Laser interference principle-based precise main shaft rotation precision detecting device and method

A technology of laser interference and rotation accuracy, which is applied in the direction of measuring/indicating equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unfavorable synchronous analysis, great difficulty in sensor installation, high sensor angle requirements, etc., to achieve reduction Save maintenance requirements, test work is simple and convenient, and measure accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in further detail below in conjunction with accompanying drawing:

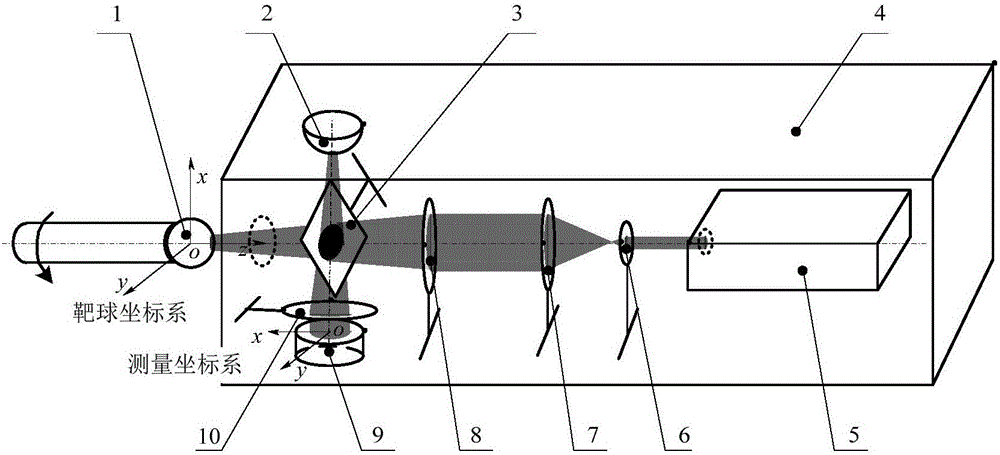

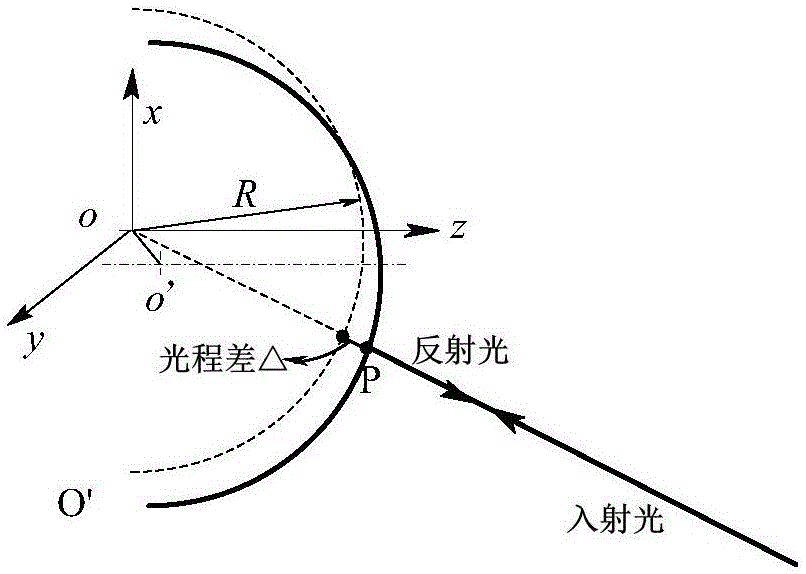

[0045] see figure 1 , the present invention is based on the principle of laser interference precision spindle rotation accuracy detection device, including a box 4 and a target ball 1 . The box body 4 is fixed in space, and a laser generation and interference test system is installed in the box body 4; the laser emission system includes a laser source 5, which can generate stable monochromatic laser light, and the interference test system includes a first beam expander lens 6, a second Two beam expander lenses 7, the first convergent lens 8, half-transparent mirror 3, reference ball 2, the second convergent lens 10, CCD camera 9; the first beam expander lens 6, the second beam expander lens 7 to the laser source 5 The generated laser beam has the effect of collimating and expanding the beam; the first converging lens 8 converges the adjusted laser beam, and converts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com