Protective tube for molten steel tapping process

A technology for steel tapping process and protection pipe, which is applied in the field of iron and steel metallurgy and steelmaking, which can solve the problems such as difficult to realize the protection of molten steel, achieve good heat preservation effect, reduce the temperature of steel tapping, and avoid the effect of direct erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

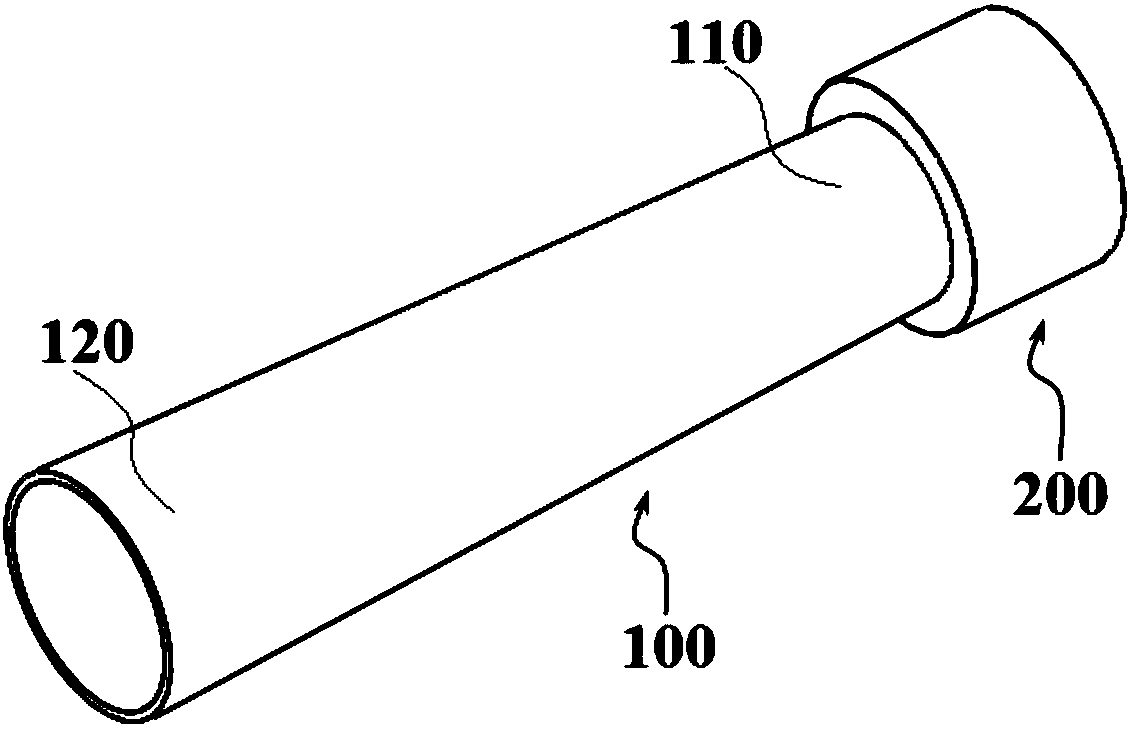

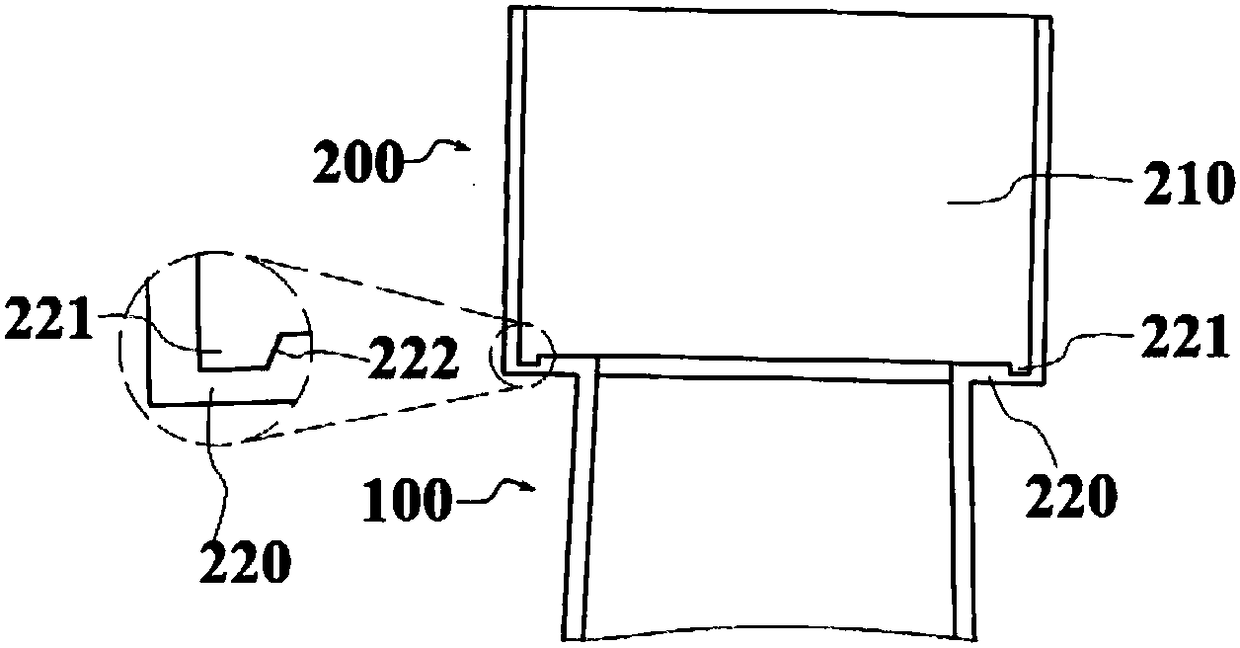

[0045] combine figure 1 As shown, a protective tube used in the process of molten steel tapping of the present invention includes a protective sleeve 100 and a connecting member 200. The inner diameter of the protective sleeve 100 is larger than the diameter of the tapping port, so that the steel flow flows through There is a gap between the protective sleeve 100 and the inner wall of the protective sleeve 100; the connecting member 200 is used to connect with the steel tapping port, and the connecting member 200 is provided with an accommodating cavity 210, and the accommodating cavity 210 is used to be sleeved on the steel tapping port the exterior. Moreover, the accommodating cavity 210 is a cylindrical cavity, and the inner diameter of the cylindrical cavity is larger than the inner diameter of the inlet end 110 of the sleeve.

[0046] The casing inlet end 110 of the protective casing 100 in this embodiment is connected with the connecting member 200 to form a through pro...

Embodiment 2

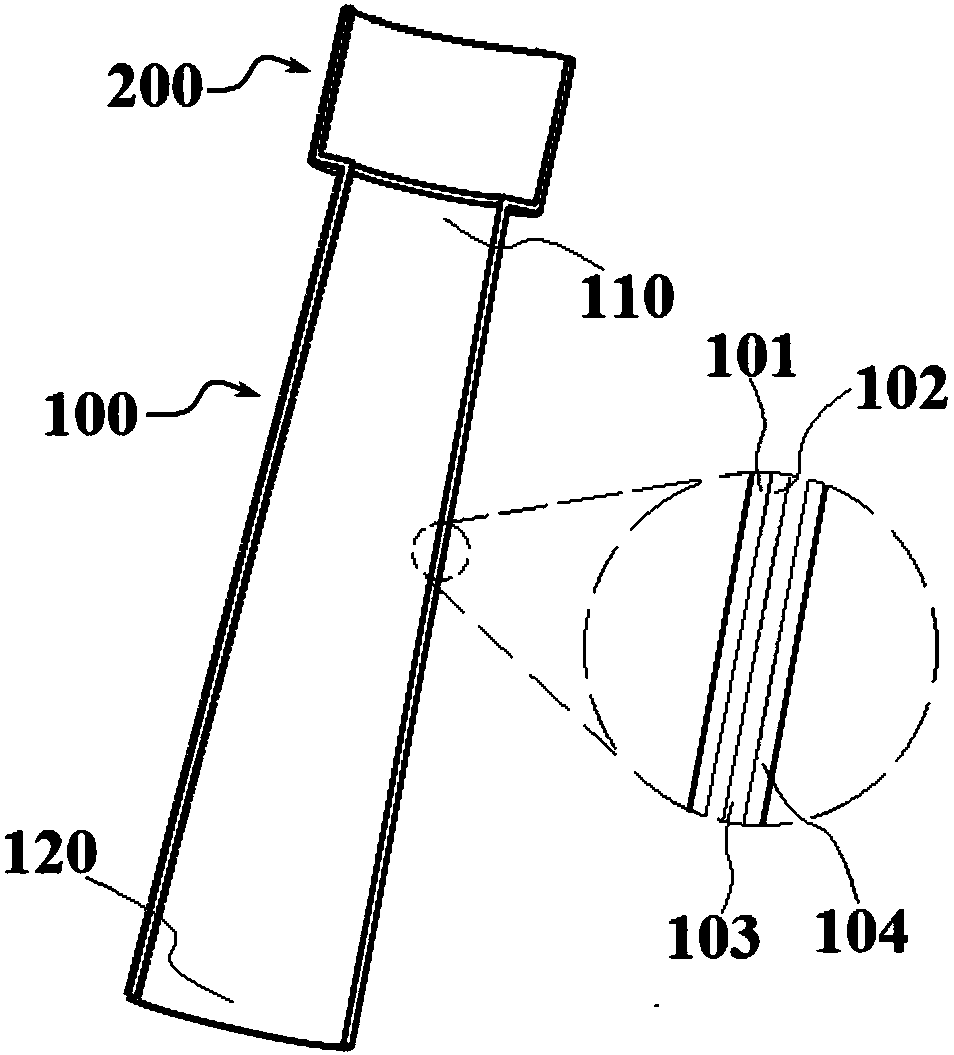

[0051] The basic content of this embodiment is the same as that of Embodiment 1, the difference is that the outer casing 104, the heat insulation layer 102 and the refractory material layer 101 (eg figure 2 shown); the shell 104 is made of a steel structure with high mechanical strength, and the heat insulating layer 102 is made of heat insulating material, wherein the heat insulating material is glass fiber, asbestos, rock wool or silicic acid salt, or a combination of the above; the thermal insulation material of the thermal insulation layer 102 can effectively limit the heat of the molten steel in the protective sleeve 100 to dissipate heat to the outside of the protective sleeve 100, thereby reducing the temperature loss during the tapping process, thereby reducing the tapping. temperature, saving energy consumption in steelmaking. The refractory material layer 101 is disposed on the inner wall of the protective sleeve 100, and the refractory material layer 101 is made of...

Embodiment 3

[0053] The basic content of this embodiment is the same as that of Embodiment 2, except that a gap layer 103 (such as figure 2 shown), that is, a gap is set between the outer shell 104 and the heat insulating layer 102, and a gap layer 103 is formed. Layer 103 is filled with air. The void layer 103 between the casing 104 and the heat insulating layer 102 changes the heat transfer conditions of the protective sleeve 100, thereby limiting the heat transfer of molten steel in the protective sleeve 100 to the outside, and reducing the heat loss during the tapping process of the molten steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com