Airtight negative pressure electric arc smelting furnace

A smelting furnace and negative pressure technology, applied in the direction of lighting and heating equipment, can solve the problems of increased difficulty in heat recovery, poor airtightness, and low height of the flue gas hood, so as to reduce heat loss, enhance airtight performance, and avoid Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

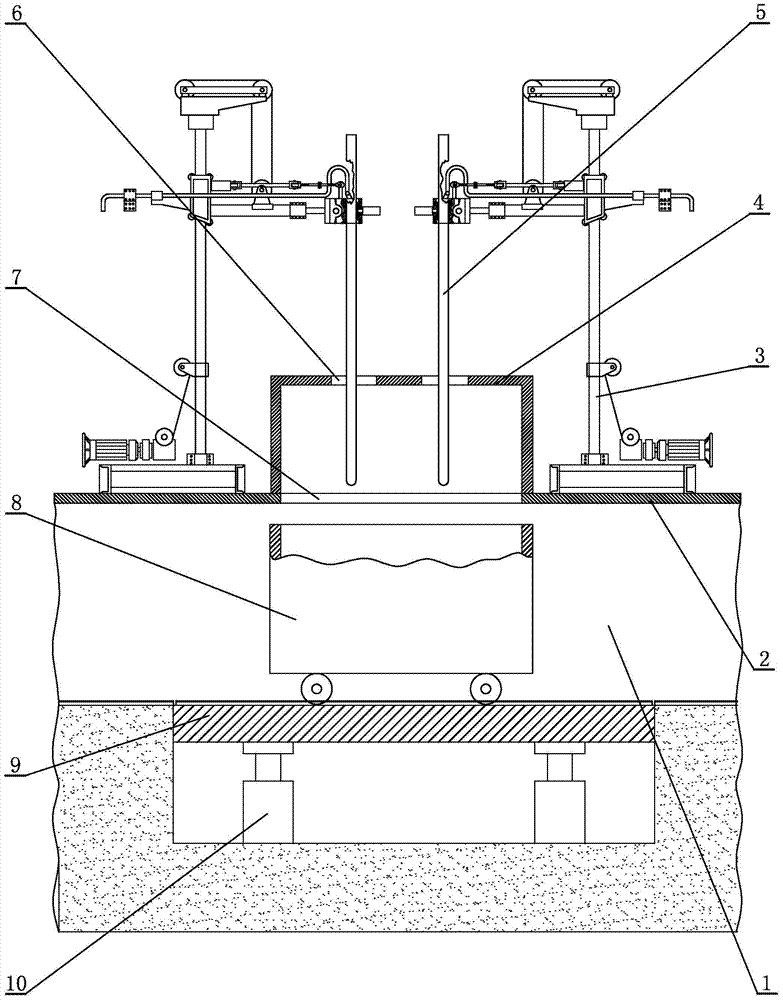

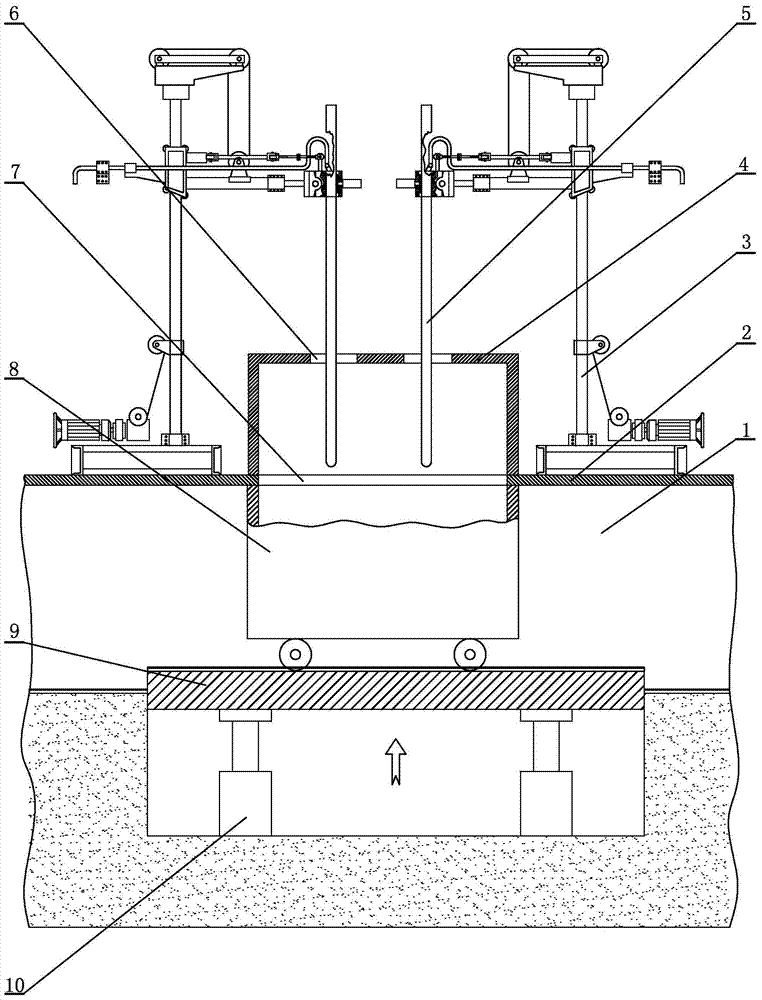

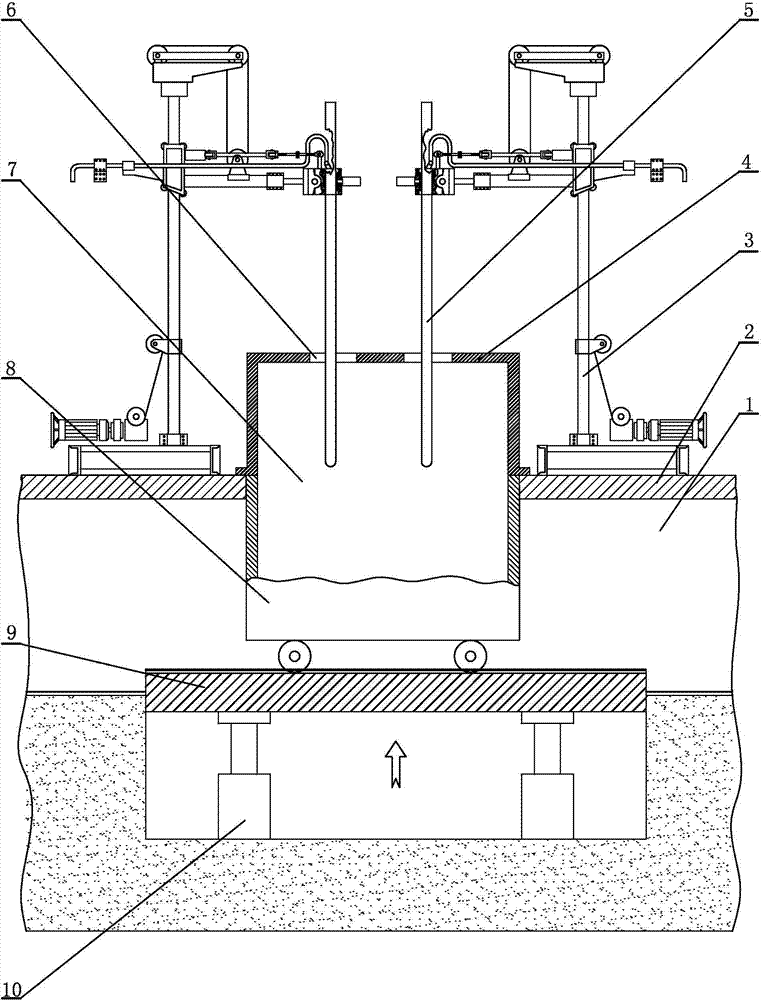

[0029] The general idea of the present invention is to take three measures for the three shortcomings of the existing electric arc smelting furnace, set up a lifting platform, the furnace body can be sealed with the abutment when it rises, and the furnace body can be moved when it is lowered; Increase the height of the fume hood without affecting the electrode action to achieve cooling and airtightness of the fume hood; the column of the electrode frame can swing, the bundled electrodes can be tilted synchronously, and the electrode spacing can be adjusted accurately to obtain the best smelting arc. There can be multiple implementations around this concept, and only four examples are listed below:

[0030] The first embodiment: as figure 1 As shown, this electric arc smelting furnace also has a vertical circular furnace body 8, and the following of the furnace body 8 is provided with traveling wheels, which can move along the track in the channel 1 inside. A base 2 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com