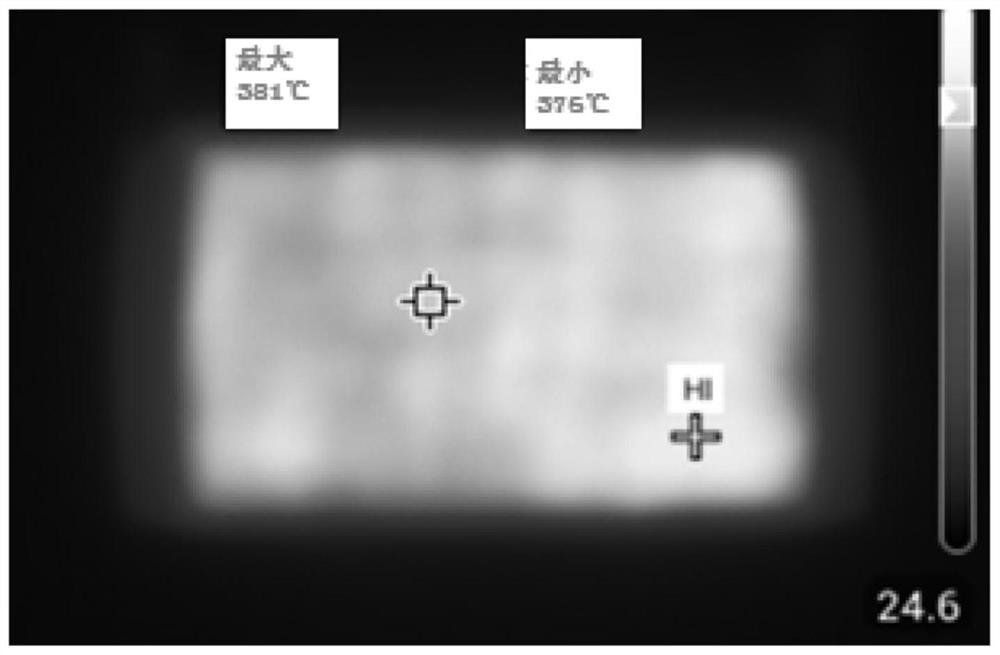

[0053] Put aluminum ingots and copper ingots in a reverberatory furnace, melt and heat up to 750°C, add zinc ingots, aluminum-manganese alloys, aluminum-iron alloys, aluminum-magnesium alloys, and aluminum-zirconium alloys as intermediate alloy materials. After electromagnetic stirring for 15 minutes, use a purity of 99.999%. For the above refining with nitrogen spraying, the refining agent is Al with an amount of 1kg / t for the first refining for 10 minutes, sampling and analyzing the chemical composition, and feeding and f...

Embodiment 2

[0057] A method for casting an aluminum alloy cast rod, comprising the following steps:

[0058] The ingredients are calculated according to the mass percentage of the aluminum alloy cast rod element composition: Zn 0.8%, Mn 1.9%, Fe0.5%, Mg 2.4%, Zr 1.8%, the balance is Al and unavoidable impurities, and unavoidable The total mass percentage of impurities is less than 0.15%, and the mass percentage of individual unavoidable impurities is less than 0.05%.

[0059] Put aluminum ingots and copper ingots in a reverberatory furnace, melt and heat up to 800°C, add zinc ingots, aluminum-manganese alloys, aluminum-iron alloys, aluminum-magnesium alloys and aluminum-zirconium alloys as intermediate alloy materials, and after electromagnetic stirring for 15 minutes, use a purity of 99.999% For the above refining with nitrogen powder spraying, the refining agent is Al with an amount of 2kg / t for the first refining for 25 minutes, sampling and analysis of chemical components, feeding and...

Embodiment 3

[0063] A method for casting an aluminum alloy cast rod, comprising the following steps:

[0064] According to the mass percentage of the aluminum alloy casting rod element components, the ingredients are: Zn0.5%, Mn1.5%, Fe0.3%, Mg2.0%, Zr1.5%, the balance is Al and unavoidable impurities, and The total mass percentage of unavoidable impurities is less than 0.15%, and the mass percentage of a single unavoidable impurity is less than 0.05%.

[0065] Put aluminum ingots and copper ingots in a reverberatory furnace, melt and heat up to 780°C, add zinc ingots, aluminum-manganese alloys, aluminum-iron alloys, aluminum-magnesium alloys, and aluminum-zirconium alloys as intermediate alloy materials. After electromagnetic stirring for 25 minutes, use a purity of 99.999%. For the above refining with nitrogen spraying, the refining agent is Al with an amount of 1.5kg / t for the first refining for 20 minutes, sampling and analyzing the chemical composition, and feeding and feeding refinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com