Vane displacement error detection device of multi-vane collimator

A multi-leaf collimator, displacement error technology, applied in the directions of X-ray/γ-ray/particle irradiation therapy, etc., can solve the problem of inability to know the error value, achieve convenient operation, solve the problem that the hysteresis value cannot be accurately measured, and the structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

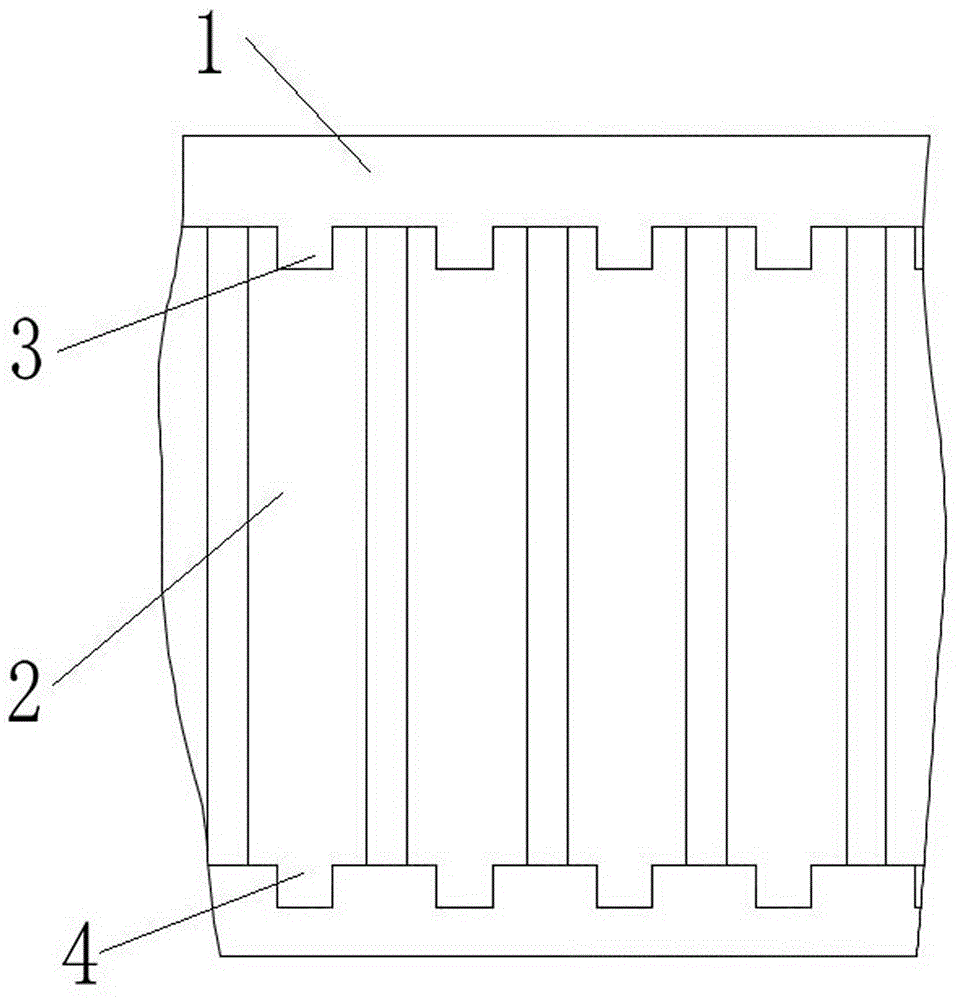

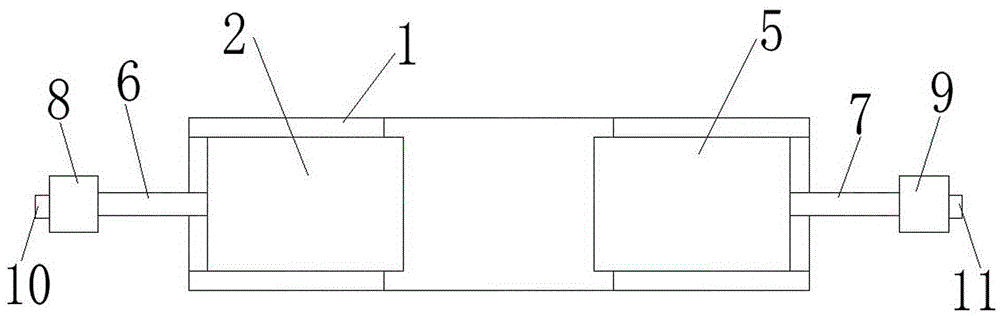

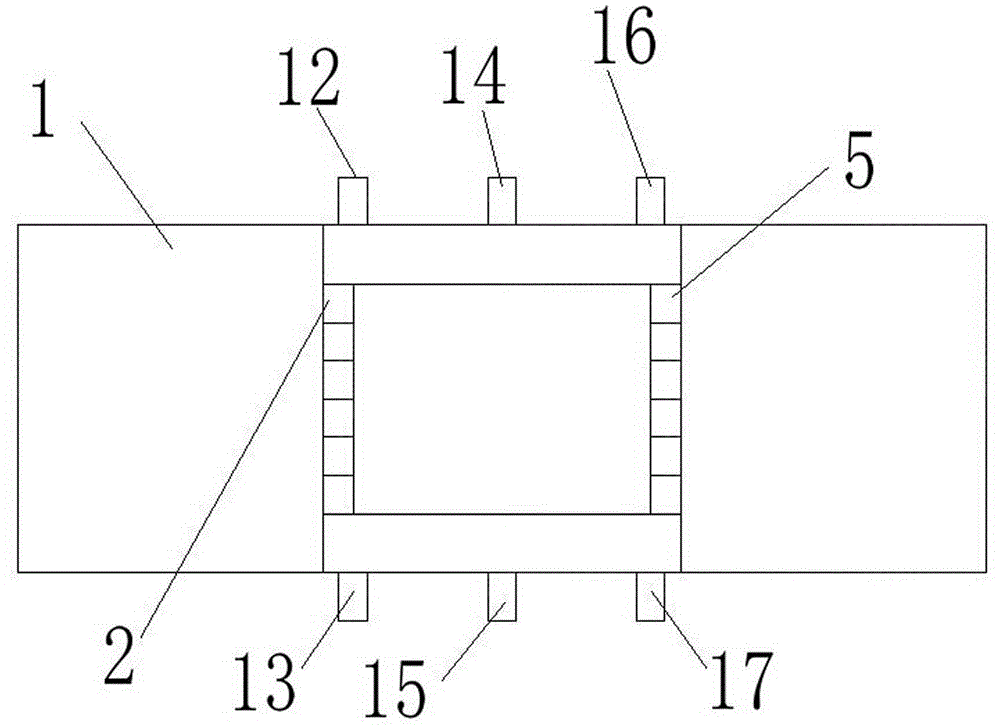

[0014] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

[0015] The multi-leaf collimator blade displacement error detection device includes a housing 1, a number of left blades 2 and right blades 5 that are slidably installed on the left side and right side of the housing 1 through a sliding device, and are respectively screwed on each left side. Lead screw I 6 and lead screw II 7 on blade 2 and right blade 5, motor I 8 and motor II 9 fixed on the left and right sides of housing 1, the heads of lead screw I 6 and lead screw II 7 are respectively It is connected to the output shafts of motor I 8 and motor II 9, the encoder I 10 and encoder II 11 are respectively connected to the tail ends of the output shafts of motor I 8 and motor II 9, and the infrared laser in the middle of the rear end of the housing 1 The transmitter II 14 of the sensor, the infrared laser sensor receiver II 15 is installed in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com