Multi-station automatic bottom expansion bolt feeding system and feeding method

A feeding system and multi-station technology, which is applied in the feeding field of the automatic bottom-expanding bolt feeding system, can solve the problems of high cost of the driving system, many personnel required, and high labor intensity, so as to reduce labor intensity and save costs. , the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

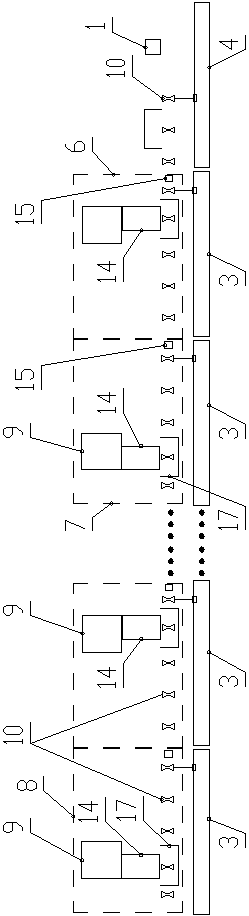

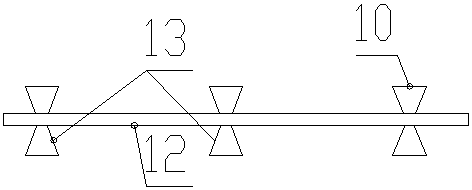

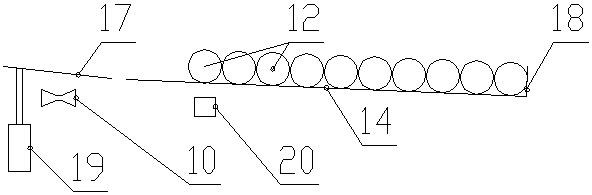

[0062] Such as Figure 1 to Figure 9 As shown, the multi-station automatic bottom expansion bolt feeding system of the present invention includes a flaw detector 1, a chain conveying mechanism and a PLC control system 2, and the PLC control system 2 has a built-in memory;

[0063] The chain conveying mechanism includes a station chain conveying mechanism 3 and an upstream chain conveying mechanism 4; the station chain conveying mechanism 3 is arranged along the processing station; the conveying direction of the raw material rod 12 to be conveyed (that is, the anchor rod to be processed) is the downstream direction ;

[0064] The processing stations are respectively the first processing station 6, the second processing station 7 to the Nth processing station 8 from upstream to downstream, and N is an even number. In this embodiment, N=10, that is to say, there are 10 processing stations in total. Each processing station is equipped with a thread rolling machine 9 (the thread r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com