Smelting process of low-grade scrap copper

A waste miscellaneous copper, low-grade technology, applied in the field of copper smelting, can solve the problems of material shape and size restrictions, melt splashing, damage to the furnace lining, etc., and achieve the effect of flexible operation and feeding methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]1) Mixing waste miscellaneous copper, coal and flux quartz stone to form a batch, the moisture content of the batch is lower than 10%;

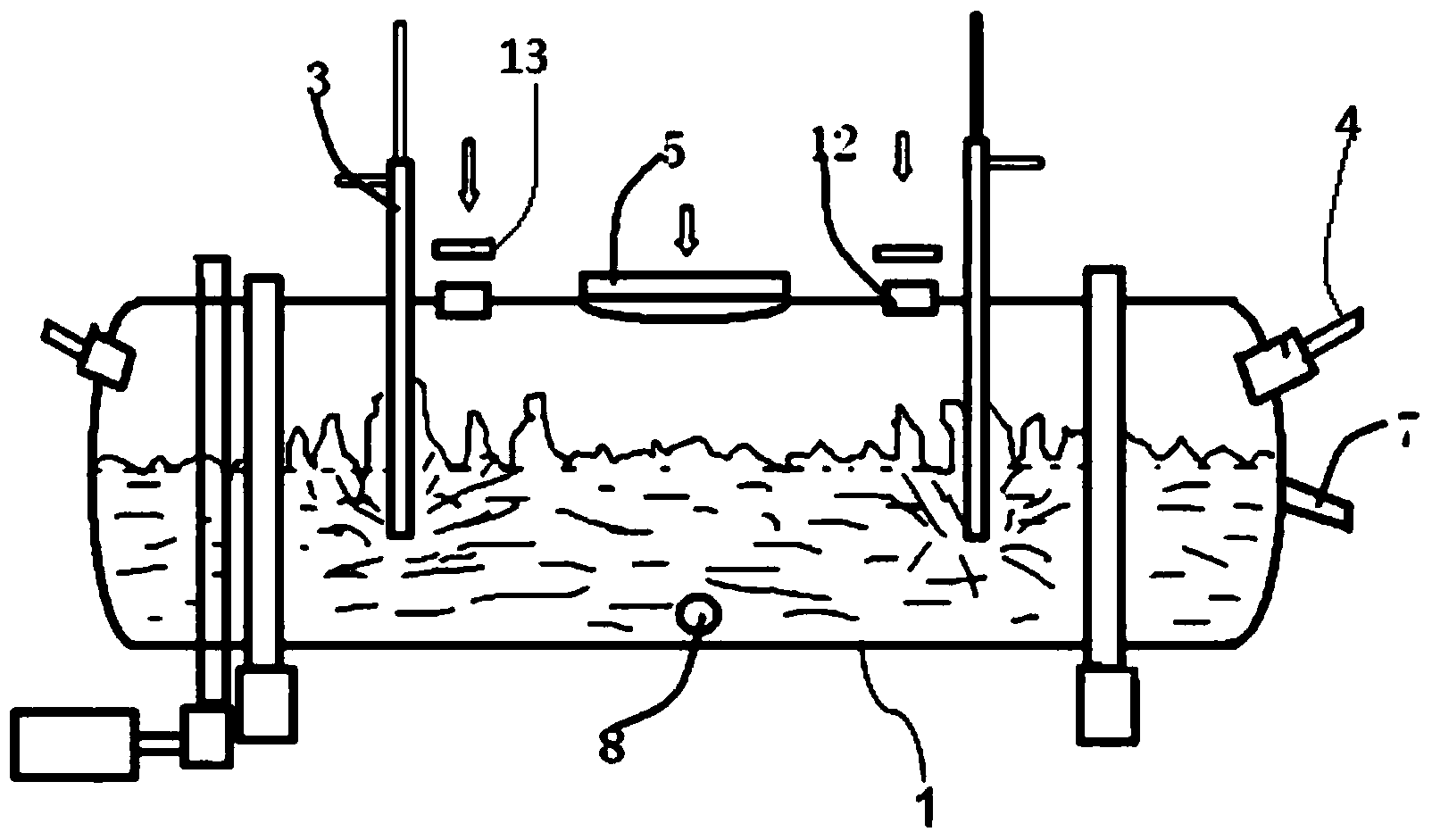

[0034] 2) Put coal, water-quenched slag, sulfide ore and flux into the horizontal top-blowing furnace 1 according to the weight ratio of 15:60:25:5 for mixing, and the top-blowing lance 3 sprays into the top-blowing furnace 1 Oxygen and natural gas are burned until the above-mentioned materials are melted, the flux is quartz stone, and the temperature in the top-blowing furnace 1 is controlled at 1250°C-1300°C; the content of magnetic iron oxide in the slag in the top-blowing furnace 1 is regularly detected, and kept The percentage of magnetic iron oxide in the slag is less than or equal to 20%;

[0035] 3) Add the ingredients prepared in step 1 continuously to the top-blowing furnace 1 at a speed of 5t / h-70t / h, and regularly detect the content of copper, iron, silicon oxide and magnetic iron oxide in the slag in the top-blowing furnace...

Embodiment 2

[0039] 1) Mixing waste miscellaneous copper, coal and flux quartz stone to form a batch, the moisture content of the batch is lower than 10%;

[0040] 2) Put coal, water-quenched slag, sulfide ore and flux into the horizontal top-blowing furnace 1 according to the weight ratio of 10:55:20:2 for mixing, and the top-blowing lance 3 sprays into the top-blowing furnace 1 Oxygen and natural gas are burned until the above materials are melted, the flux is quartz stone, and the temperature in the top-blowing furnace 1 is controlled at 1250-1300°C; the content of magnetic iron oxide in the slag in the top-blowing furnace 1 is regularly detected to keep the slag The percentage content of magnetic iron oxide in is less than or equal to 20%;

[0041] 3) Continuously add the ingredients obtained in step 1 into the top-blowing furnace 1 at a speed of 60-100t / h, regularly detect the contents of copper, iron, silicon oxide and magnetic iron oxide in the slag in the top-blowing furnace 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com