Smelting method for retaining hot dreg of converter

A smelting method and converter technology, which is applied in the manufacture of converters, etc., can solve problems such as easy splashing and difficulty in accurately controlling the amount of hot slag remaining in the converter, and achieve the effects of reducing emissions, stabilizing the blowing process, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

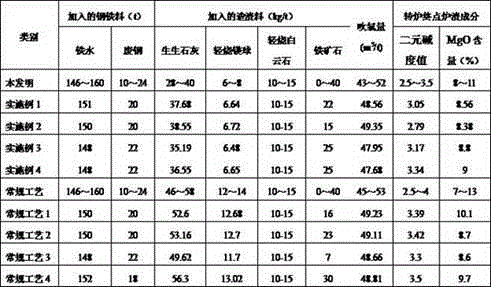

Examples

Embodiment Construction

[0018] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0019] A smelting method for retaining converter hot slag disclosed by the present invention comprises the following steps:

[0020] a. Slag dumping treatment, slag dumping treatment is carried out after the converter is tapped, and the tilting angle of the converter is controlled at 95-115 degrees. By observing the display value of the slag tank scale, 30-50% of the total slag is poured out, and 50-70% is left The slag is in the converter, and then the converter is shaken back to zero;

[0021] b. Furnace protection by slag splashing, add a certain amount of light-burned magnesium balls and light-burned dolomite to the slag left in the converter in step a for slag-splashing furnace protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com