Efficient full-iron steelmaking method allowing molten iron to be added into pig iron in electric-arc furnace

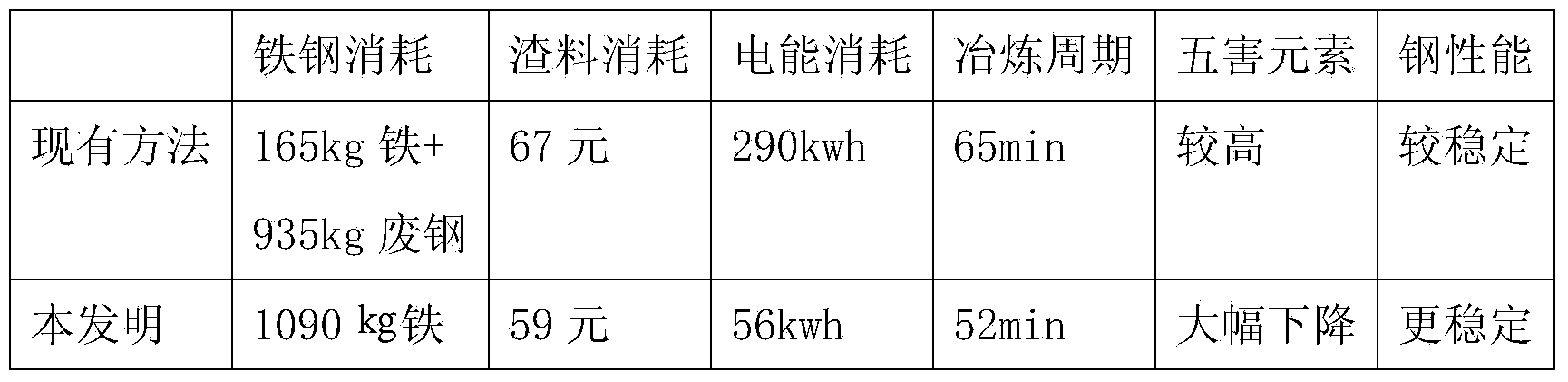

An electric arc furnace and blast furnace molten iron technology, applied in electric furnace, process efficiency improvement, furnace and other directions, can solve the problems of insufficient stability of steel performance and insufficient purity, and achieve the effects of reducing hazards, reducing production costs, and stabilizing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, leave 7500kg of slag in the electric arc furnace, then add 61000kg of blast furnace molten iron from the door of the electric arc furnace, add 500kg of lime into the electric arc furnace at the same time, and start blowing oxygen; raise the electric arc furnace at a heating rate of 8-10°C / min When the temperature rises to 1580°C, add 8000kg of pig iron blocks from the feeder to cool down, and add 1500kg of slag to cool down and adjust the slag. 3 / t steel; when the mass concentration of carbon in molten steel is less than 1.0%, add 800kg of slag, and when the mass concentration of carbon in steel drops below 0.8%, change the mode of blowing oxygen to slag, and divide it into two to three batches Add the remaining 1200kg of slag one time until the mass concentration of carbon is less than 0.20%; finally adjust the temperature and the content of C and P in the steel to the tapping requirements, and turn over the furnace to tap.

Embodiment 2

[0033] First, leave 8000kg of slag in the electric arc furnace, then add 63000kg of blast furnace molten iron from the door of the electric arc furnace, add 500kg of lime into the electric arc furnace at the same time, and start blowing oxygen; raise the temperature of the electric arc furnace at a rate of 8-10°C / min When the temperature rises to 1580°C, add 9000kg of pig iron blocks from the feeder to cool down, and add 1500kg of slag to cool down and adjust the slag. 3 / t steel; when the mass concentration of carbon in molten steel is less than 1.0%, add 800kg of slag, and when the mass concentration of carbon in steel drops below 0.8%, change the mode of blowing oxygen to slag, and divide it into two to three batches Add the remaining 1200kg of slag one time until the mass concentration of carbon is less than 0.20%; finally adjust the temperature and the content of C and P in the steel to the tapping requirements, and turn over the furnace to tap.

Embodiment 3

[0035] First, leave 8000kg of slag in the electric arc furnace, then add 65000kg of blast furnace molten iron from the door of the electric arc furnace, add 500kg of lime into the electric arc furnace at the same time, and start blowing oxygen; raise the temperature of the electric arc furnace at a rate of 8-10℃ / min When the temperature rises to 1580°C, add 9000kg of pig iron blocks from the feeder to cool down, and add 1500kg of slag to cool down and adjust the slag. 3 / t steel; when the mass concentration of carbon in molten steel is less than 1.0%, add 800kg of slag, and when the mass concentration of carbon in steel drops below 0.8%, change the mode of blowing oxygen to slag, and divide it into two to three batches Add the remaining 1200kg of slag one time until the mass concentration of carbon is less than 0.20%; finally adjust the temperature and the content of C and P in the steel to the tapping requirements, and turn over the furnace to tap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com