Molten copper smelting up-drawing process for controlling copper alloy inclusions

A technology for copper alloys and inclusions, which is applied in the field of copper water smelting and extraction process, can solve the problems of unfavorable oxidation inclusions floating and adsorbing, affecting the quality of finished copper rods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

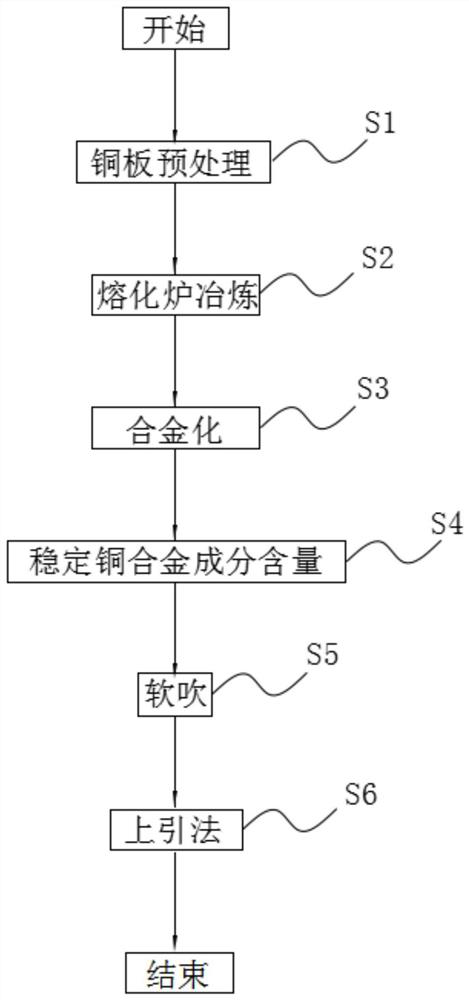

Image

Examples

Embodiment 1

[0037] A copper water smelting upward induction process for controlling copper alloy inclusions, comprising the following steps:

[0038] (1) Copper plate pretreatment: clean up impurities such as patina and copper beans on the surface of the copper plate, then polish and dry the surface of the copper plate;

[0039] (2) Melting furnace smelting: put the pretreated copper plate in the melting furnace to smelt copper water, add a covering agent to the copper water liquid surface in the melting furnace when smelting copper water, the added covering agent can play a role in deoxidation reduction, The role of adsorption inclusions and thermal insulation;

[0040] (3) Alloying: adding alloying elements accounting for 0.06% of the total weight of the copper water to the above-mentioned copper water for alloying, in the alloying process, the copper water is subjected to ultrasonic oscillation treatment, and the ultrasonic oscillation is carried out in three times, and each ultrasonic...

Embodiment 2

[0045] A copper water smelting upward induction process for controlling copper alloy inclusions, comprising the following steps:

[0046] (1) Copper plate pretreatment: clean up impurities such as patina and copper beans on the surface of the copper plate, then polish and dry the surface of the copper plate;

[0047] (2) Melting furnace smelting: put the pretreated copper plate in the melting furnace to smelt copper water, add a covering agent to the copper water liquid surface in the melting furnace when smelting copper water, the added covering agent can play a role in deoxidation reduction, The role of adsorption inclusions and thermal insulation;

[0048] (3) Alloying: adding alloying elements accounting for 0.08% of the total weight of the copper water to the above-mentioned copper water for alloying, in the alloying process, the copper water is subjected to ultrasonic oscillation treatment, and the ultrasonic oscillation is divided into three times, and each ultrasonic o...

Embodiment 3

[0053] A copper water smelting upward induction process for controlling copper alloy inclusions, comprising the following steps:

[0054] (1) Copper plate pretreatment: clean up impurities such as patina and copper beans on the surface of the copper plate, then polish and dry the surface of the copper plate;

[0055] (2) Melting furnace smelting: put the pretreated copper plate in the melting furnace to smelt copper water, add a covering agent to the copper water liquid surface in the melting furnace when smelting copper water, the added covering agent can play a role in deoxidation reduction, The role of adsorption inclusions and thermal insulation;

[0056] (3) Alloying: adding alloying elements accounting for 0.10% of the total weight of the copper water to the above-mentioned copper water for alloying, in the alloying process, the copper water is subjected to ultrasonic oscillation treatment, and the ultrasonic oscillation is carried out in three times, and each ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com