A method for continuous smelting carbide slag

A technology of carbide slag and titanium carbide, which is applied in the field of metallurgy, can solve the problem that carbide slag cannot be continuously smelted in large quantities, and achieve the effects of high recycling value, stable CO concentration, and efficient smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

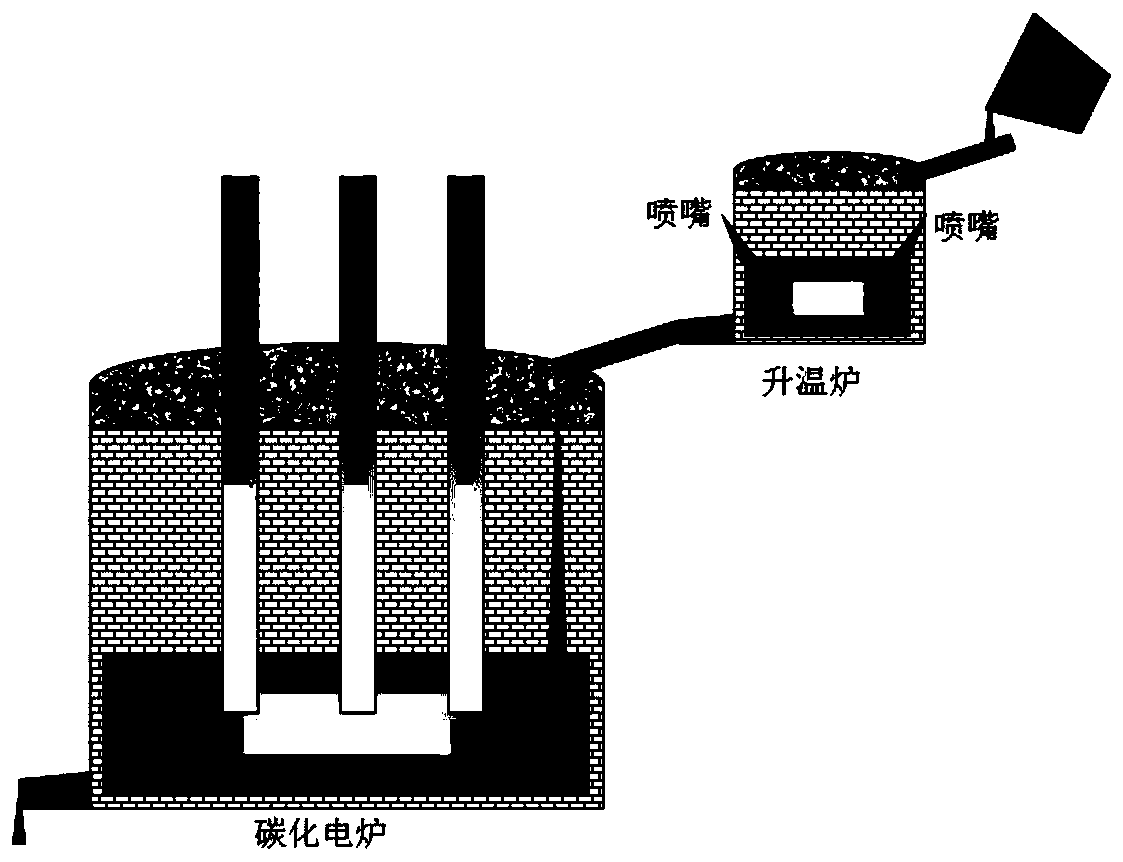

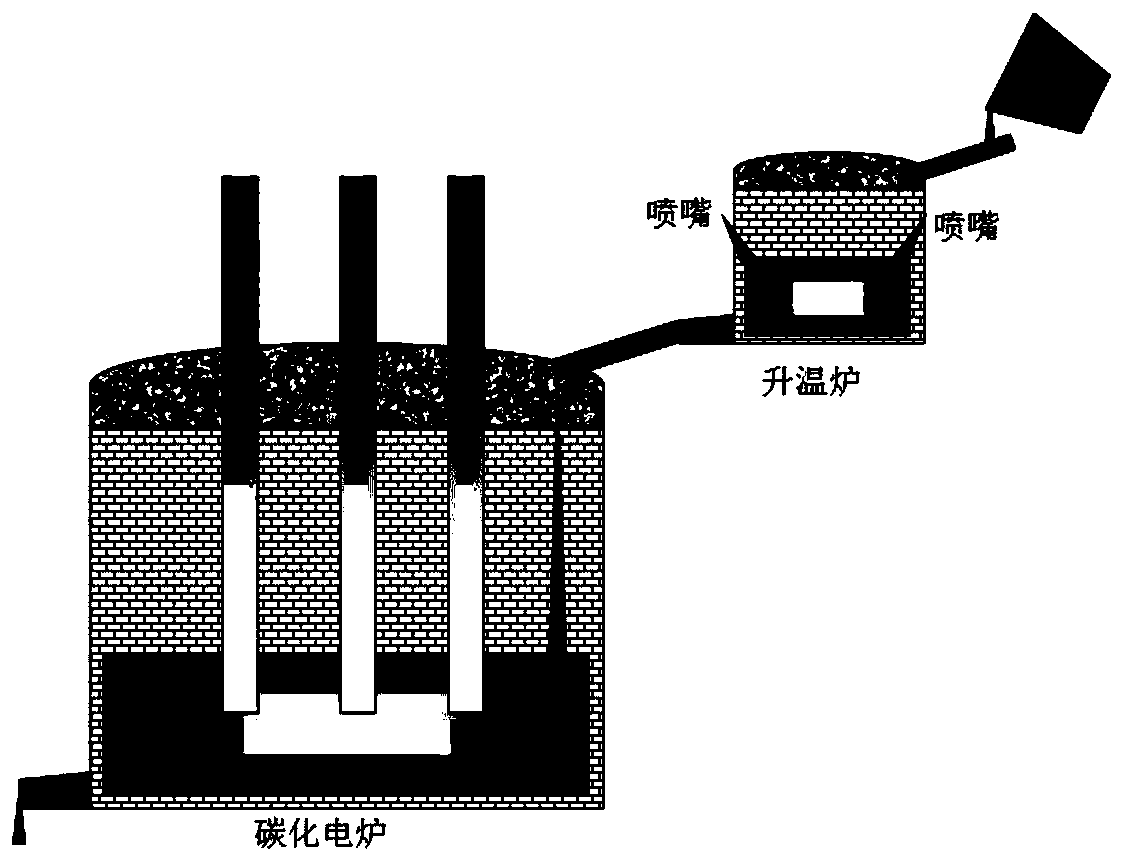

Image

Examples

Embodiment 1

[0026] This invention was implemented in a certain factory. In the working area, a carbonization electric furnace had a nominal capacity of 65t. Two small heating furnaces were installed in the north-south direction around the carbonization furnace. The nominal capacity of the heating furnaces was both 30t. The content of total titanium in the molten blast furnace slag is 13.60%, and the content of titanium dioxide is 23.32%. It is transported to the production operation area by a slag tank truck, and is directly poured into the heating furnace after the shell is broken by a heavy hammer. The heating furnace uses natural gas to heat the slag, and the heating time is about 56 minutes At the end of heating, the infrared thermometer measured the surface temperature of the slag to be 1582°C, and the team opened the slag. Sampling and chemical analysis showed that the total Ti content in the slag was 13.43%, the TiC content was 5.6%, and the titanium dioxide in the slag was converted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com