Airtight oxygen-rich negative pressure efficient smelting furnace directional smelting clean production process

A technology for directional smelting and clean production, applied in the direction of improving process efficiency, can solve the problems of low utilization of enthalpy in the reduction and smelting reaction of waste residue, poor flue gas recovery effect, and high implementation cost, so as to increase the reaction atmosphere and smelting effect. Solve the effect of intermittent production and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

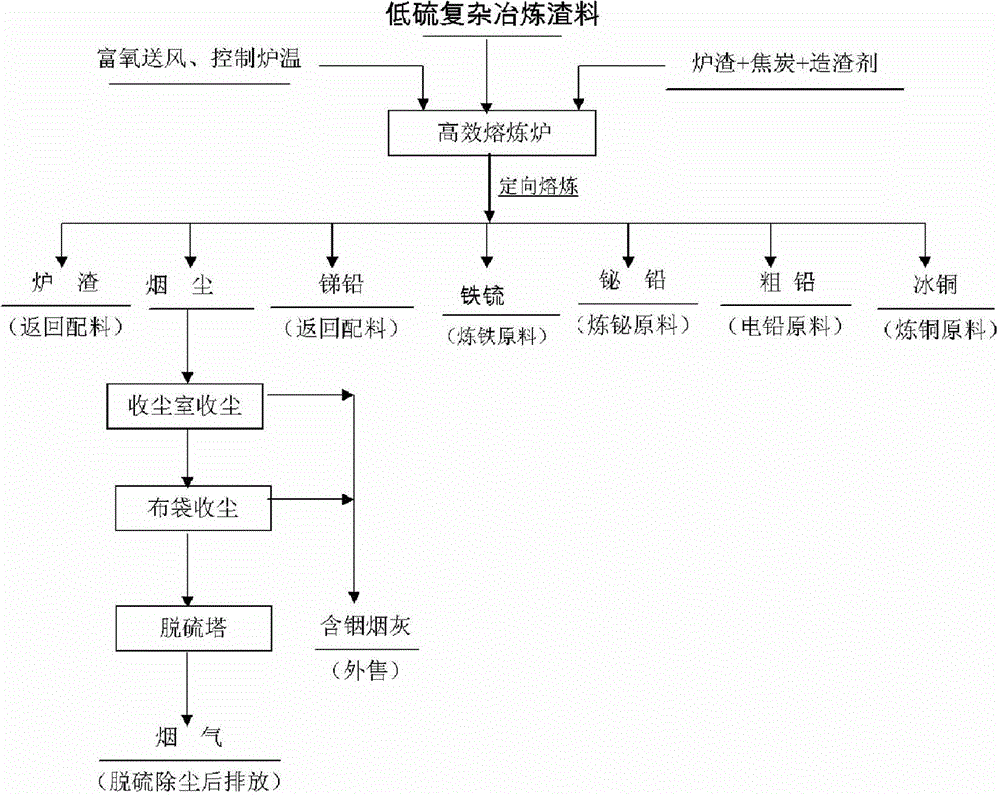

[0020] A clean production process for directional smelting of a closed oxygen-enriched negative pressure high-efficiency smelting furnace, which adopts a high-efficiency smelting furnace with a fully enclosed transmission and feeding system, oxygen-enriched air supply, a fully enclosed continuous negative pressure system, a DCS control system and a wet desulfurization system; The low-sulfur complex smelting slag, slag, coke and slagging agent are mixed and pressed and conveyed through the belt, and fed from the feed port of the high-efficiency smelting furnace; coal gas or natural gas and coking coal are used as heating fuel for reduction smelting, and are fed from the bottom and side Combustion reaction occurs after feeding in, and the temperature in the furnace is controlled to be kept at 1050-1400°C; coal gas or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com