High-silicon molten iron smelting method

A smelting method and molten iron technology, applied in the manufacture of converters, etc., can solve problems such as difficult to control process splashing, large consumption of steel materials, and high silicon content in molten iron, so as to reduce production costs and equipment maintenance costs, increase output, Realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0037] The method for smelting high-silicon molten iron disclosed by the invention comprises the following steps:

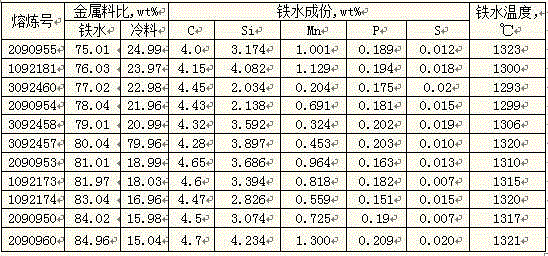

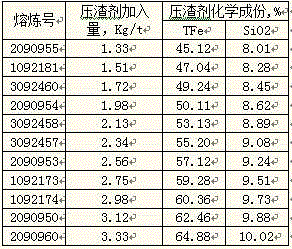

[0038] a. Top-bottom compound smelting is adopted, and the weight percentage of the raw material composition of the metal main material is 75-85% of high-silicon molten iron, and the balance is light steel scrap;

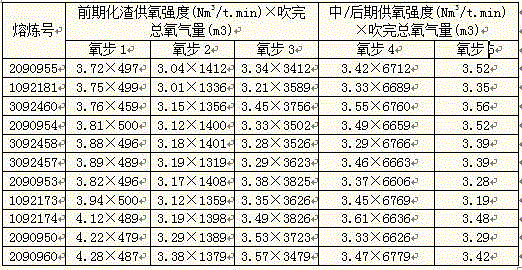

[0039] b. Oxygen control in the early stage of smelting: the oxygen supply intensity of the first 1 / 15 of the oxygen after blowing is 3.7-4.3Nm 3 / t min; Oxygen supply intensity during slag removal period is 3.0-3.4 Nm 3 / t min; the oxygen supply intensity at the end of blowing is 3.2-3.6 Nm 3 / t min;

[0040] C, after blowing down gun in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com