A kitchen material conveying system and kitchen automatic cooking system

An automatic cooking and conveying system technology, applied in the direction of conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of single automatic feeding and feeding methods, inability to flexibly switch conveying pipelines, cumbersome methods, etc., to achieve integration Coordinated control, safe and reliable feeding process, and the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail through the following embodiments. However, those skilled in the art should understand that the following embodiments do not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

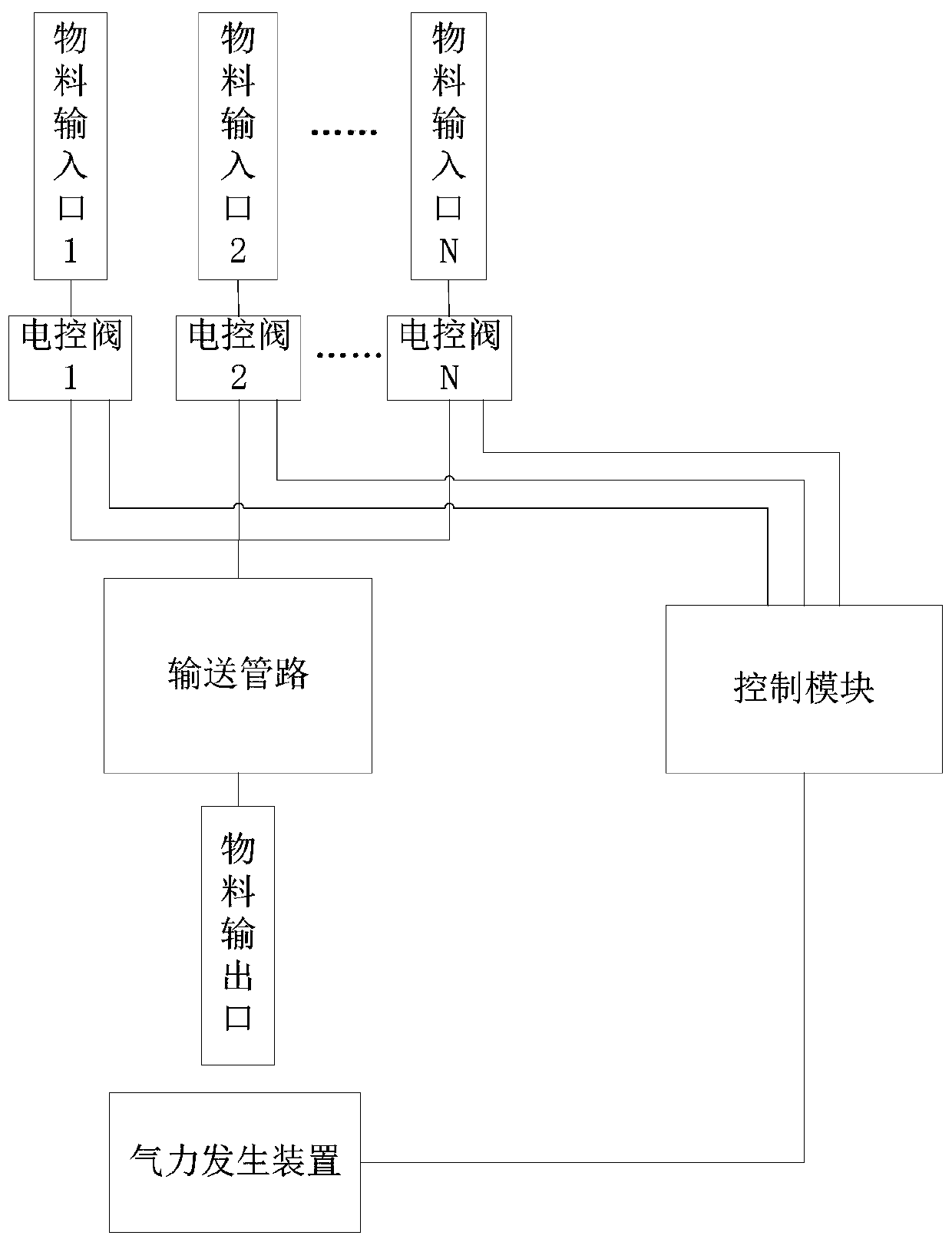

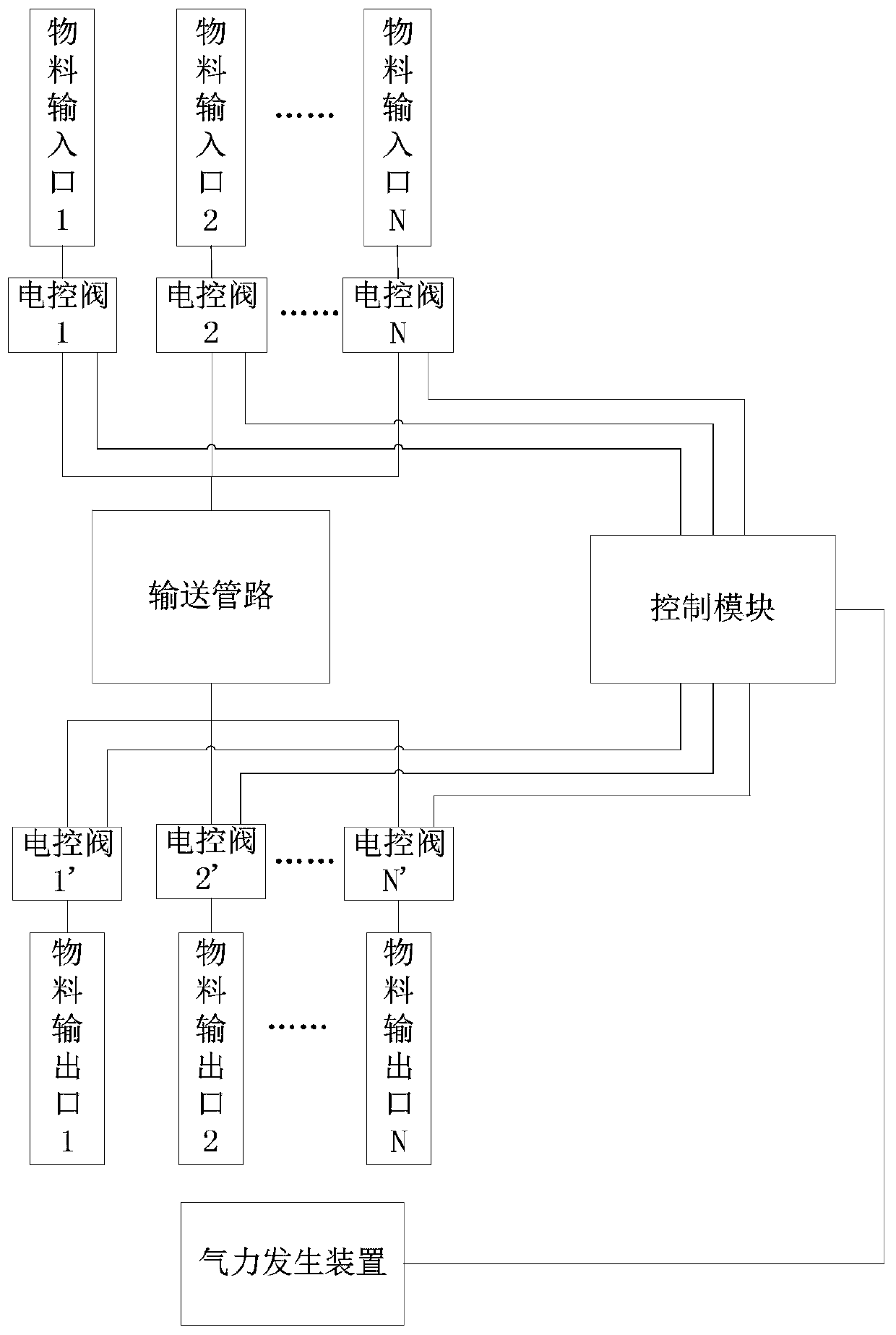

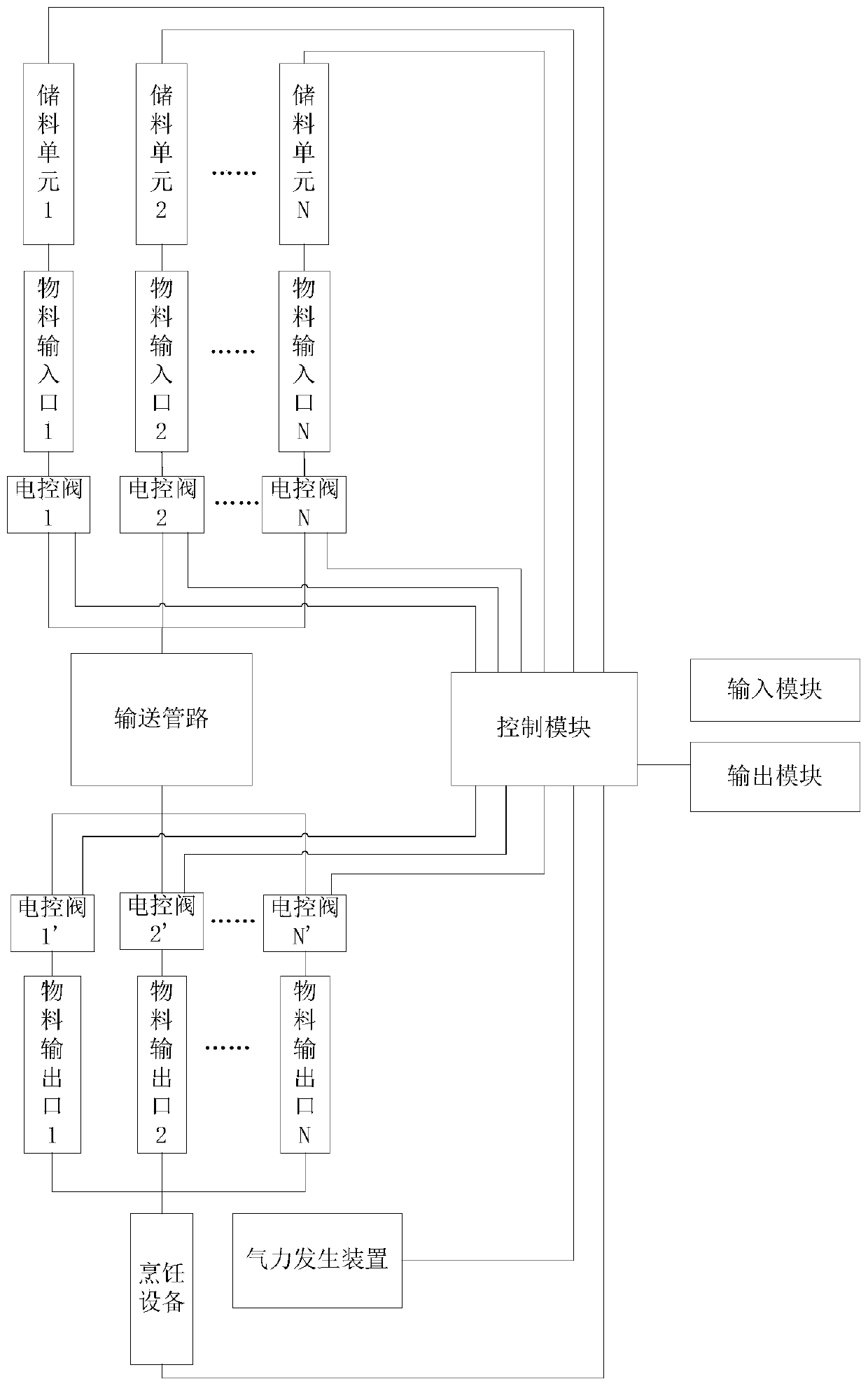

[0042] Refer to attached figure 1 As shown, it is a schematic diagram of a structural composition of the kitchen material conveying system proposed by the present invention, which is composed of the attached figure 1 It can be seen that the kitchen material conveying system proposed by the present invention is mainly composed of a conveying pipeline, a material input port, a material output port, an electric control valve, a pneumatic generating device and a control module.

[0043] Specifically, the conveying pipeline is a channel for conveying solid materials by pneumatic force, wherein a plurality of material inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com