The preparation method and ironmaking raw material of iron ore hot pressure contains carbon balls

A technology for iron-making raw materials and carbon pellets is applied in the field of metallurgy, which can solve the problems of high requirements for heat-resistance and heat preservation performance of hot-pressing equipment, high hot-pressing temperature and high preheating temperature, achieve excellent reduction performance, and simplify the process. Process, effect of good microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

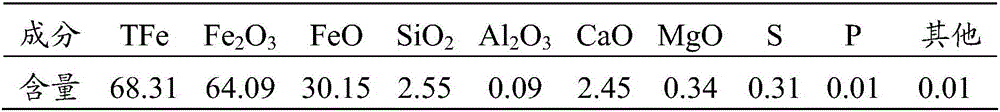

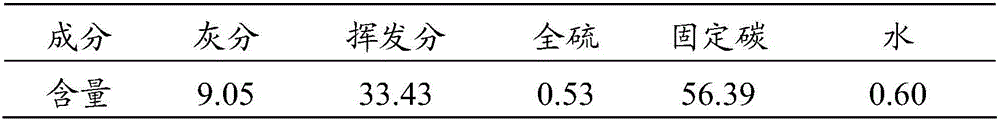

[0021] Firstly, iron ore fines with particle sizes less than 0.15 mm, 1 / 3 coking coal and metallurgical lime are evenly mixed to obtain the first material. Wherein, the content of the iron ore powder in the first material is 63.3wt%, and the iron ore powder whose particle size is less than 0.075mm accounts for 60% of the total amount of iron ore powder added by volume percentage, and the main components of the iron ore powder are shown in Table 1 The content of 1 / 3 coking coal is 32.6wt%, and the 1 / 3 coking coal whose particle size is less than 0.075mm accounts for 90% of the total addition amount of 1 / 3 coking coal by volume percentage, and the chemical composition of 1 / 3 coking coal is shown in Table 2 The content of metallurgical lime is 4.1wt%, and the metallurgical lime whose particle size is less than 0.075mm accounts for 100% of the total amount of metallurgical lime added by volume percentage, and the effective flux of metallurgical lime is 85wt%.

[0022] Secondly, af...

Embodiment 2

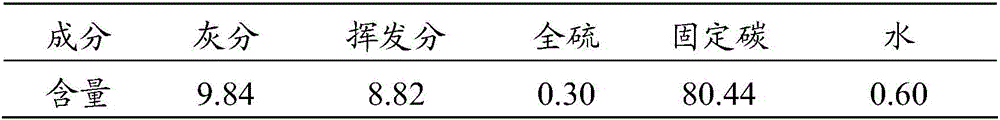

[0028] Firstly, iron ore powder with a particle size less than 0.15mm, 1 / 3 coking coal, anthracite coal powder and metallurgical lime are evenly mixed to obtain the first material. Wherein, the content of the iron ore powder in the first material is 72.7wt%, and the iron ore powder whose particle size is less than 0.075mm accounts for 70% of the total amount of iron ore powder added by volume percentage, and the main components of the iron ore powder are shown in Table 1 The content of 1 / 3 coking coal is 24.0wt%, and the 1 / 3 coking coal whose particle size is less than 0.075mm accounts for 90% of the total addition amount of 1 / 3 coking coal by volume percentage, and the chemical composition of 1 / 3 coking coal is shown in Table 2 The content of anthracite coal powder is 2.3wt%, and the anthracite coal powder with particle size less than 0.075mm accounts for 90% of the total addition of anthracite coal powder by volume percentage. The chemical composition of anthracite coal powde...

Embodiment 3

[0035] Firstly, iron ore fines with particle sizes less than 0.15mm, 1 / 3 coking coal, weakly cohesive coal dust and metallurgical lime are uniformly mixed to obtain the first material. Wherein, the content of the iron ore powder in the first material is 78.6wt%, and the iron ore powder with a particle size less than 0.075mm accounts for 60% of the total amount of iron ore powder added by volume percentage, and the main components of the iron ore powder are shown in Table 1 Shown; The content of 1 / 3 coking coal is 18.3wt%, and the 1 / 3 coking coal with particle size less than 0.075mm accounts for 90% of the total addition amount of 1 / 3 coking coal by volume percentage, and the chemical composition of 1 / 3 coking coal is shown in Table 2 Shown; The content of weak caking coal pulverized coal is 2.0wt%, and the anthracite pulverized coal with particle size less than 0.075mm accounts for 90% of the total addition amount of anthracite coal pulverized by volume percentage, and the chem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com