Methods and apparatus for high speed object handling

A technology of disposal system and processing station, applied in the field of high-speed object disposal, which can solve the problems of low throughput and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

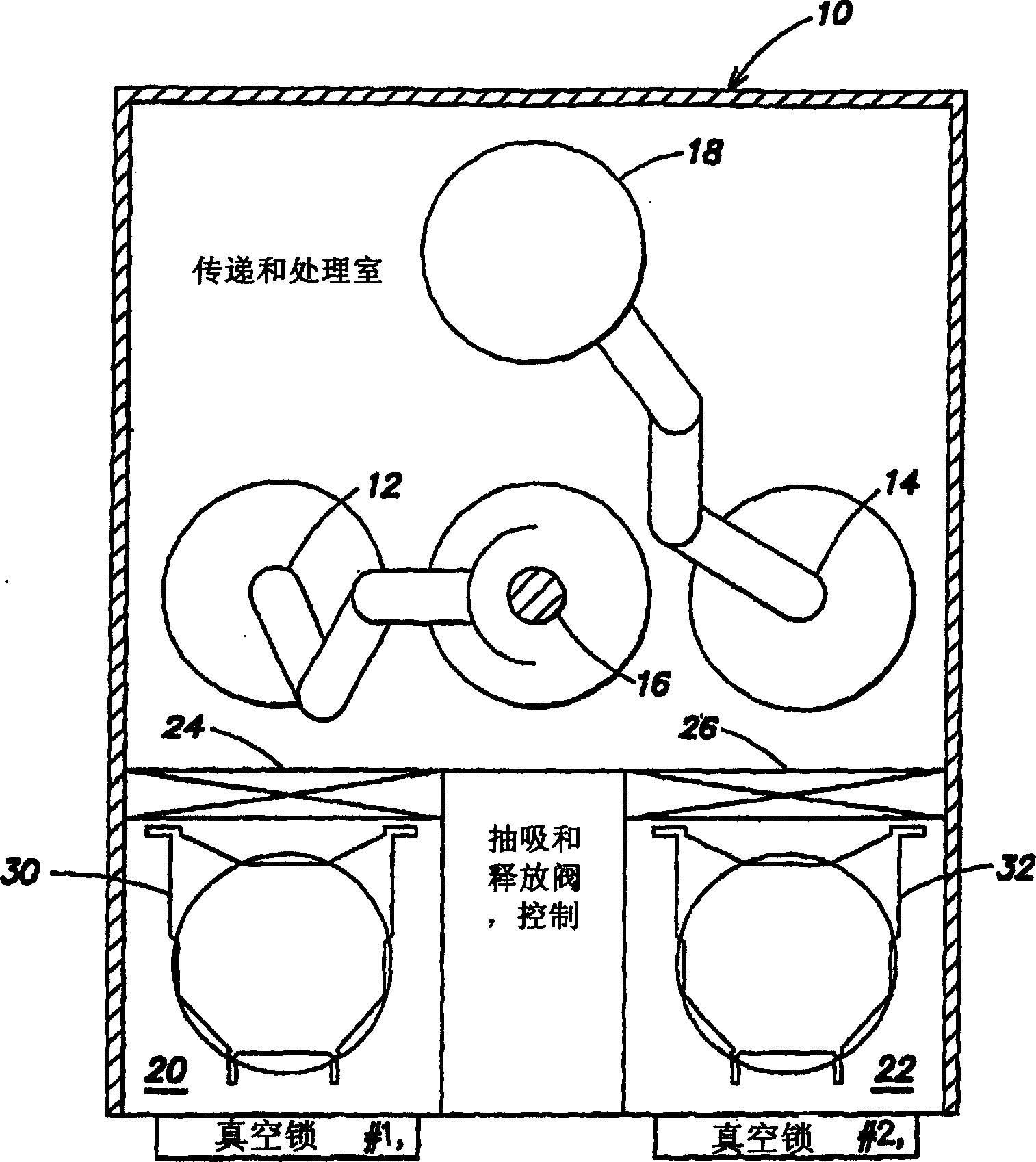

[0028] A prior art wafer handling system of the type disclosed in the aforementioned US Patent No. 5,486,080 is shown in FIG. 1 . The vacuum chamber 10 contains a first robot 12 , a second robot 14 , a transfer station 16 and a processing station 18 . Vacuum locks 20 and 22 communicate with vacuum chamber 10 through isolation valves 24 and 26, respectively. Cassettes 30 and 32 each containing a plurality of semiconductor wafers are placed in corresponding vacuum locks 20 and 22 .

[0029] In operation, wafers are removed from cassette 30 by first robot 12 and placed on transfer station 16 . Transfer station 16 includes wafer support and position sensors that determine the displacement and rotation errors of the wafer relative to a reference value. Position sensing typically requires rotation of the wafer relative to the sensor. Rotation errors are corrected by proper rotation of the wafer support at transfer station 16 . The wafer is then transferred by the second robot 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com