Installation error identification method based on rotating shaft integration error measurement value

A technology of comprehensive error and installation error, which is applied in the field of identification of installation error of the rotating shaft based on the comprehensive error measurement value of the rotating shaft, can solve the problems that the rotating shaft is not perfect and the machining accuracy is easily affected by various errors, etc., and achieves strong applicability , The effect of simple measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

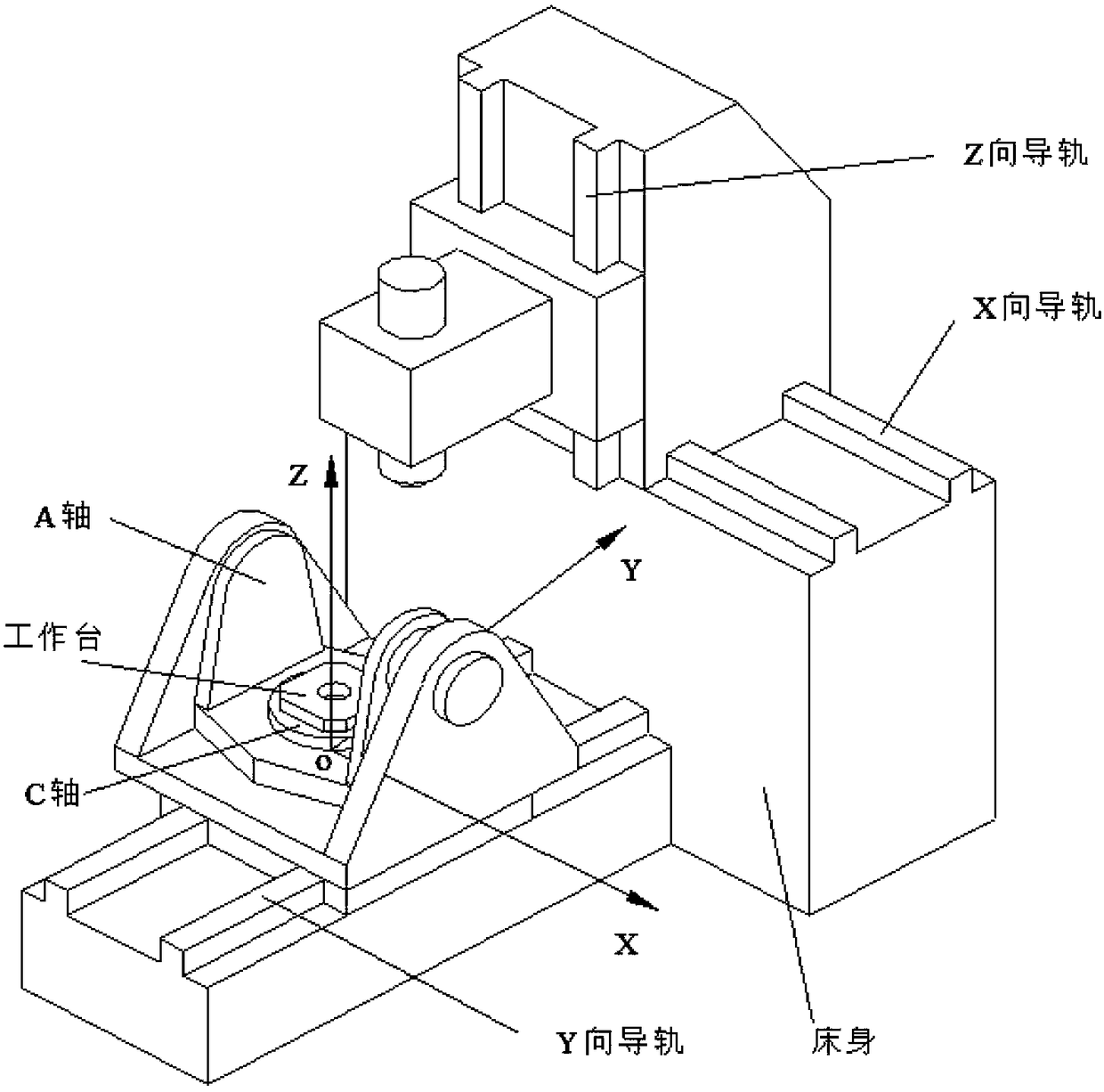

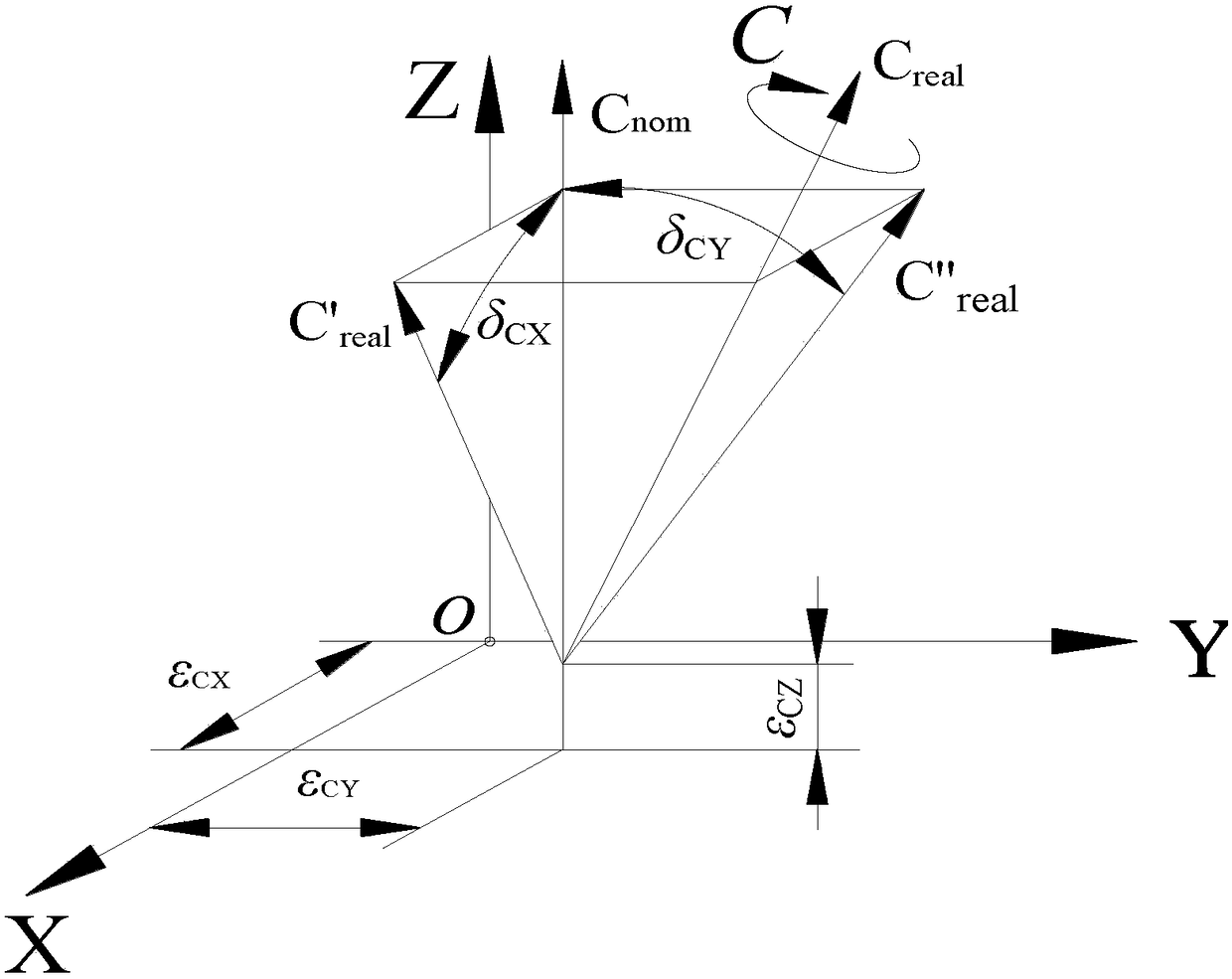

[0131] The C-axis of the HS664RT five-axis machining center of FIDIA Company is used to identify the installation error, and the measuring equipment is the R-test measuring instrument of IBS Company; the specific implementation steps and related measurement data and test results are as follows:

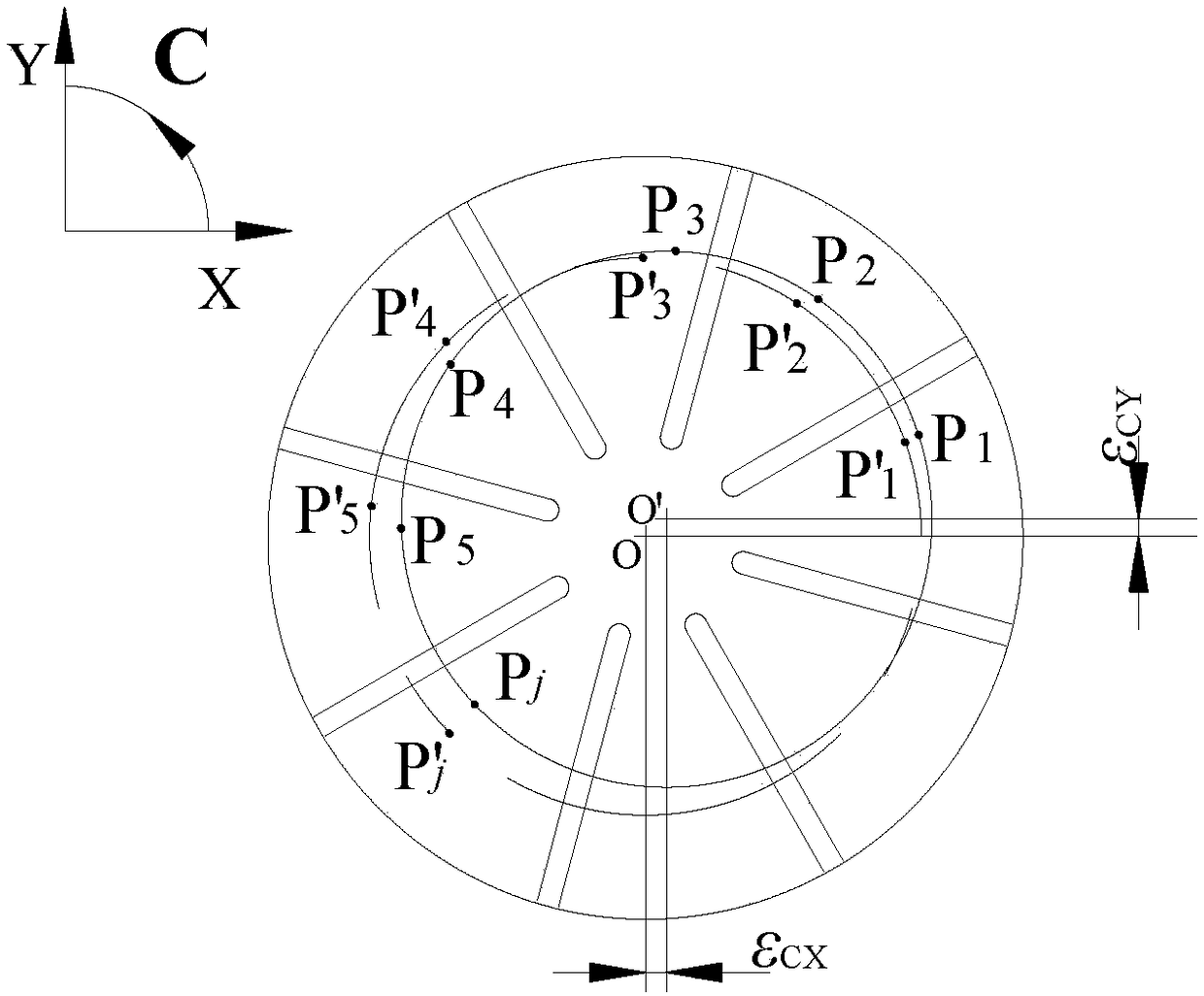

[0132] (1) The installation and commissioning of the R-test measuring instrument and the establishment of a measuring coordinate system, the measuring point corresponding to the measuring instrument P(x 0 ,y 0 ,z 0 ) in the measuring coordinate system is (0, 254, 100), the unit is mm;

[0133] (2) Prepare the measurement program, the test range is C-axis 0°~360°, every time the C-axis rotates 30°, pause for 3 seconds to perform a comprehensive error measurement of the measurement point, and measure once clockwise and counterclockwise;

[0134] (3) When measuring, turn on the RTCP function of the machine tool, and the comprehensive error measurement results are shown in Table 1;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com