Method and apparatus for efficiently purifying silicon material after medium smelting

A medium smelting and purification method technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry and other directions, can solve the problems of low yield of qualified silicon material, cumbersome production process, high production cost, and achieve increased operational complexity and high efficiency. Smelting, the effect of reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

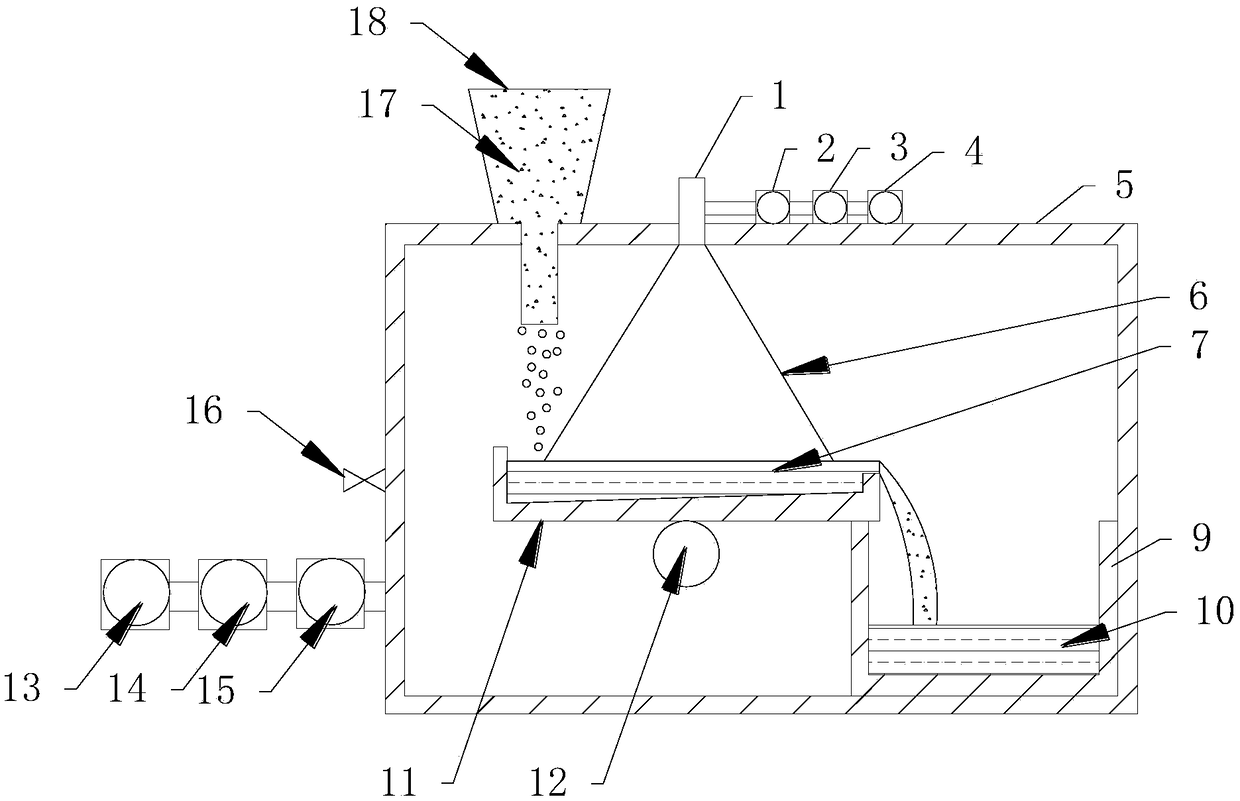

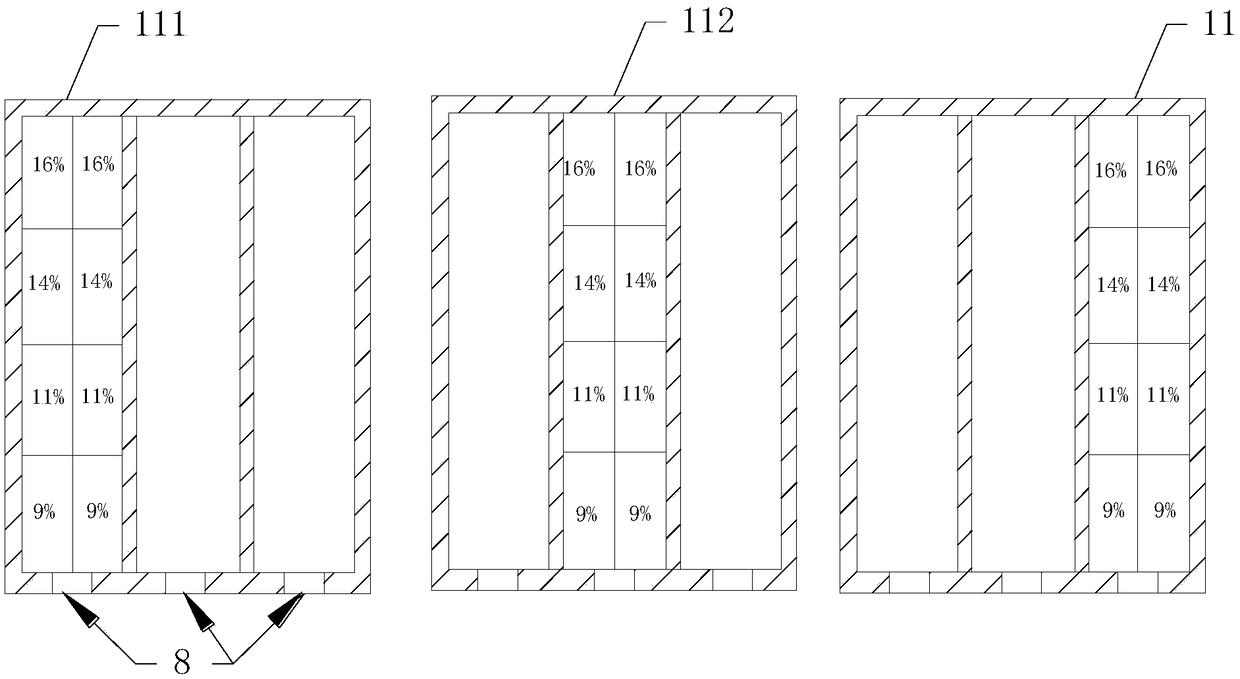

[0040] Such as Figure 2-Figure 3As shown, a device for efficient purification of silicon material after medium smelting, the structure of the melting crucible 11 is inclined from the rear end to the guide liquid port 8; there are several intervals in the melting crucible 11, and each inner groove corresponds to a melting tank. One smelting tank corresponds to one liquid guide port 8 .

[0041] The inclination angle of the melting crucible is 5-10°. Due to the flow of silicon liquid and the downward deposition of silicon carbide, the amount of silicon carbide deposited near the back end of the melting crucible is more, and the closer to the liquid guide port, the smaller the amount of silicon carbide deposited. The melting crucible is designed to be inclined from the rear end to the guide liquid port. , to avoid excessive deposition of silicon carbide at the back end. In the later process of smelting, the melting capacity of the silicon material due to the depth of the molten...

Embodiment 2

[0062] : The vacuum suction structure on one side of the body of furnace 5 is a mechanical pump I13, a Roots pump I14, and a diffusion pump I15 connected in sequence, and the end of the diffusion pump is connected to the body of furnace to take away the air in the furnace chamber to build a vacuum environment The vacuum suction structure on one side of the electron gun 1 is a molecular pump 2, Roots pump II 3, and mechanical pump II 4 connected in sequence, and the end of the molecular pump is connected with the electron gun 1 to build the vacuum conditions required for electron beam smelting.

[0063] All the other are identical with embodiment 1.

Embodiment 3

[0065] One side of the furnace body 5 is provided with an air charging valve 16 .

[0066] All the other are identical with embodiment 1 or embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com