Method and device for efficient removal of impurity oxygen from polysilicon by electron beam melting

A technology of electron beam smelting and electron beam smelting furnace, which is applied in the field of polysilicon purification, can solve the problems of poor oxygen removal effect, poor oxygen removal effect, and difficult operation, so as to shorten the oxygen removal time and increase the silicon liquid Surface area, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

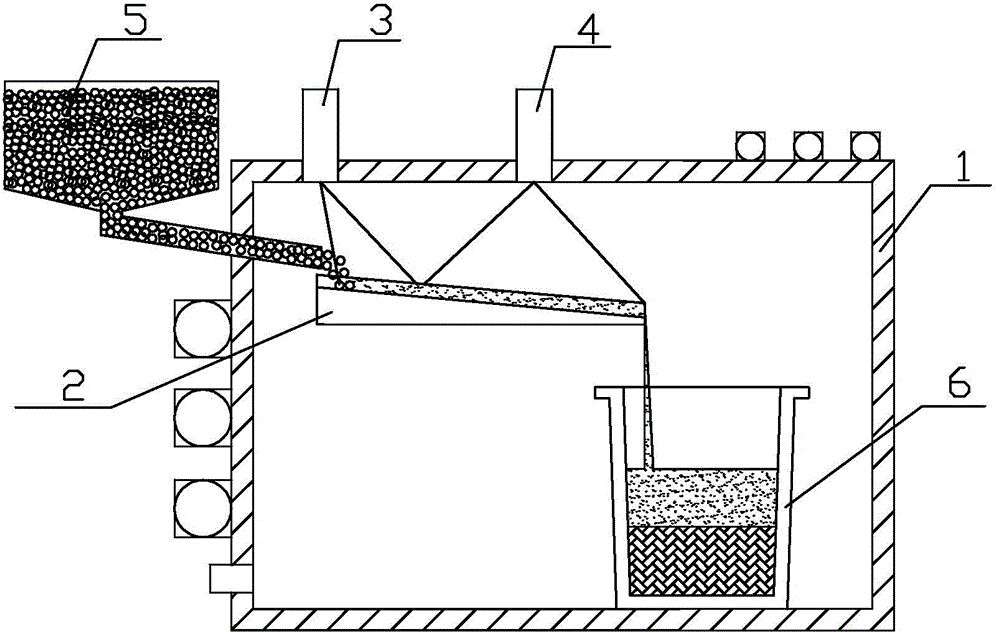

[0026] like figure 1 As shown, a device for efficiently removing impurity oxygen in polysilicon by electron beam smelting includes a furnace body 1, and a water-cooled diversion groove 2 is arranged on the upper part of the furnace body 1. The diversion groove 2 is inclined from top to bottom, and the furnace body The side wall of 1 is connected with a feeding mechanism 5, and the discharge port of the feeding mechanism 5 is located above the high end of the diversion tank 2; the top of the furnace body 1 above the diversion tank 2 is connected with an electron gun 3 for melting and a melting furnace. An electron gun 4 is used; a solidification crucible 6 is provided at the inner bottom of the furnace body 1 below the pouring port of the diversion tank 2 .

[0027] The solidification crucible 6 is a copper crucible with water cooling. For the solidified crucible 6, both graphite crucible and quartz crucible can be used, but when the silicon liquid is poured downward, it is ea...

Embodiment 2

[0030] The device in Example 1 is used to efficiently remove impurity oxygen in polysilicon by electron beam smelting.

[0031](1) Material preparation: wash and dry the polysilicon material with a particle size of 10-12 mm and an oxygen content of 20 ppmw and put it into the feeding mechanism 5; put the silicon material that has been purified by electron beam melting into the inner bottom of the solidification crucible 6 as a solidification Primer;

[0032] (2) Pretreatment: Turn on the cooling water circulation for the electron beam melting furnace and diversion tank 2, vacuumize the inside of the electron beam melting furnace to below 0.05Pa, and vacuum the electron gun 3 for melting and the electron gun 4 for melting Processing, pumping to below 0.005Pa, and then preheating, set the beam current of the electron beam to 150mA, after preheating for 15min, turn off the preheating;

[0033] (3) Smelting and purification: start the feeding mechanism 5, continuously add silicon...

Embodiment 3

[0035] The device in Example 1 is used to efficiently remove impurity oxygen in polysilicon by electron beam smelting.

[0036] (1) Material preparation: wash and dry the polysilicon material with a particle size of 10-12 mm and an oxygen content of 10 ppmw and put it into the feeding mechanism 5; put the silicon material that has been purified by electron beam melting into the inner bottom of the solidification crucible 6 as a solidification Primer;

[0037] (2) Pretreatment: Turn on the cooling water circulation for the electron beam melting furnace and diversion tank 2, vacuumize the inside of the electron beam melting furnace to below 0.05Pa, and vacuum the electron gun 3 for melting and the electron gun 4 for melting Processing, pumping to below 0.005Pa, and then preheating, set the beam current of the electron beam to 200mA, preheat the electron gun for 10 minutes, and then turn off the preheating;

[0038] (3) Melting and purification: start the feeding mechanism 5, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com