Calculating method for ball center coordinate of non-contact R-test measuring instrument using eddy current displacement sensor

A displacement sensor, non-contact technology, used in computer control, instruments, simulators, etc., can solve the problems affecting measurement accuracy, sensor reading sensitivity is not high, not yet perfect, etc., to avoid measurement error, range and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0038] Structure description of non-contact R-test measuring instrument using eddy current displacement sensor:

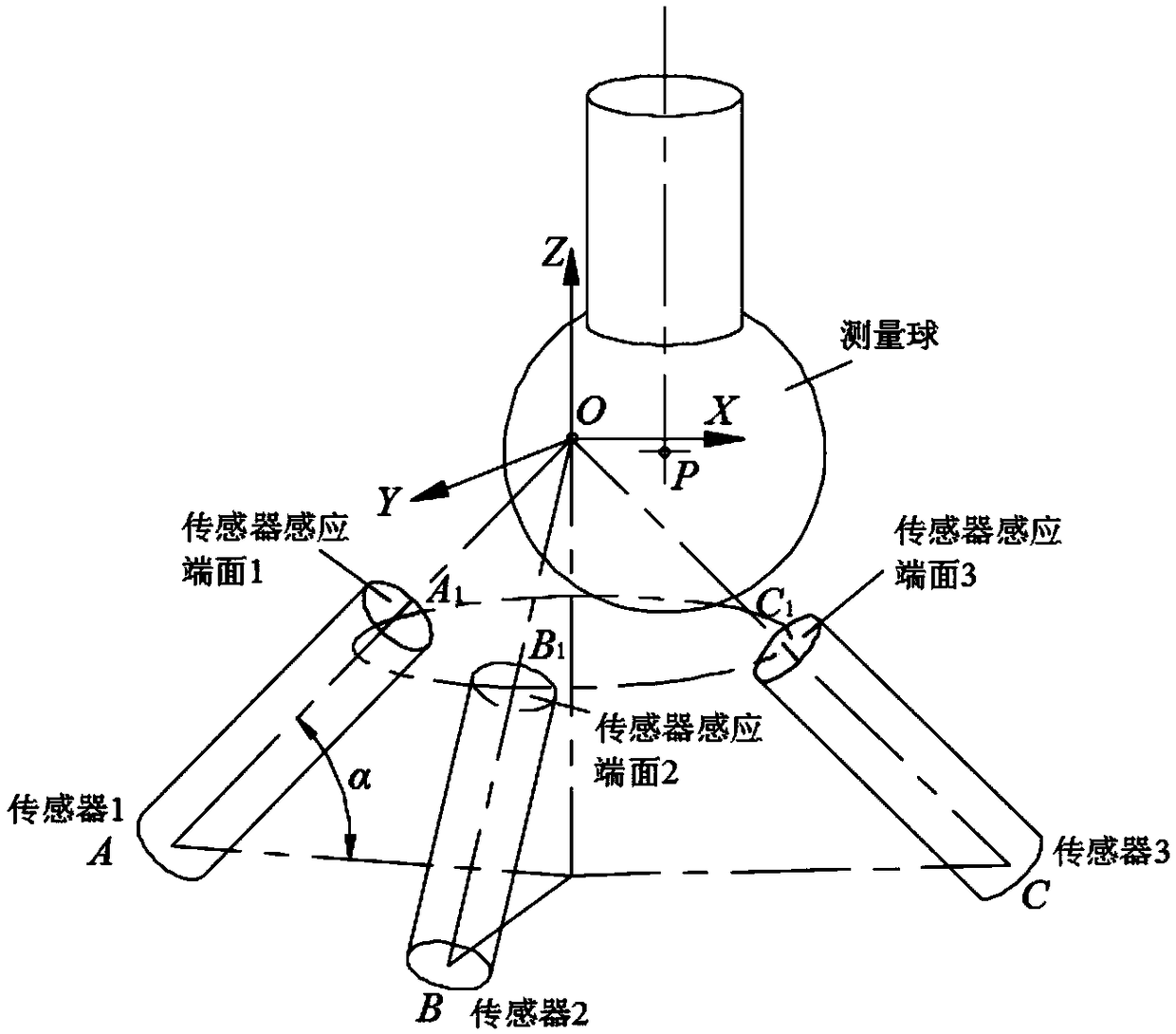

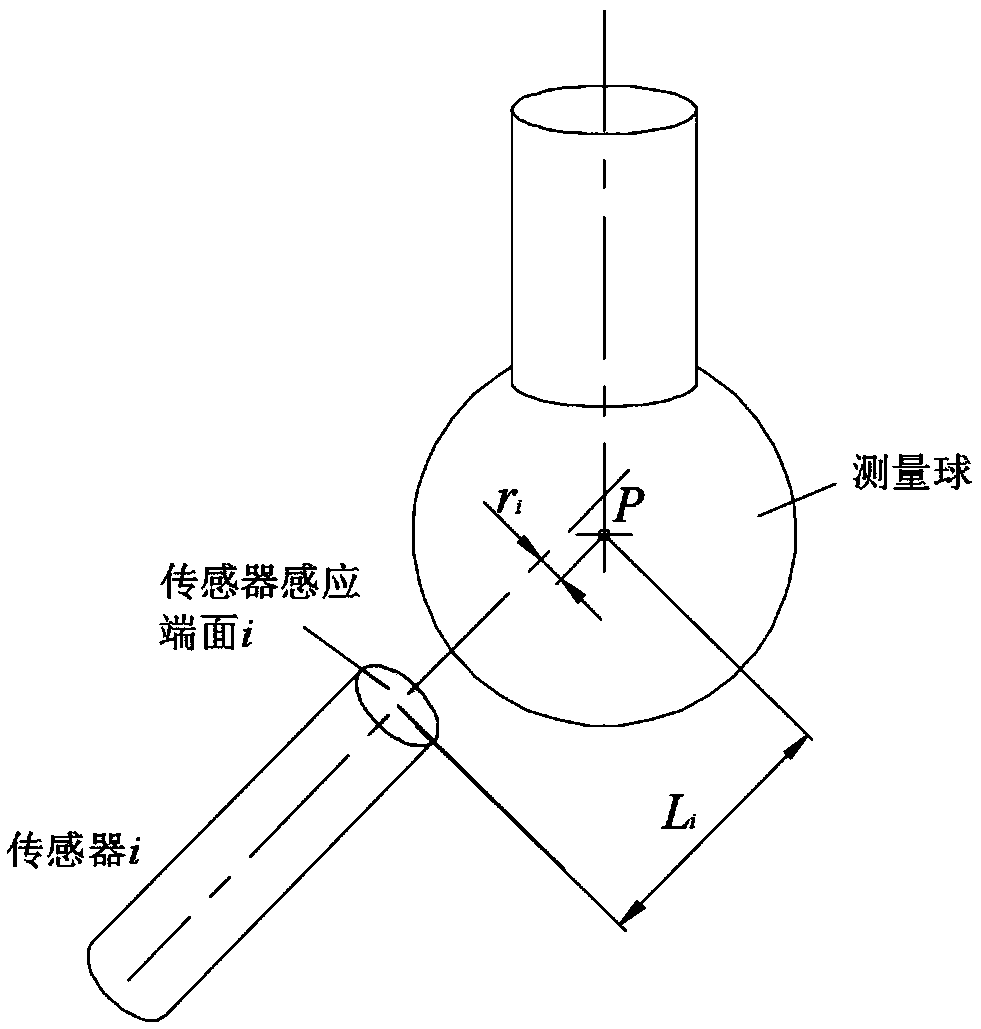

[0039] The structure model of the non-contact R-test measuring instrument using the eddy current displacement sensor is as follows figure 1 As shown, it mainly includes 3 evenly distributed eddy current displacement sensors and a standard measuring ball. According to the shortest distance spatial position relationship between the sensor plane and the measuring ball, the coordinate calculation of the center point P of the measuring ball is performed.

[0040] figure 1 Medium AA 1 , BB 1 , CC 1 Is 3 eddy current displacement sensor axes (A 1 , B 1 , C 1 It is the center point of the sensing plane of the 3 sensors, A, B, C are the center points of the bottom ends of the 3 sensors), the end of the sensor is the radius of R Explore The sensing plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com