Fused quartz uniform smelting device

A fused silica, uniform technology, used in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., to avoid solidification, reasonable structure, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

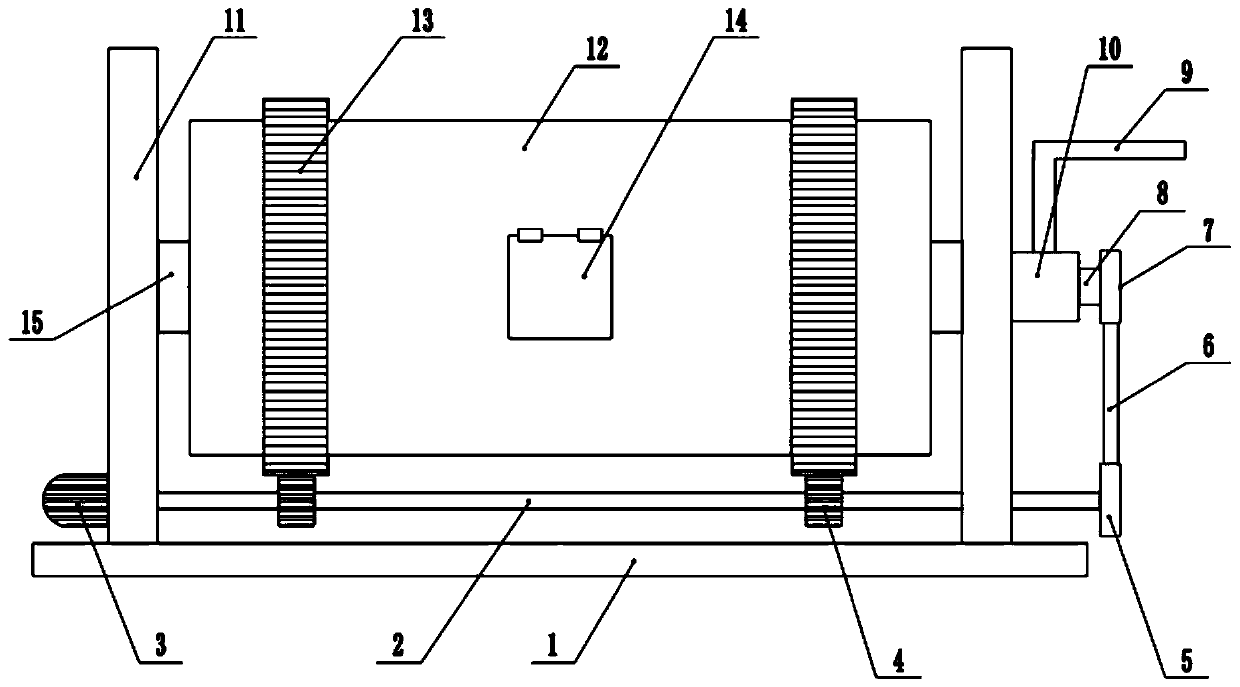

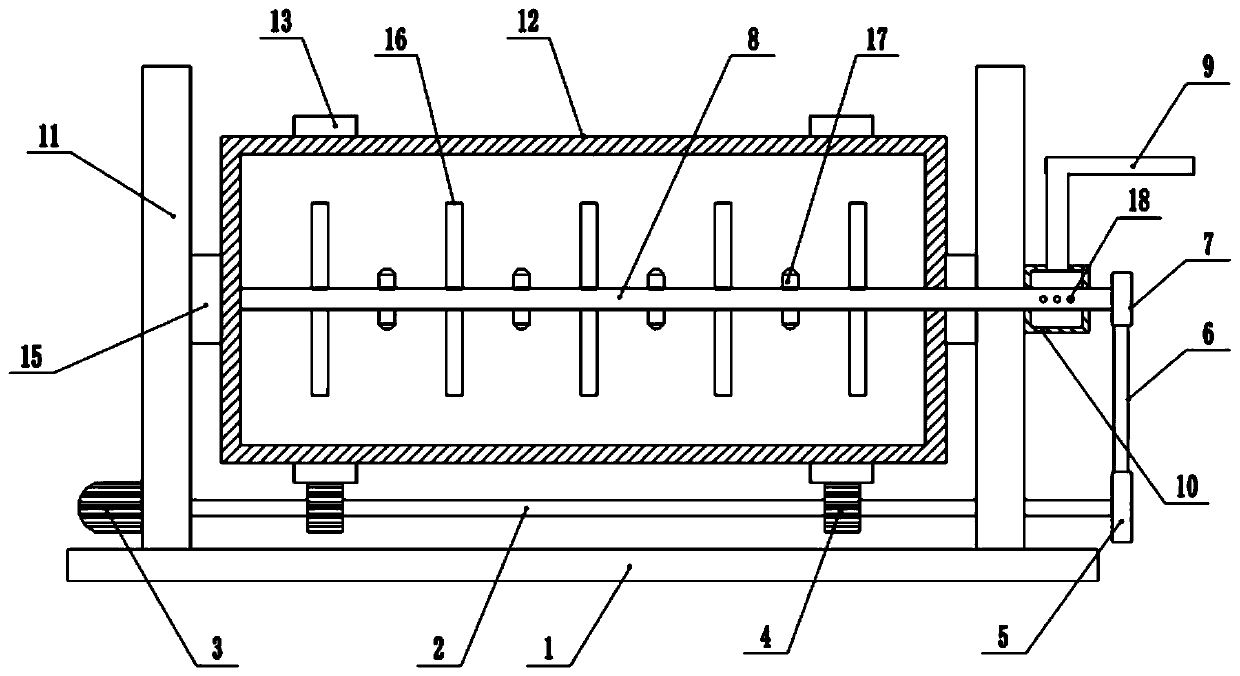

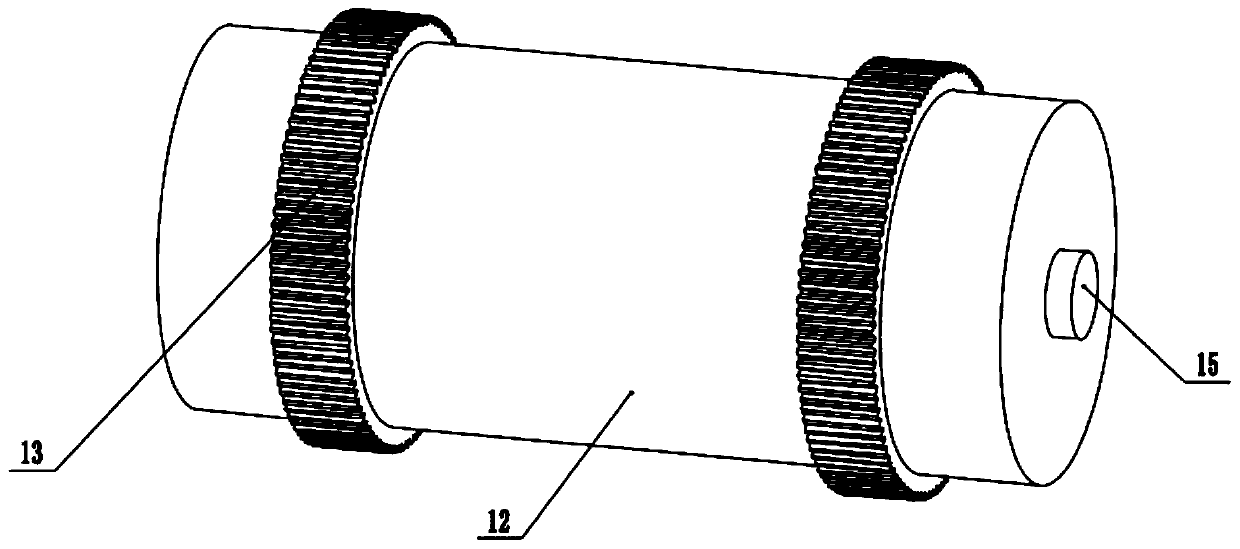

[0025] refer to Figure 1~3 , in an embodiment of the present invention, a fused silica uniform smelting device includes a fixed base plate 1, a support frame 11 is installed on both sides of the upper end of the fixed base plate 1, a bearing housing 15 is installed in the middle of the inner side of the support frame 11, and a melting furnace is installed between the bearing housings 15. cylinder 12, the smelting cylinder 12 can rotate along the bearing seat 15, and the outer middle part of the smelting cylinder 12 is provided with an inlet and outlet door 14, which is used to put the quartz to be smelted into the inside of the smelting cylinder 12, and the two outer sides of the smelting cylinder 12 The ring gear 13 is installed on the side, and the lower end of the ring gear 13 is meshed with a column gear 4, and the middle part of the column gear 4 is installed with a rotating shaft 2, and the left side of the rotating shaft 2 passes through the support frame 11 on the left...

Embodiment 2

[0027] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the rotating motor 3 is a double-steering stepping motor, which ensures that the rotating motor 3 can rotate the rotating shaft 2 in both directions.

[0028] In the present invention, when working, the fused silica is placed inside the melting cylinder 12 through the inlet and outlet door 14, and then the rotating motor 3 is started, and the rotating motor 3 drives the rotating shaft 2 to rotate. On the one hand, the column gear 4 is rotated, and the ring gear 13 Engagement makes the smelting cylinder 12 rotate, ensuring the mixing of the internal fused silica, and on the other hand, through the cooperation between the driving pulley 5, the belt 6 and the driven pulley 7, the smelting shaft 8 is rotated, and is connected with the melting cylinder The direction of rotation of 12 is opposite. At this time, the combustion column 17 is burning, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com