Shifting device, surface installation apparatus, error list generating method

A transfer device and error technology, applied in the direction of manipulators, metal processing, electrical components, etc., can solve the problems of encoder output and actual rotation angle difference, high-precision positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

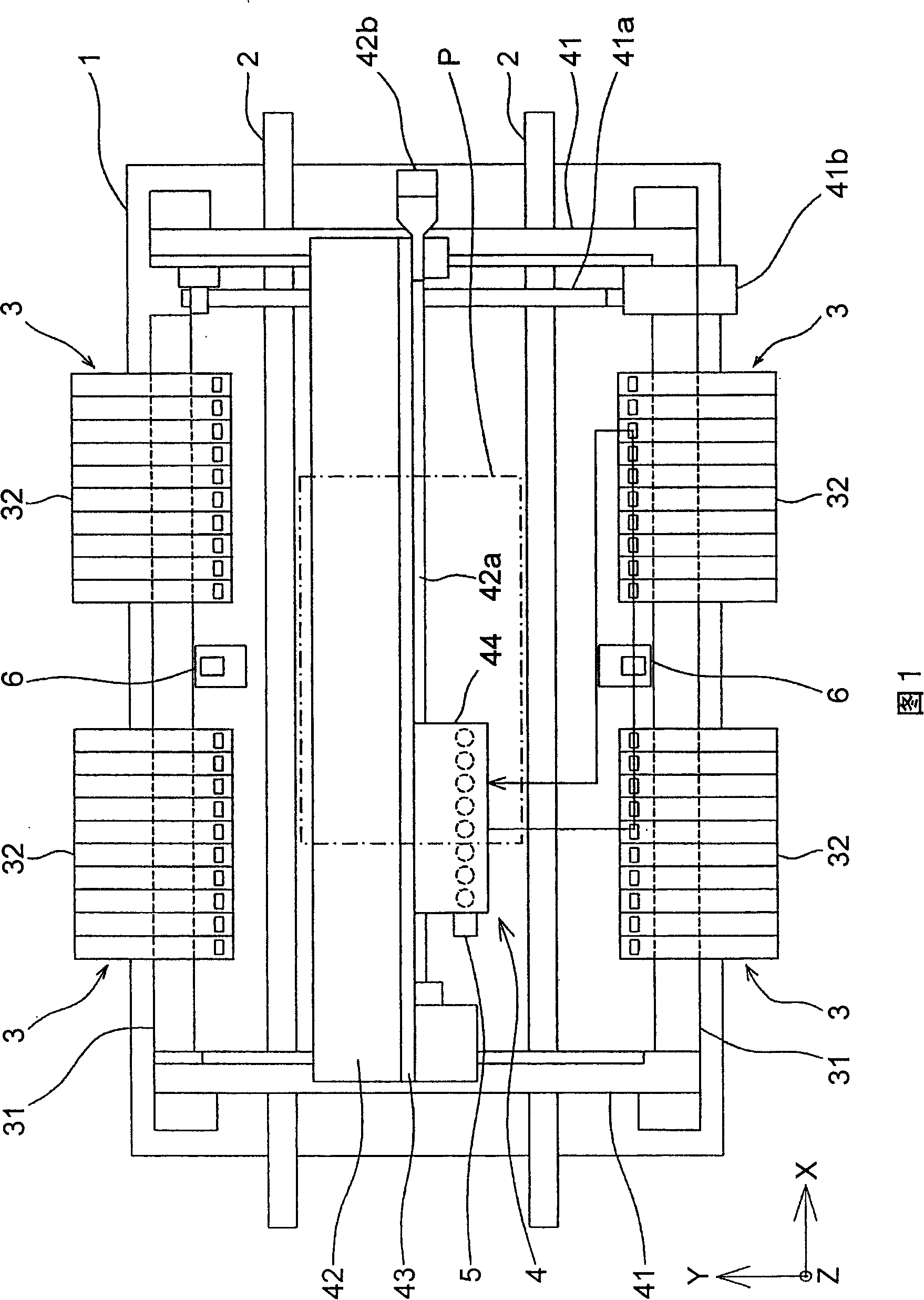

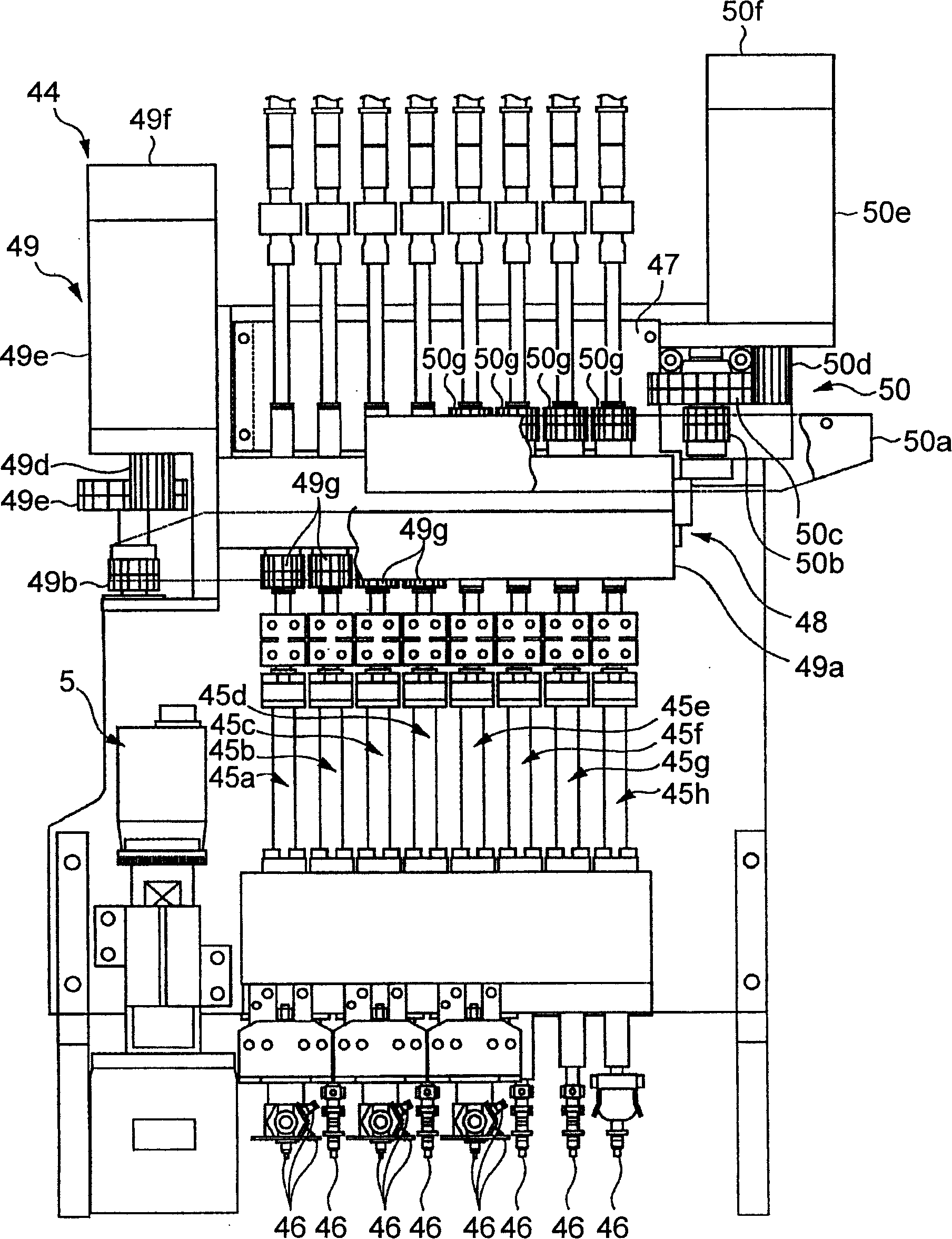

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 is a top view of a surface mounting machine according to an embodiment of the present invention, figure 2 is a side view of the surface mounter of this embodiment, image 3 is the front view of the surface mount head unit of this embodiment, Figure 4 is a block diagram showing the structure of the surface mounter control system of this embodiment.

[0026]The surface mounting machine of this embodiment has a base 1 with a substantially rectangular plane, and a conveyor belt 2 for transporting a printed circuit board P is provided on the base 1 along the longitudinal direction (X-axis direction) of the base 1. On the base 1 located on both sides of the conveyor belt 2, the component supply part 3 for supplying electronic components is provided above the base 1, and the electronic components of the component supply part 3 are transferred to the printe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com