Patents

Literature

41results about How to "Facilitate catalytic conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and systems for pressure swing regeneration for hydrogen generation

InactiveUS6942719B2Promote catalytic reformingEasy to shiftOther chemical processesHydrogen separation using solid contactSteam reformingHydrogen

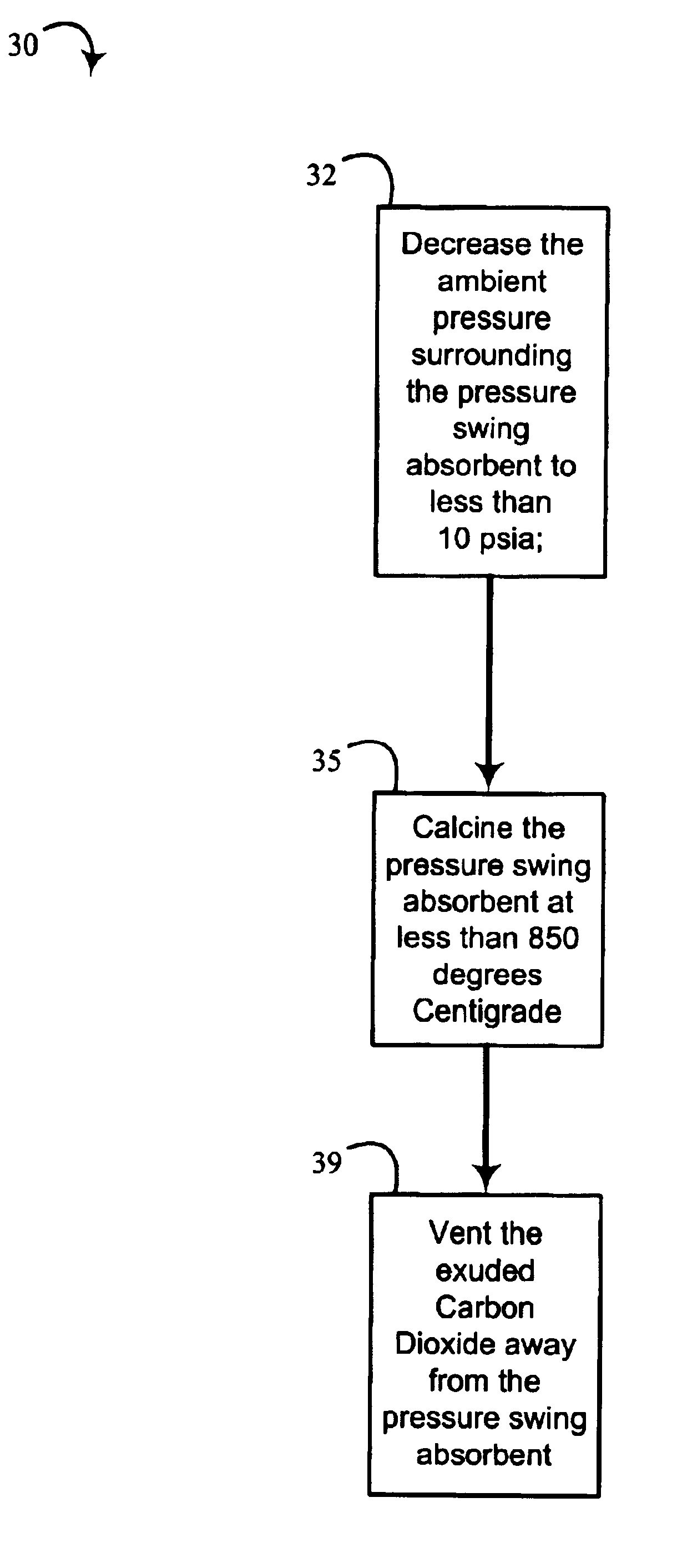

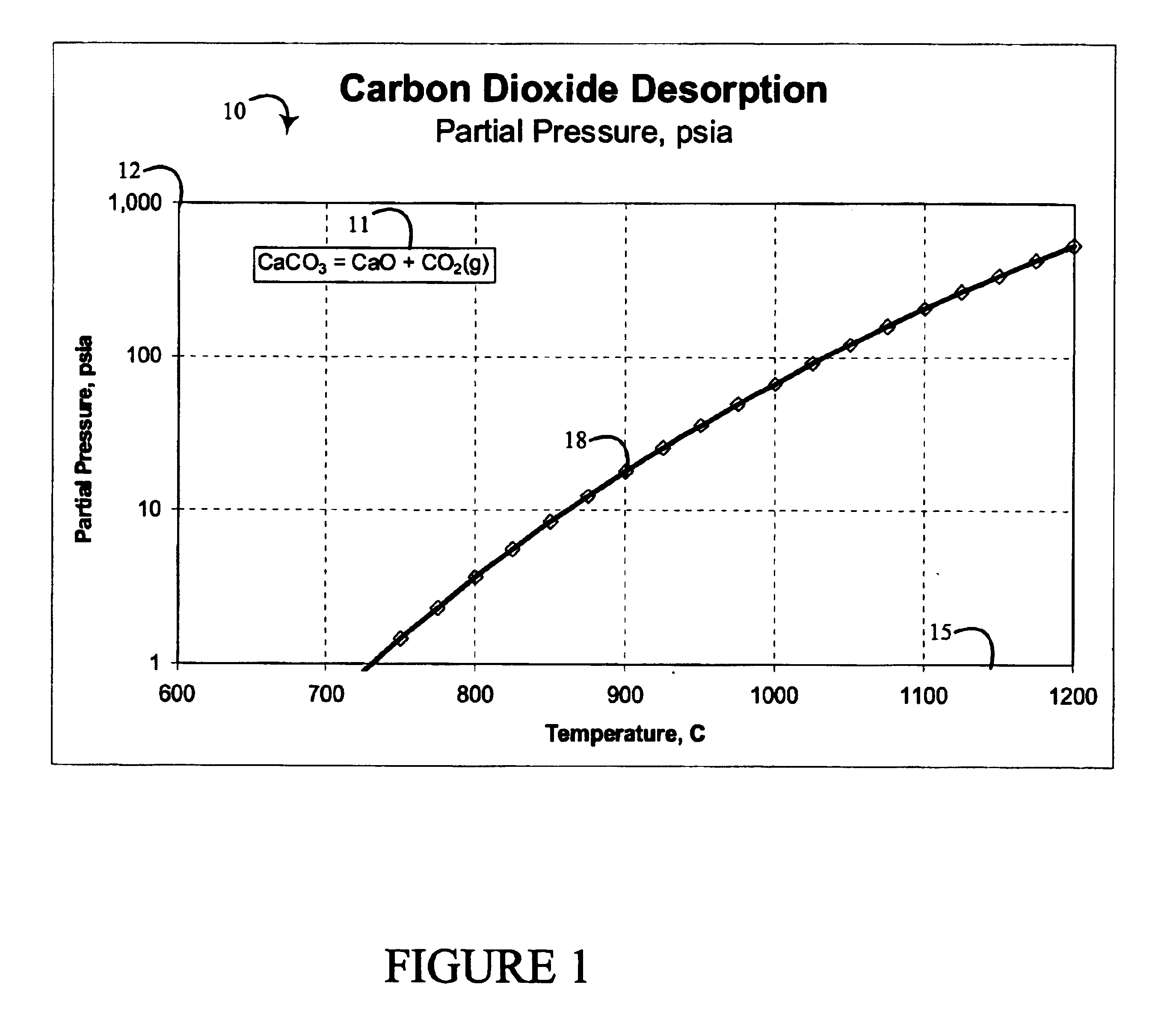

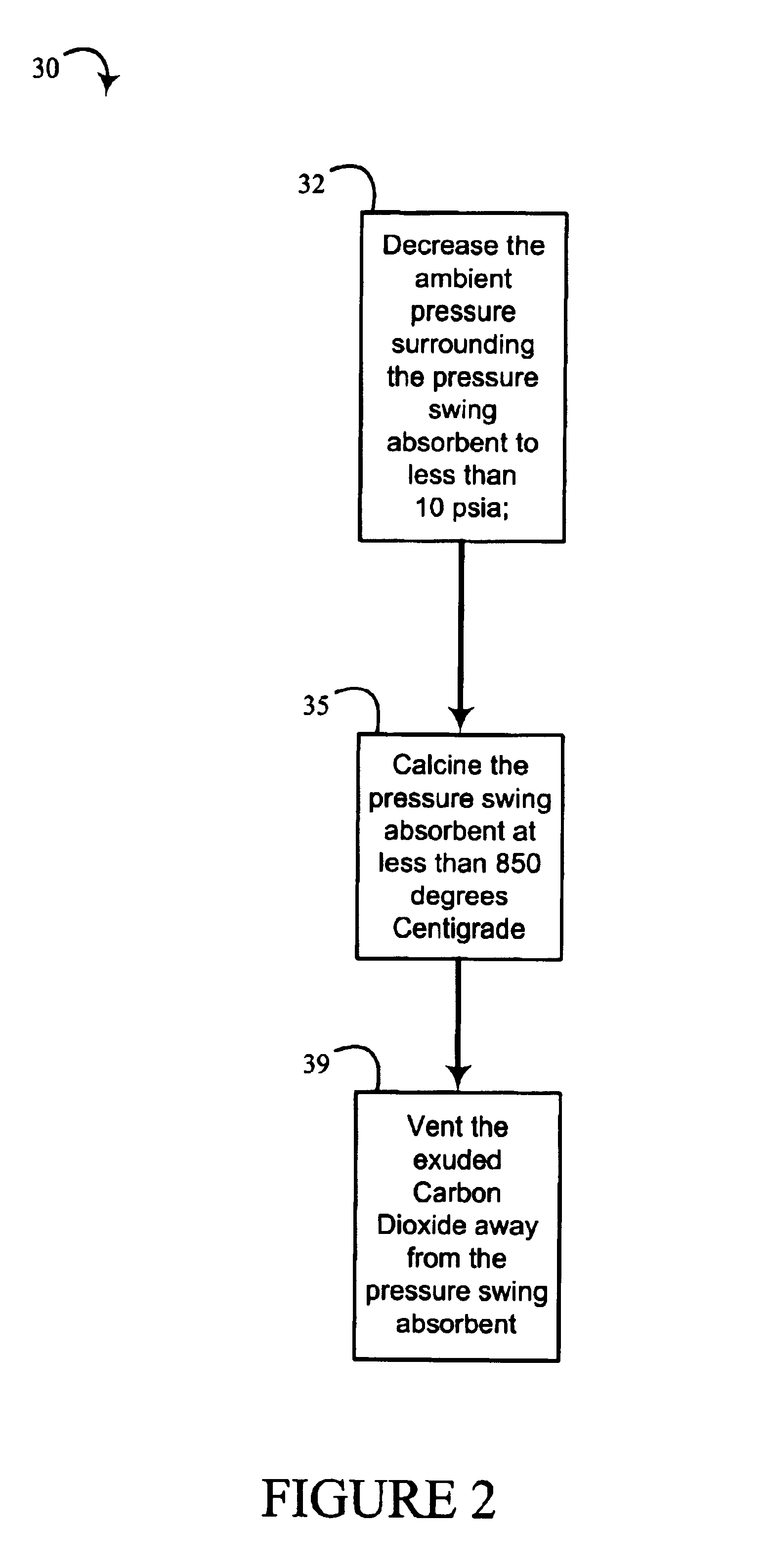

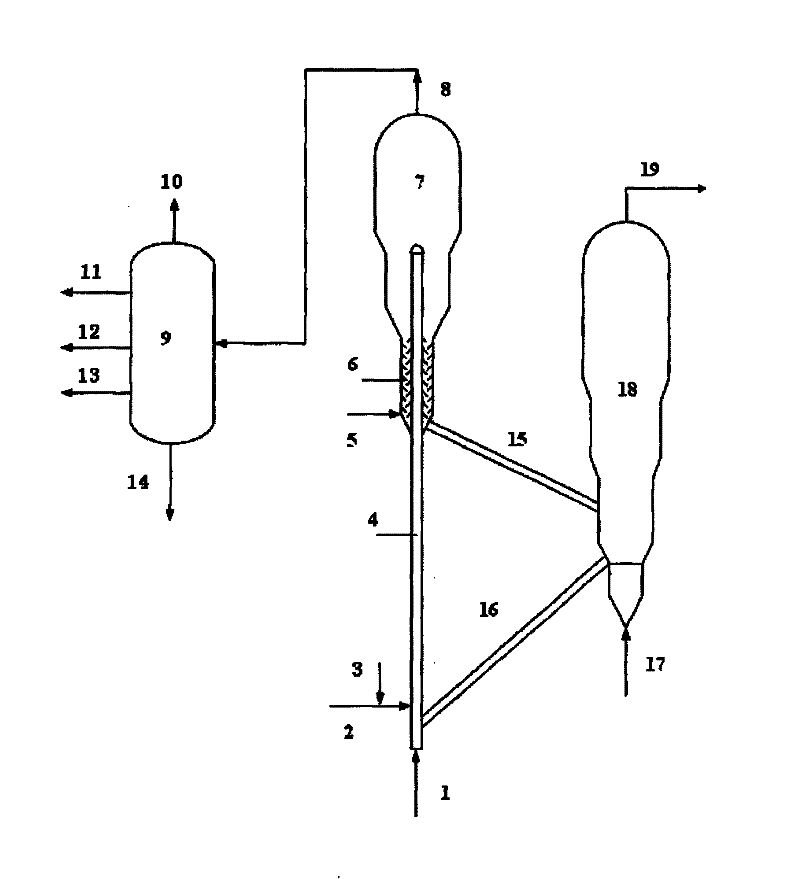

Methods and systems for pressure swing absorption for hydrogen generation are presented. In one embodiment, a method includes absorbing at least one oxide of carbon with a pressure swing absorber from a steam reformation of methane. The steam reformation may occur at an ambient pressure in excess of 300 psia and at an ambient temperature in excess of 600° centigrade. The steam reformation of methane produces a stream of product gas. The steam reformation of methane is interrupted allowing the regenerating of the pressure swing absorber at an ambient pressure of less than 10 psia and at an ambient temperature sufficient to calcine the pressure swing absorber to exude carbon dioxide.

Owner:GAS TECH INST +1

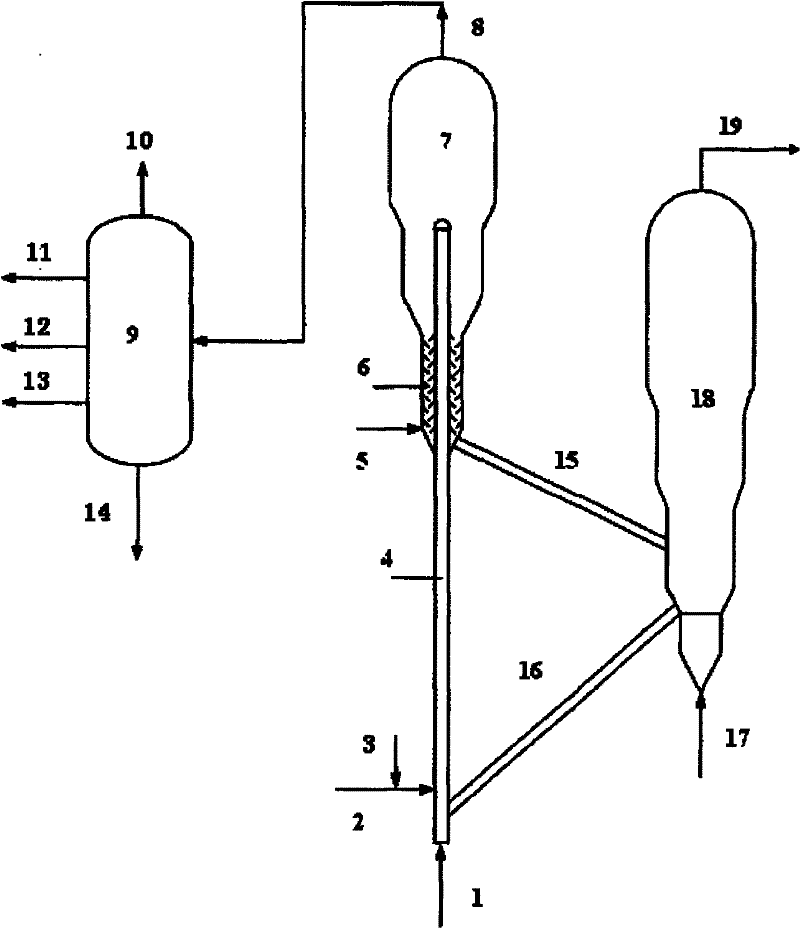

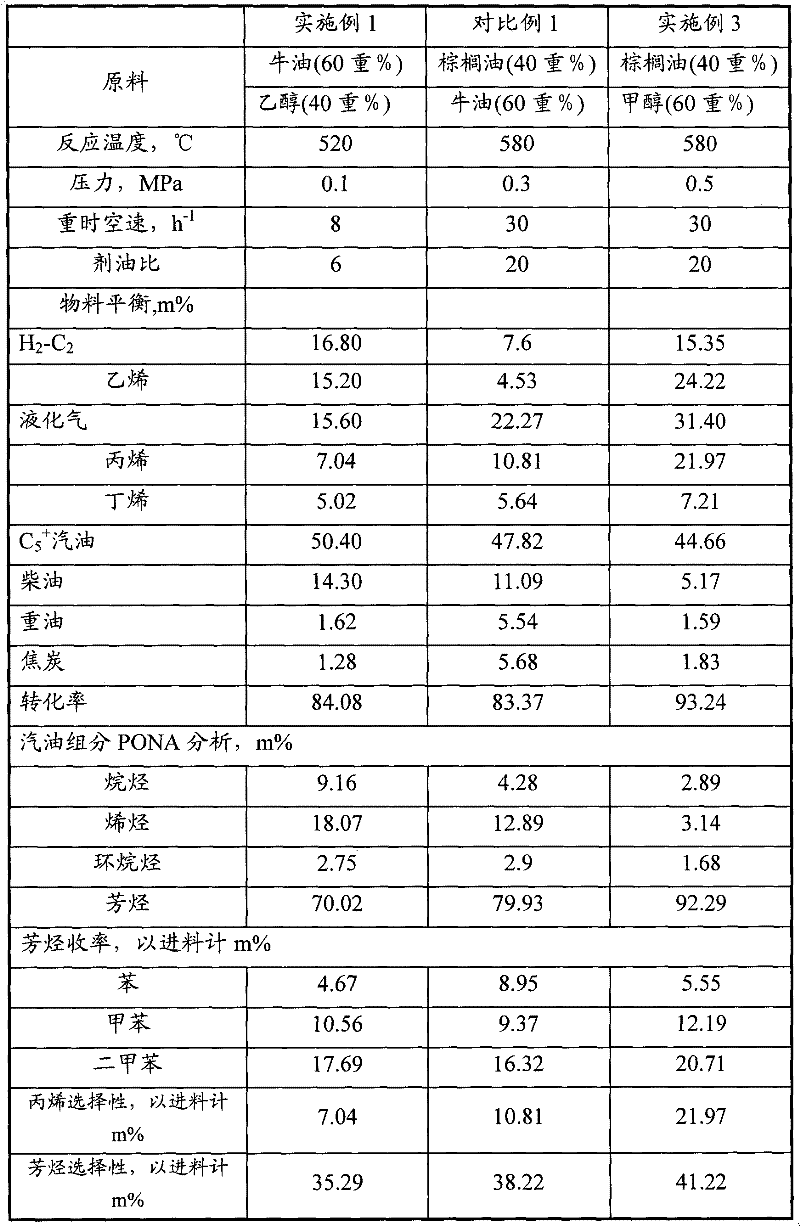

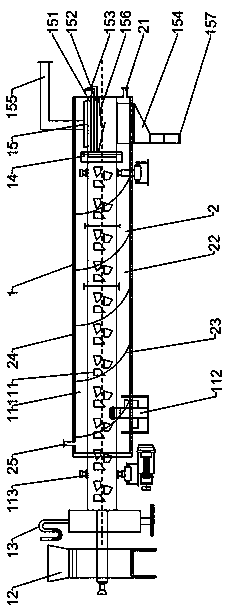

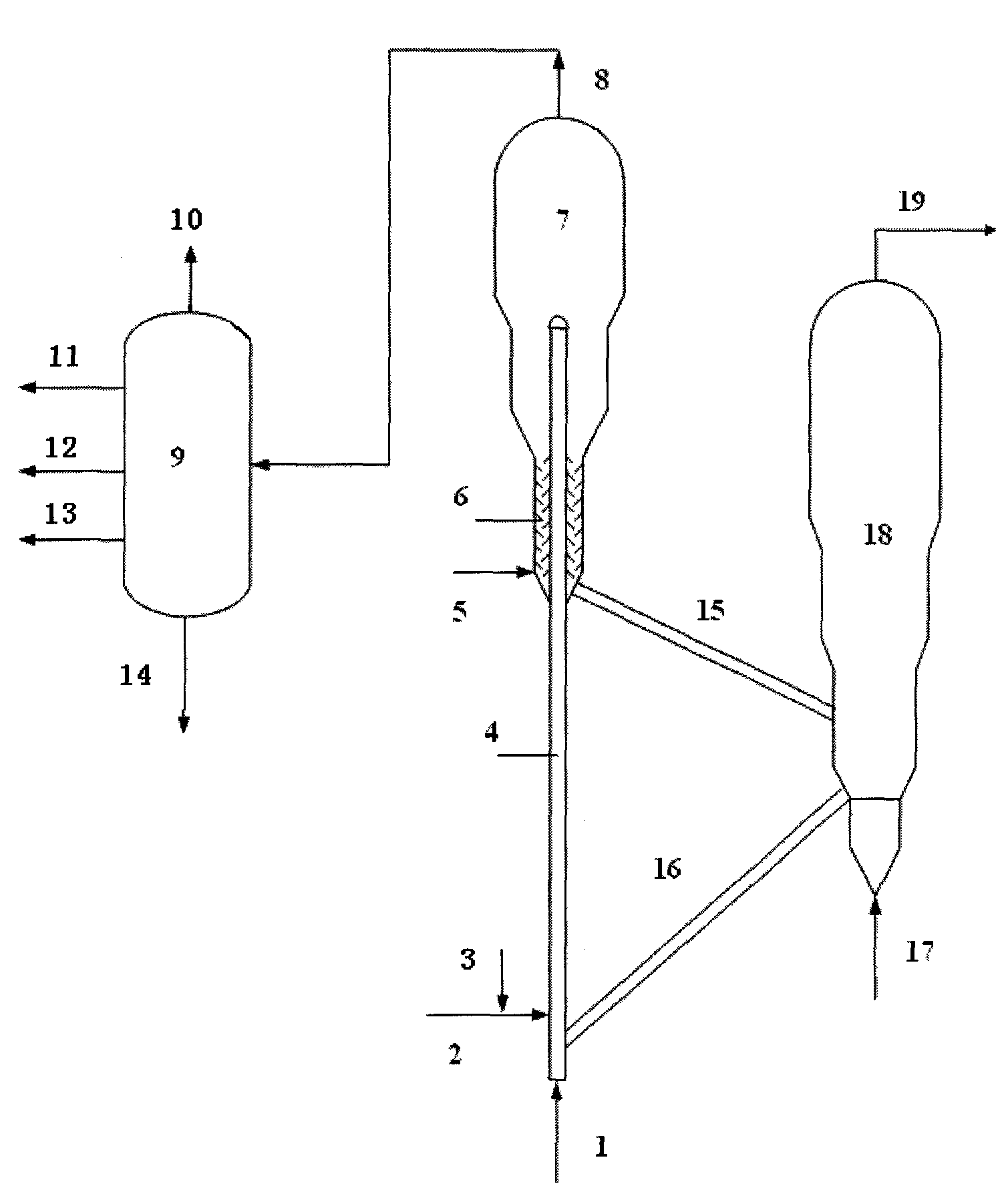

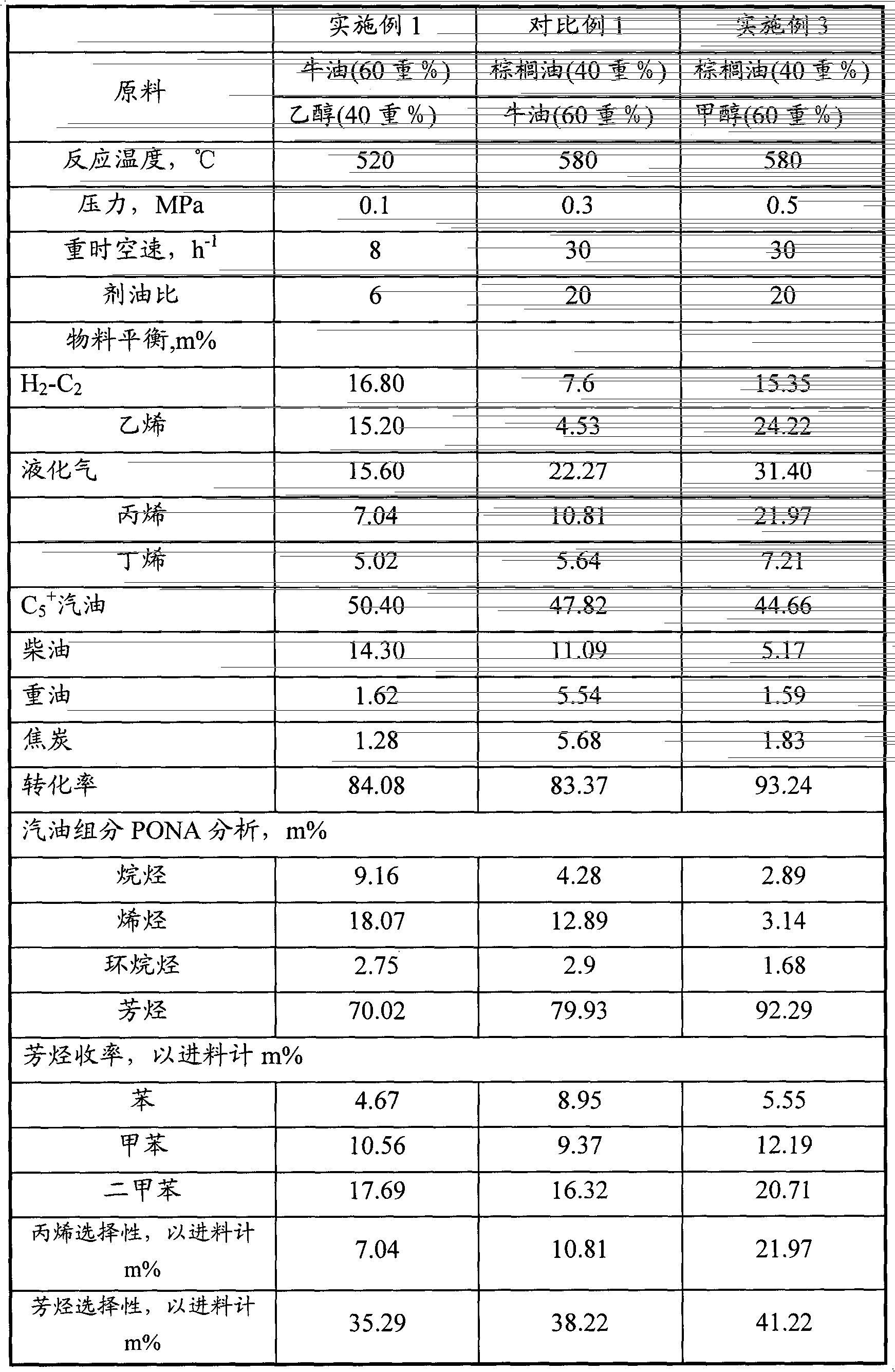

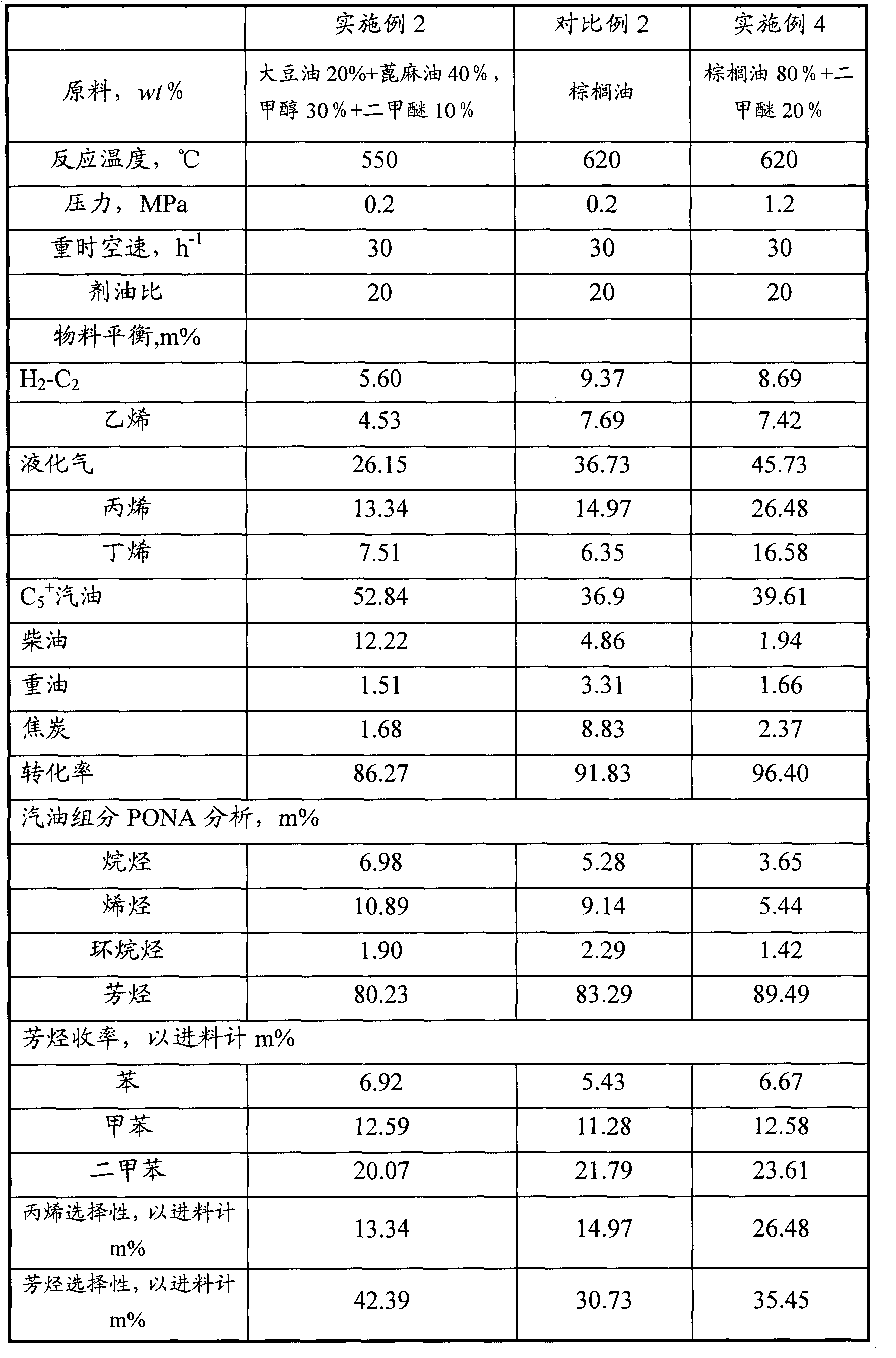

Preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oils and oxygenated chemical

ActiveCN102206502AFacilitate catalytic conversionReduce energy consumptionHydrocarbon purification/separationLiquid hydrocarbon mixture productionOil and greaseReaction temperature

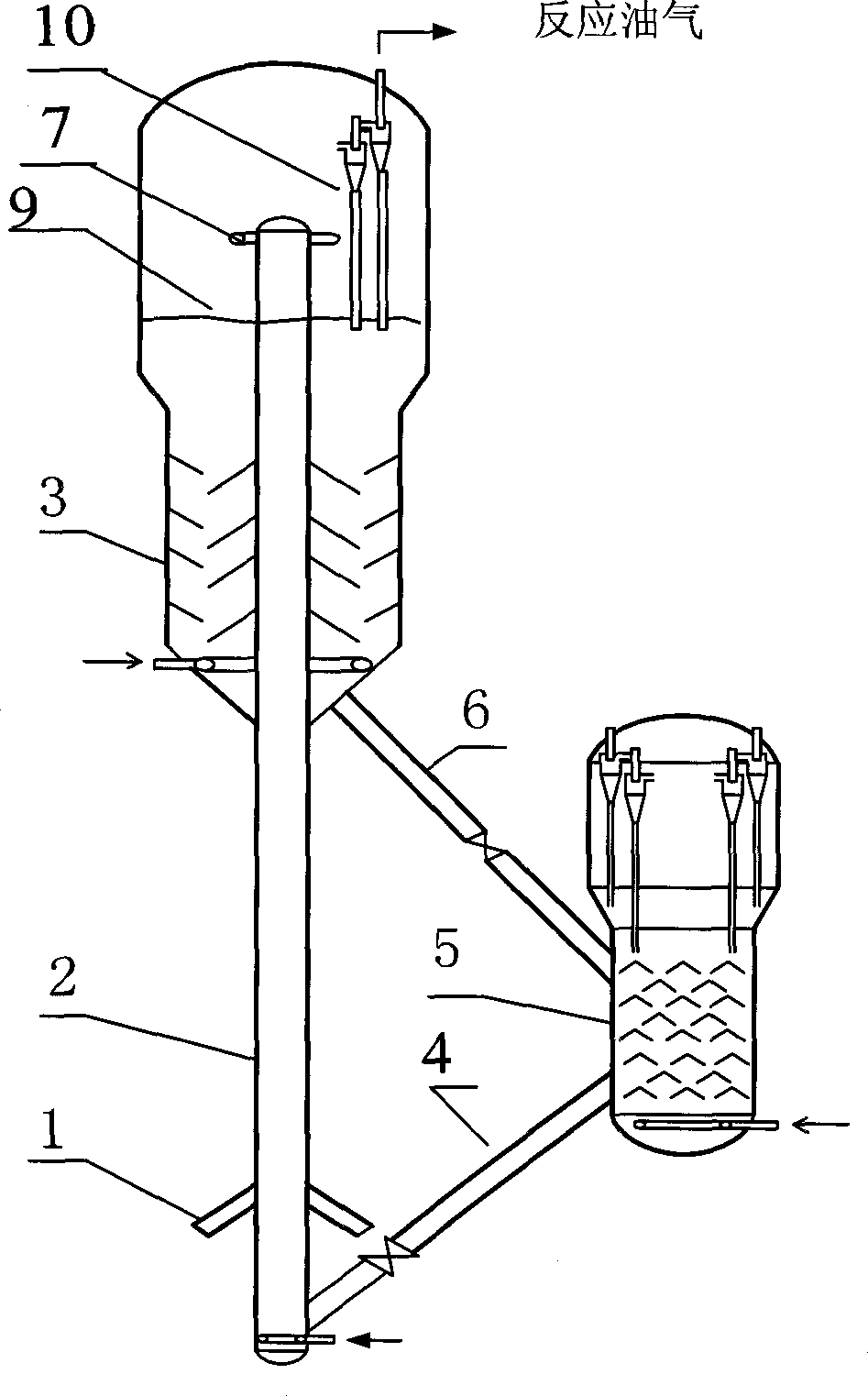

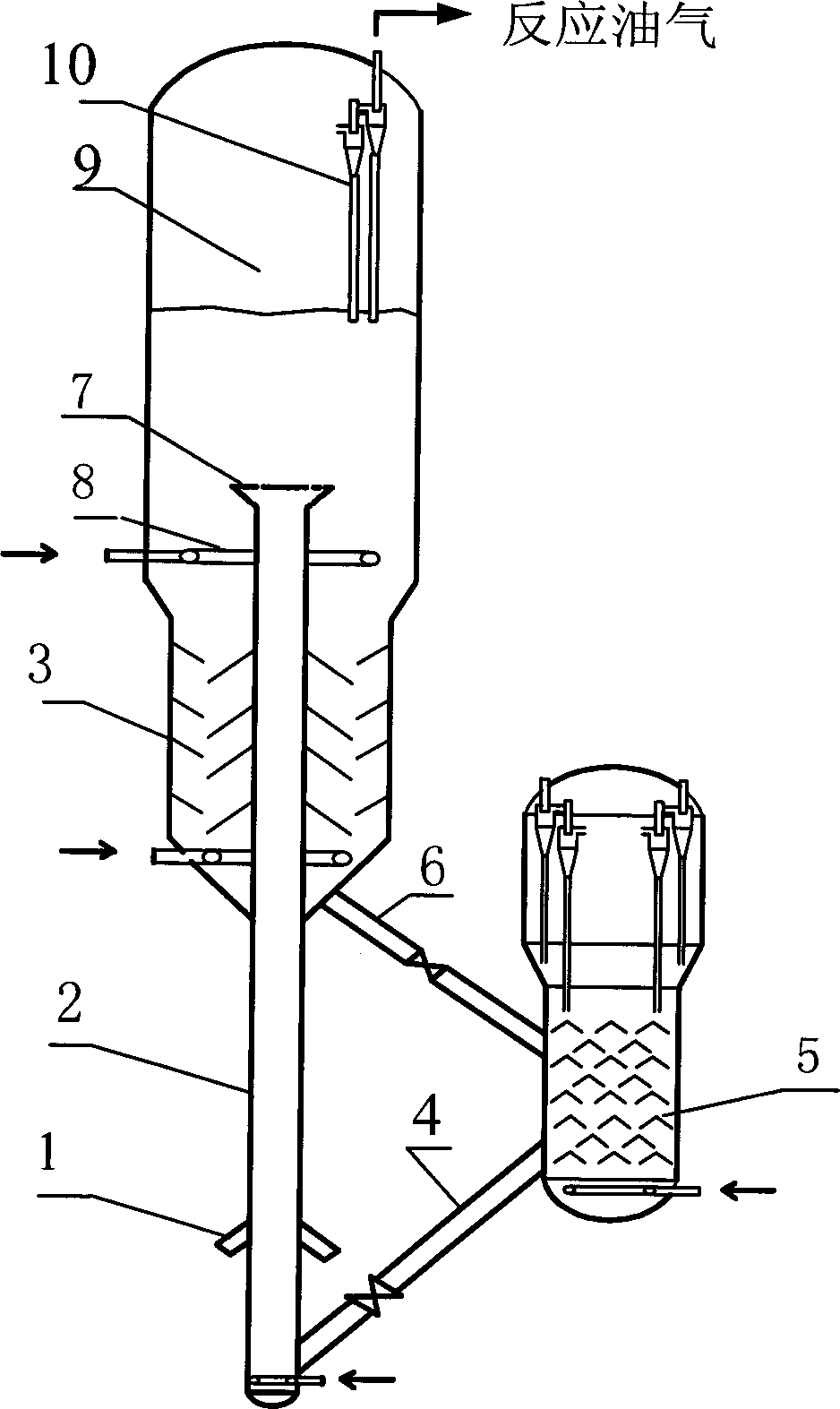

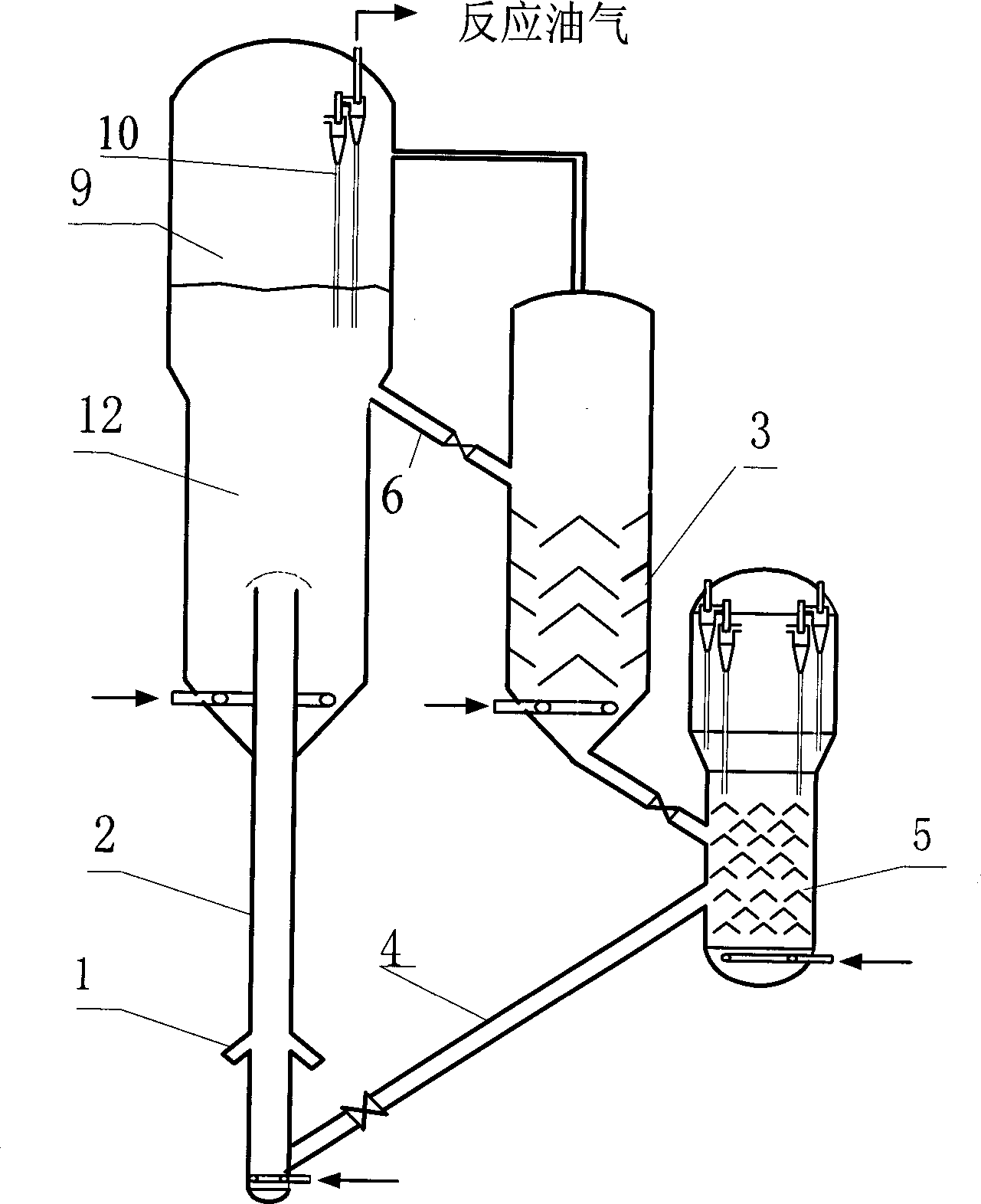

A preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oil and an oxygenated chemical is characterized by: introducing raw materials such as the plant oil and the oxygenated chemical into a catalytic cracking reactor; carrying out a catalytic conversion reaction through contacting with a catalytic cracking catalyst in the reactor with an operating temperature of 500 to 670 DEG C, an operating pressure of 0.1 to 5.0 MPa, a weight hourly space velocity of 0.1 to 100 h<-1> and an agent-oil ratio of 1 to 50; separating a reaction oil gas from the spent catalyst when the reaction is finished; recycling the separated spent catalyst after stripping, burning and regenerating; obtaining fractions such as a liquefied gas, gasoline and the like through fractionating the reaction oil gas and obtaining the low-carbon olefins through a manner that the liquefied gas enters a gas separating system; and obtaining the aromatic hydrocarbon product through carrying out a further aromatic extraction on the gasoline fraction. The method provided by the present invention allows the reaction temperature to be controlled through co-processing the plant oil and the oxygenated chemical, the selectivity of the target product gasoline to be improved, and energy consumption to be reduced. In terms of a reaction apparatus, equipment flow is simplified because heat exchangers which are arranged for removing reaction heat can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

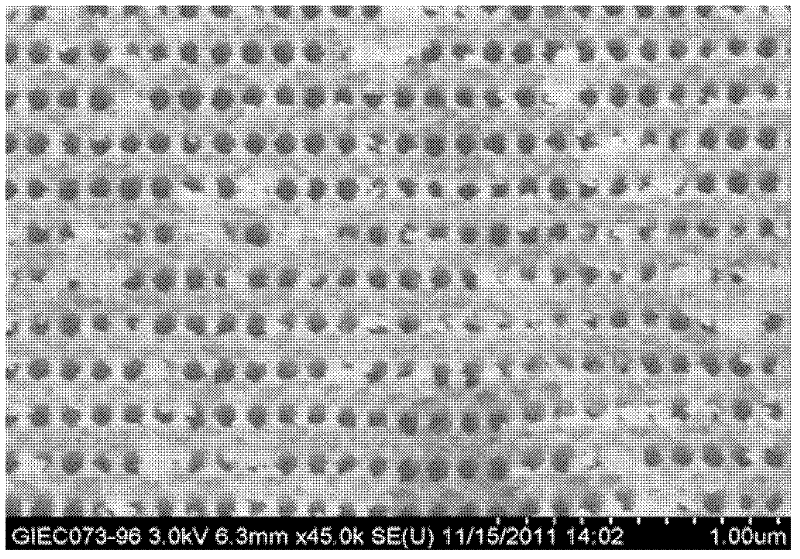

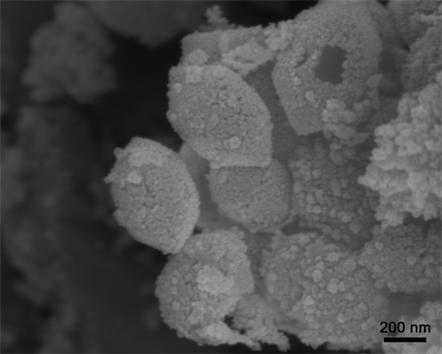

Application of three-dimensional ordered macro-porous perovskite type oxide in preparing hydrogen through carbonic fuel chemical chain

InactiveCN102515096AStable structureIncrease contact areaHydrogenBulk chemical productionWater vaporDecomposition

The invention provides an application of a three-dimensional ordered macro-porous perovskite type oxide which is used as an oxygen carrier for preparing hydrogen through a carbonic fuel chemical chain. The three-dimensional ordered macro-porous perovskite type oxide has the characteristics of the perovskite type oxide and has a three-dimensional ordered macro-porous structure of an inverse opal structure. The three-dimensional ordered macro-porous perovskite type oxide is used as an oxygen carrier for preparing the hydrogen through the carbonic fuel chemical chain and has a general formula of ABO3, wherein A is rare-earth metal and B is transition metal. The three-dimensional ordered macro-porous structured perovskite structure has stable properties and longer service life; pore channels and specific surface area are bigger; during a contact process of the oxygen carrier and a carbonic fuel, much more lattice oxygen for participating in reaction can be supplied; the contact of the oxygen carrier and the carbonic fuel can be boosted; the specific surface area of the oxygen carrier can be increased by abundant pore channels; catalytic conversion between small particles and gas molecules is boosted; the three-dimensional ordered macro-porous perovskite type oxide has higher reaction activity in chemical chain combustion and steam pyrolytic decomposition; and compared with the conventional metal oxygen carrier, the three-dimensional ordered macro-porous perovskite type oxide has higher reaction activity and hydrogen yield.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Catalyst with high carbon dioxide hydrogenation methanation performance, method for preparing catalyst and application thereof

ActiveCN106268858AEvenly distributedFully exposedHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsMethanationActive component

The invention discloses a catalyst with high carbon dioxide hydrogenation methanation performance. The catalyst comprises, by weight, 45-60% of main active components, 5-15% of precious metal active components, 2-8% of structural promoters, 5-15% of rare earth promoters and the balance vectors. The catalyst has the advantages that the catalyst is excellent in carbon dioxide methanation reaction performance, and accordingly hydrogen components in methanation products can be effectively reduced.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

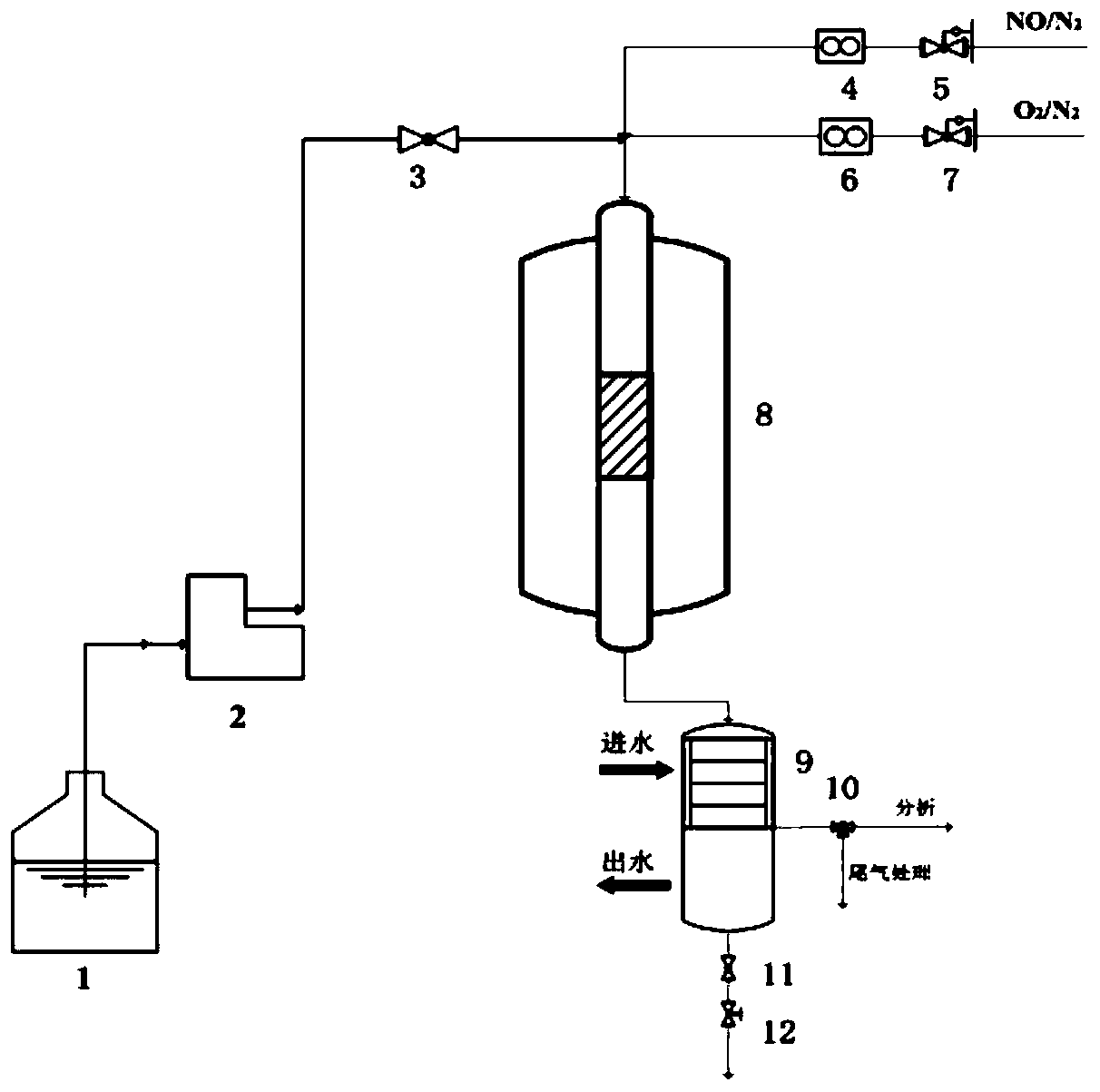

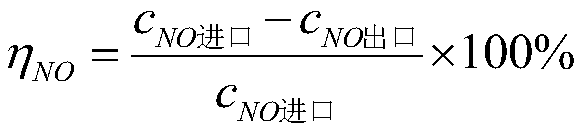

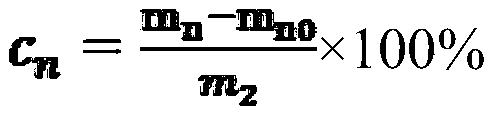

Low-temperature flue gas denitration agent and preparation method and application thereof

ActiveCN110385023ASolve the technical bottleneck of denitrificationImprove denitrification efficiencyGas treatmentDispersed particle separationFiberSodium Bentonite

The invention provides a low-temperature flue gas denitration agent, and belongs to the technical field of denitration purification of flue gas. The low-temperature flue gas denitration agent is prepared from the components in parts by weight: 30-80 parts of active components, 0.1-10 parts of an additive, 1-20 parts of a carbon source, and 2-30 parts of a binder; the active components are one or more of CaCO3, CaO and Ca(OH)2; the additive is one or more of Fe2O3, MnO2, CuO and Co2O3; the carbon source is one or more of activated carbon, an activated carbon fiber, pulverized coal, fly ash, flying ash and a biomass fiber; and the binder is one or more of kaolin, bentonite, gypsum and cement. The invention further provides a preparation method of the denitration agent. The denitration agentis low in raw material cost, good in denitration effect and high in denitration capacity, and the using temperature can be decreased to room temperature. The denitration agent is matched with a dry moving bed denitration technology or a fixed bed dry denitration technology, and thus the denitration and dust removal effects are achieved in the application process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Pyrolysis, carbonization and catalysis integrated method

ActiveCN111218291ALow costHigh activityCatalyst activation/preparationIndirect heating destructive distillationPtru catalystFlue gas

The invention discloses a pyrolysis, carbonization and catalysis integrated method, and belongs to the field of biomass pyrolysis. The invention aims to solve the problems of high energy consumption,high cost and low energy utilization rate of an existing method. The pyrolysis, carbonization and catalysis integrated method comprises five processes of sealed feeding, uniform distribution, continuous pyrolysis, tar catalysis and flue gas recycling. Biomass is used as a raw material, feeding and uniform distribution of the processed raw material are realized under a sealed condition, a pyrolyticreaction is carried out, and a pyrolytic oil-gas mixture and biochar are obtained after two main processes of pyrolytic carbonization and carbon-gas separation in sequence; a pyrolysis oil-gas mixture is subjected to a tar catalytic process in a catalytic chamber integrated with a pyrolysis furnace, part of cured biochar is prepared into a new catalyst for being continuously used, and the processes are subjected to stepped heat supply by utilizing waste heat of reflux flue gas. The nickel-based biochar catalyst is high in activity, good in stability, low in preparation cost, environmentally friendly and efficient.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

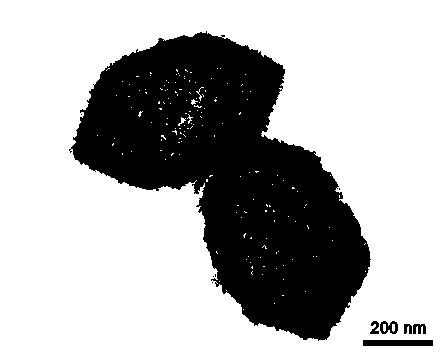

Lithium-sulfur battery positive electrode material and preparation method thereof

PendingCN111211312ARich mesostructureStrong chemical adsorption is goodCell electrodesLi-accumulatorsLithium–sulfur batteryLithium sulfur

The invention provides a lithium-sulfur battery positive electrode material which comprises a hollow positive electrode carrier material, namely cobalt-iron double hydroxide and sulfur particles filled in the carrier material. The preparation method comprises the following steps: preparing a precursor Fe-MOFs material through a solvothermal method, and then drying the prepared Fe-MOFs material; dispersing the Fe-MOFs material in an absolute ethyl alcohol solution, dissolving a cobalt source and urea in deionized water, mixing the two solutions, and heating in a water bath for a certain time toobtain a Co-Fe LDH material; and compounding nano sulfur with the prepared Co-Fe LDH material to obtain a Co-Fe LDH@S composite positive electrode material. According to the preparation method of a hollow-structure lithium-sulfur battery positive electrode carrier Co-Fe LDH material, the prepared Co-Fe LDH@S composite positive electrode material can be directly applied to the field of energy storage materials, and has a wide application prospect.

Owner:HENAN UNIV OF SCI & TECH

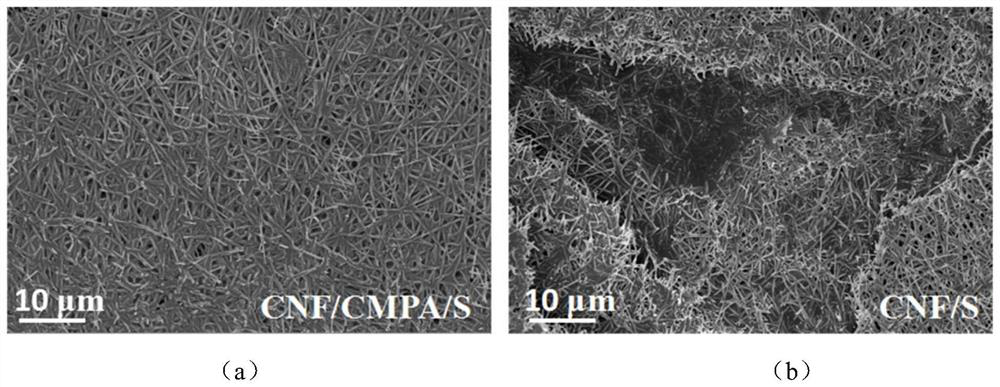

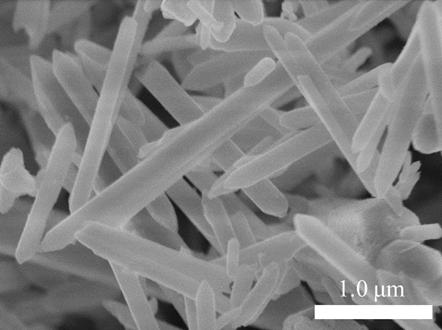

Nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material, lithium battery diaphragm, preparation method of lithium battery diaphragm, lithium-sulfur battery and electric equipment

ActiveCN111285348AImprove adsorption capacityStop the spreadSecondary cellsCarbon preparation/purificationCarbon compositesElectrical battery

The invention provides a nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material, a lithium battery diaphragm, a preparation method of the lithium batterydiaphragm, a lithium-sulfur battery and electric equipment. A preparation method of the nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material comprises the following steps: mixing raw materials including an iron source, a nitrogen-containing organic matter, phytate and an organic solvent, and drying to obtain a precursor; and carrying out heating treatment on the precursor to obtain the nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material for the lithium-sulfur battery diaphragm. The preparation method of the lithium battery diaphragm comprises the following steps: mixing raw materials including the nitrogen-phosphorus doped carbon composite iron phosphide three-dimensional rod-like porous material, a binder and a solvent and dispersing to obtain coating slurry; and coating the surface of a diaphragm base material with the coating slurry to obtain the lithium battery diaphragm. According to the nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material, the lithium battery diaphragm, the preparation method of the lithium battery diaphragm and thelithium-sulfur battery, the shuttle effect can be effectively solved, and the electrochemical performance of the lithium-sulfur battery is improved.

Owner:湖南桑瑞新材料有限公司

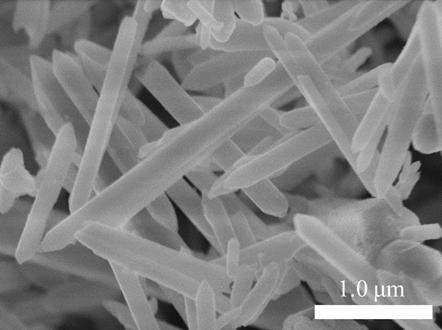

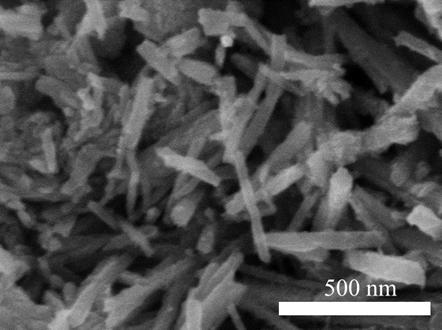

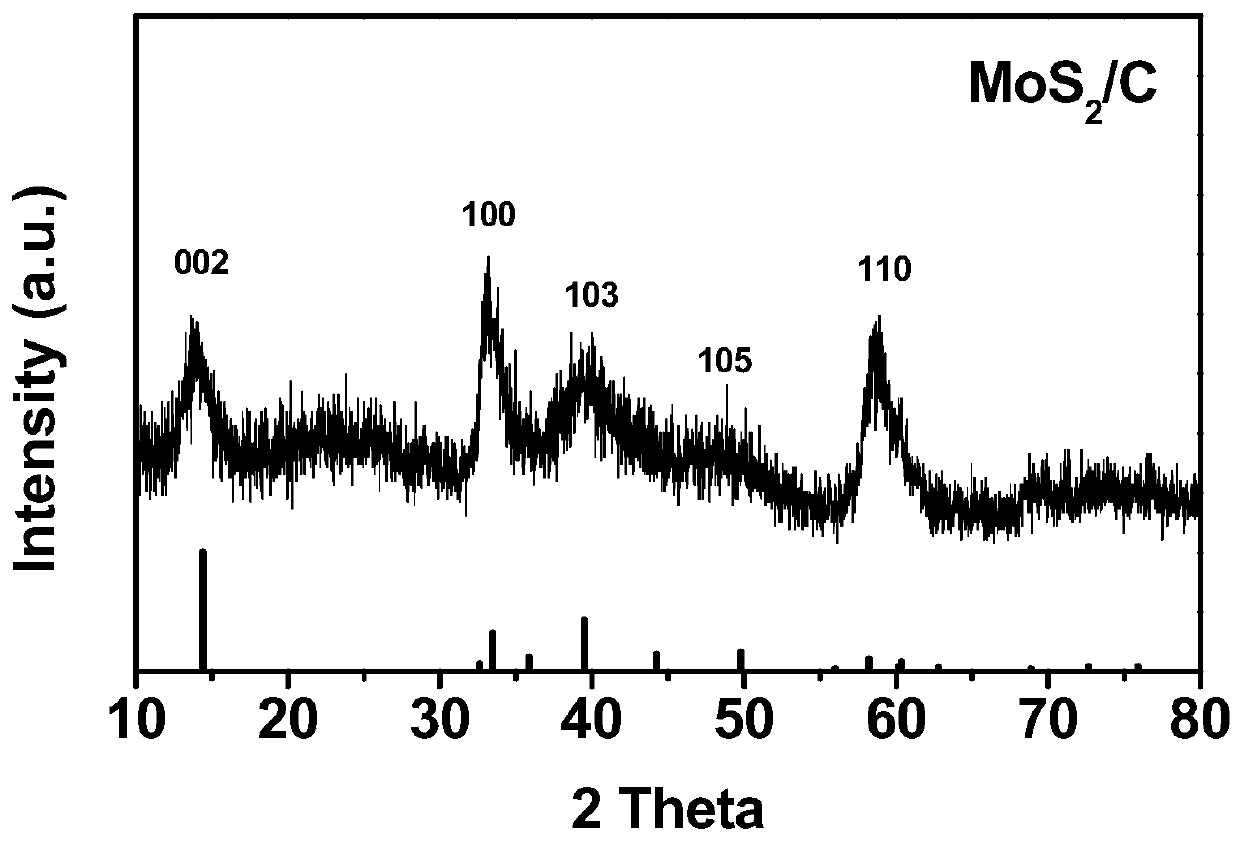

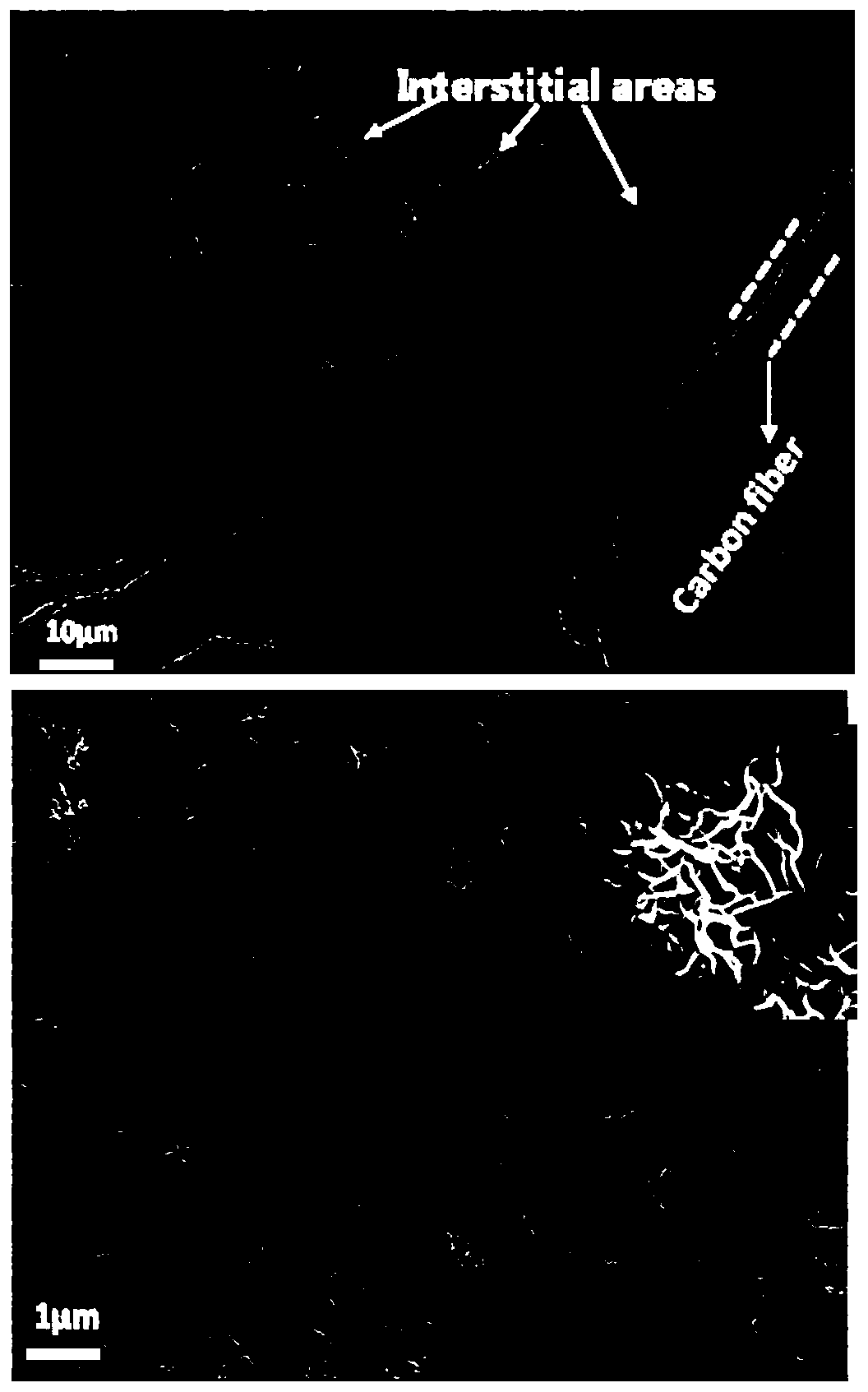

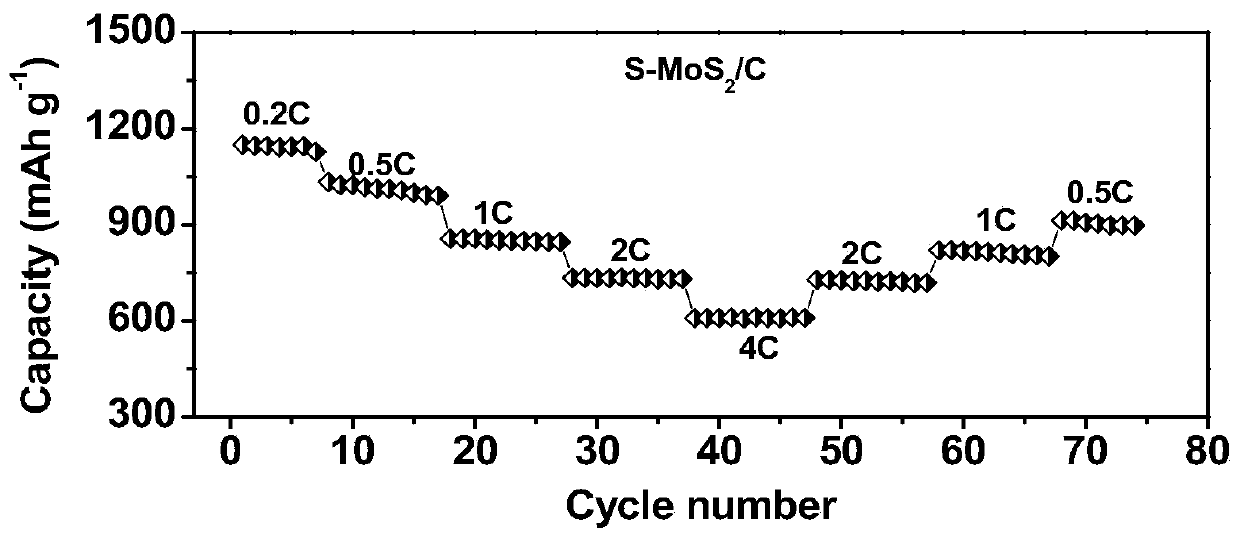

Preparation method for tissue-derived carbon fiber loaded MoS2 microflower composite material and application in lithium-sulfur battery

InactiveCN110783542AGentle methodImprove adsorption capacityPositive electrodesLi-accumulatorsFiberCarbon fibers

The invention belongs to the technical field of new energy materials, and particularly relates to a preparation method for a tissue-derived carbon fiber loaded MoS2 microflower composite material andthe application in a lithium-sulfur battery material. The method comprises the following steps of: soaking a commercial tissue in hydrochloric acid for 24 hours and conducting washing with water and drying, dissolving ammonium molybdate tetrahydrate and thiourea in water to obtain a mixed solution, immersing the treated tissue into the mixed solution, carrying out hydrothermal treatment, washing with water, and drying to obtain a sample, and calcining the sample in an inert atmosphere to obtain the tissue-derived carbon fiber loaded MoS2 microflower composite material. The method of preparingthe commercial tissue derived carbon fiber loaded MoS2 microflower composite material is mild, raw materials are easy to obtain, the cost is low, many effective anchoring sites are achieved, and adsorption and catalytic conversion of LiPSs are facilitated. And the content of active substances is as high as 72%.

Owner:UNIV OF JINAN

Catalyst based on volatile organic pollutant purification and preparation method thereof

InactiveCN109985661AEfficient emissionsMeet emission regulationsGas treatmentMolecular sieve catalystsMolecular sieveGas phase

The invention relates to a catalyst based on volatile organic pollutant purification and a preparation method thereof. A catalyst carrier is coated with an oxidizing catalyst coating, and the oxidizing catalyst coating contains a ZSM-5 molecular sieve, an Mn-Co-Zr composite oxide, ZrO2 sol and noble metal Au. The preparation method comprises an Mn-Co-Zr composite oxide synthesis step, a catalyst slurry preparation step and a catalyst slurry coating step. The catalyst can effectively catalyze oxidation of discharged pollutants, and can oxidize gas-phase pollutants, organic pollutants, CO and the like into harmless gas CO2 and H2O, so that requirements of emission regulations are met. The preparation method disclosed by the invention is simple, and the steps are easy to operate. The catalystprepared by the preparation method disclosed by the invention has good low-temperature ignition activity on organic pollutants and has a low CO ignition temperature, so that the reaction of the organic pollutants is promoted, and good durability is achieved.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

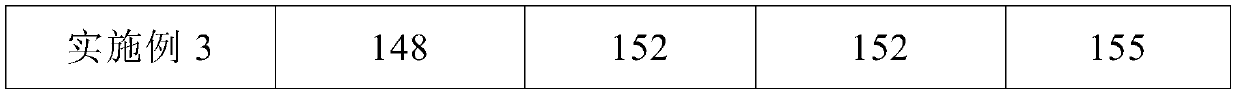

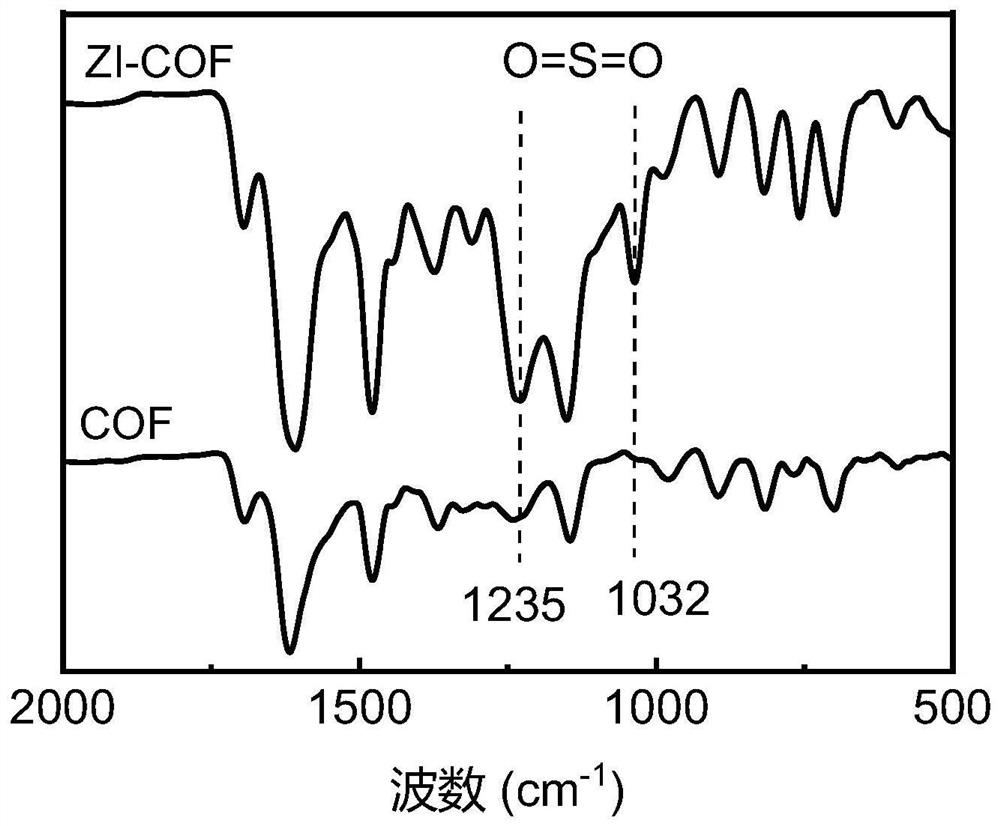

Covalent organic framework material rich in zwitterions as well as preparation method and application of covalent organic framework material

PendingCN114349921AInhibition of the shuttle effectFacilitate catalytic conversionElectrode thermal treatmentElectrode collector coatingLithium sulfurPhenyl group

The invention relates to a zwitter-ion-rich covalent organic framework material as well as a preparation method and application thereof. The covalent organic framework material is prepared by taking 3, 8-diamino-6-phenyl phenanthridine and benzenetricarboxaldehyde as raw materials and introducing sulfo groups through a post-modification method. According to the invention, sulfo groups are introduced to a COF skeleton, so that the COF skeleton has positive and negative charges; wherein positively charged nitrogen atoms and negatively charged sulfo groups not only can inhibit the loss of an active substance sulfur in the lithium-sulfur battery, but also can promote the catalytic conversion of polysulfide, so that the cycle performance of the lithium-sulfur battery can be remarkably improved.

Owner:HEBEI UNIV OF TECH

Bimetal phosphide inlaid carbon hollow nanocage as well as preparation method and application thereof

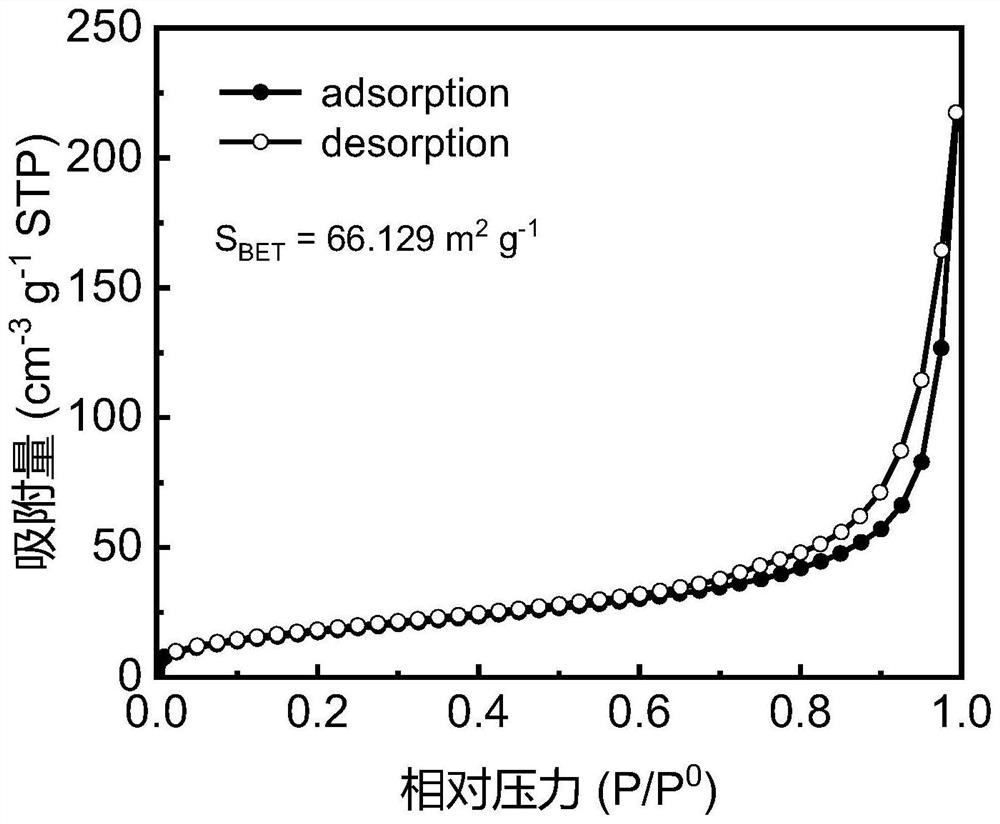

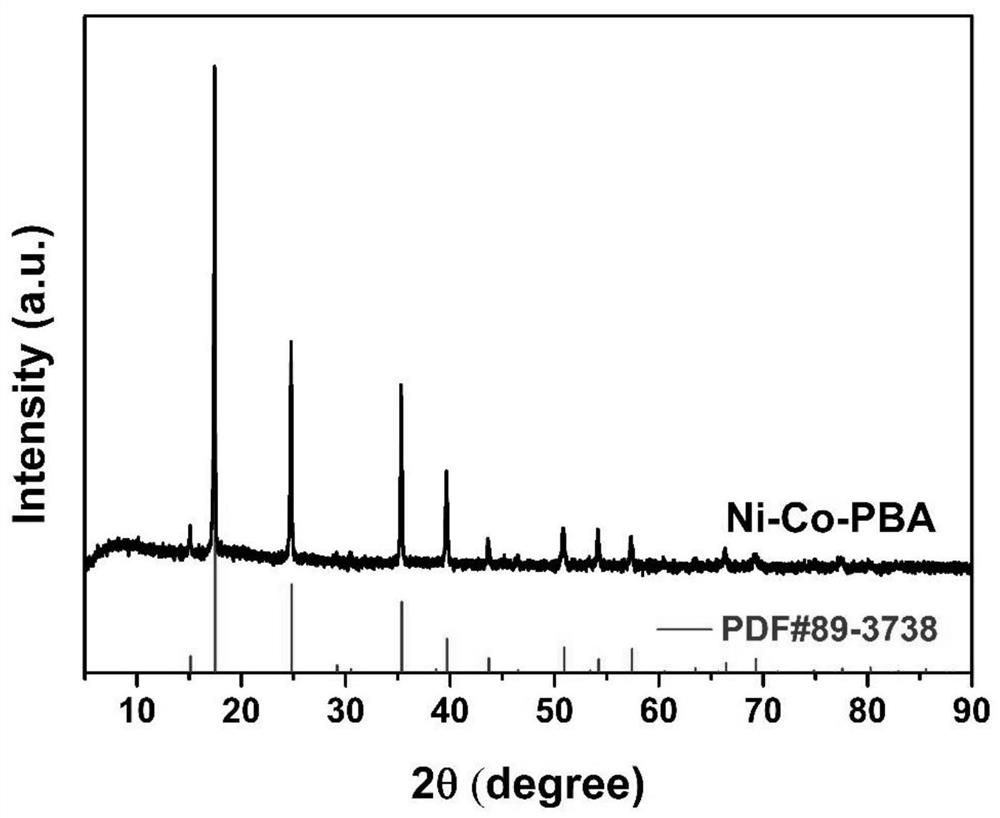

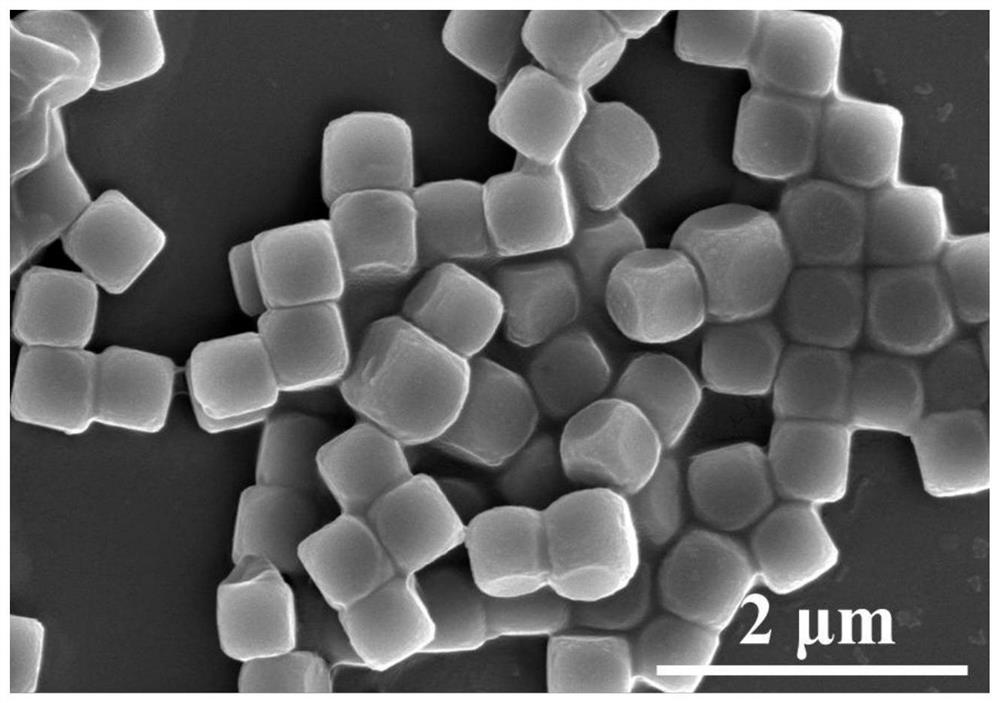

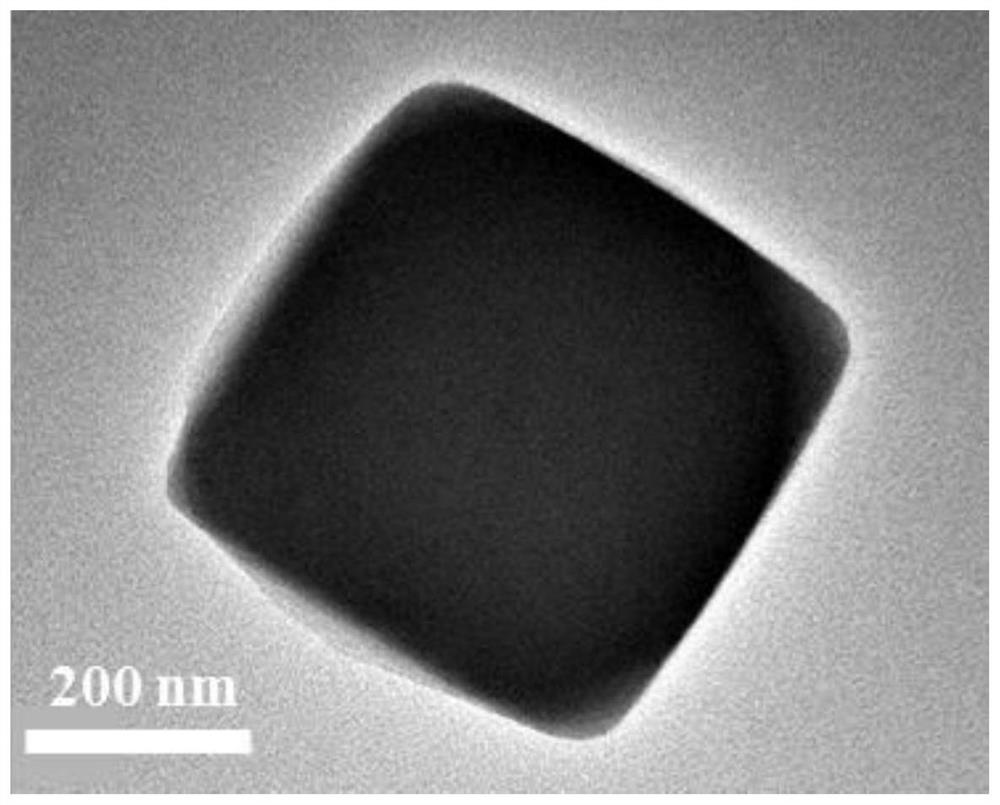

ActiveCN113066964ARegular structureAvoid short circuitMaterial nanotechnologyCell electrodesLithium–sulfur batteryLithium sulfur

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a bimetallic phosphide embedded carbon hollow nanocage and a preparation method and application thereof. The preparation method comprises the following steps: dispersing a nickel-cobalt Prussian blue derivative in a liquid medium, preparing dispersion liquid, adding dopamine hydrochloride into the dispersion liquid, and preparing nickel-cobalt prussian blue wrapped by the polydopamine; calcining the nickel-cobalt Prussian blue derivative wrapped by the polydopamine to prepare a nickel-cobalt bimetallic particle embedded carbon hollow nanocage; taking hydrogen phosphide as a phosphating agent, and carrying out one-step phosphating on the carbon hollow nanocage inlaid with the bimetallic particles to prepare the carbon hollow nanocage inlaid with the bimetallic phosphide; preparing a dispersion liquid from a bimetallic phosphide embedded carbon hollow nanocage, carbon black and polyvinylidene fluoride, then coating a polypropylene diaphragm with the dispersion liquid, and performing drying to prepare a multifunctional diaphragm. The comprehensive performance of the lithium-sulfur battery is remarkably improved.

Owner:NANCHANG UNIV

Preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oils and oxygenated chemical

ActiveCN102206502BFacilitate catalytic conversionReduce energy consumptionHydrocarbon purification/separationLiquid hydrocarbon mixture productionOil and greaseReaction temperature

A preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oil and an oxygenated chemical is characterized by: introducing raw materials such as the plant oil and the oxygenated chemical into a catalytic cracking reactor; carrying out a catalytic conversion reaction through contacting with a catalytic cracking catalyst in the reactor with an operating temperature of 500 to 670 DEG C, an operating pressure of 0.1 to 5.0 MPa, a weight hourly space velocity of 0.1 to 100 h<-1> and an agent-oil ratio of 1 to 50; separating a reaction oil gas from the spent catalyst when the reaction is finished; recycling the separated spent catalyst after stripping, burning and regenerating; obtaining fractions such as a liquefied gas, gasoline and the like through fractionating the reaction oil gas and obtaining the low-carbon olefins through a manner that the liquefied gas enters a gas separating system; and obtaining the aromatic hydrocarbon product through carrying out a further aromatic extraction on the gasoline fraction. The method provided by the present invention allows the reaction temperature to be controlled through co-processing the plant oil and the oxygenated chemical, the selectivity of the target product gasoline to be improved, and energy consumption to be reduced. In terms of a reaction apparatus, equipment flow is simplified because heat exchangers which are arranged for removing reaction heat can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Porous intermetallic compound-ceramic catalyst carrier and preparation thereof

InactiveCN101301630BFacilitate catalytic conversionFully contactedCatalyst carriersDispersed particle separationSelf-propagating high-temperature synthesisPorous catalyst

Owner:SHANDONG UNIV OF SCI & TECH

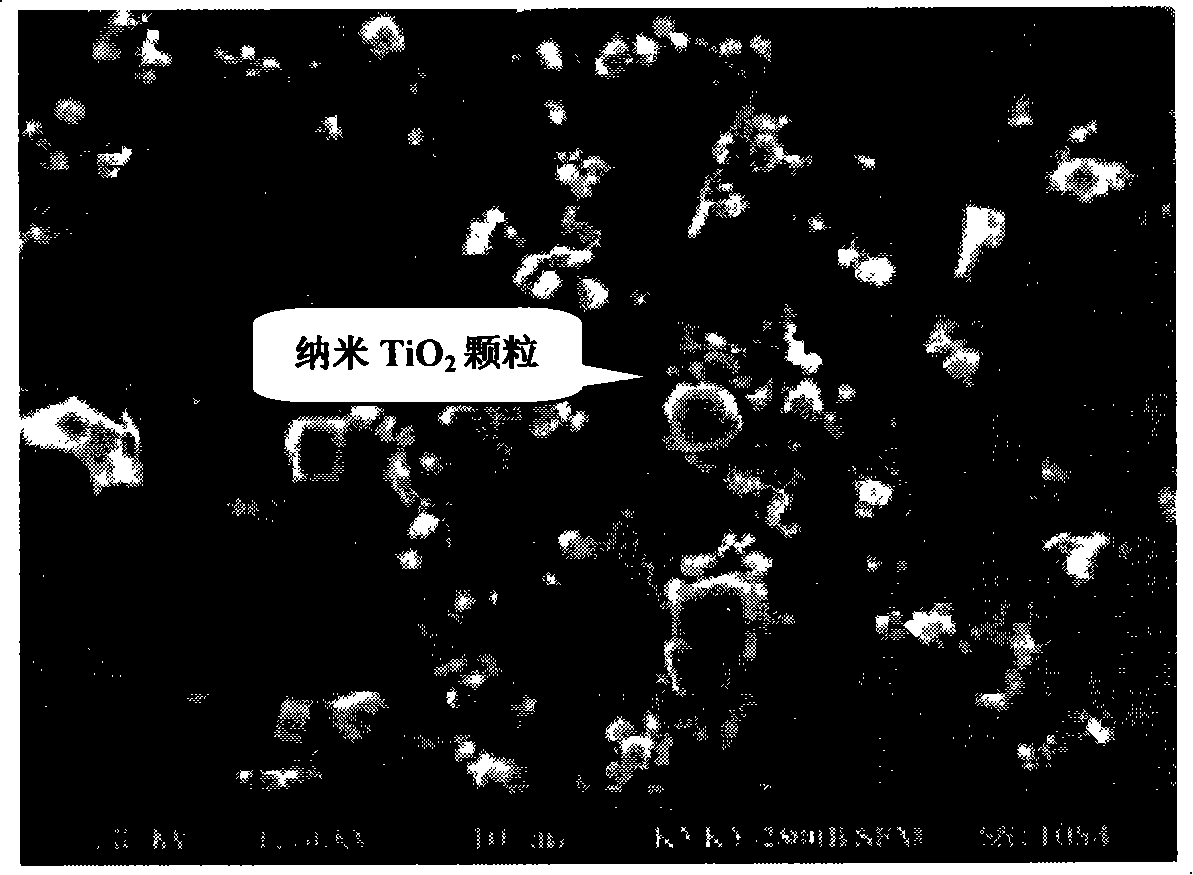

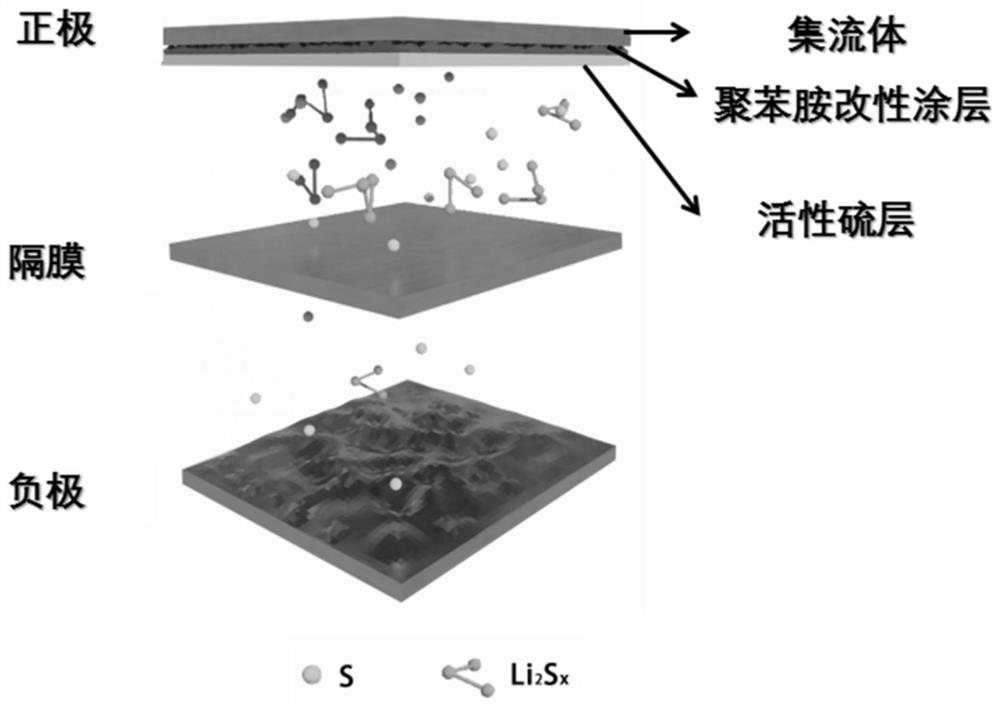

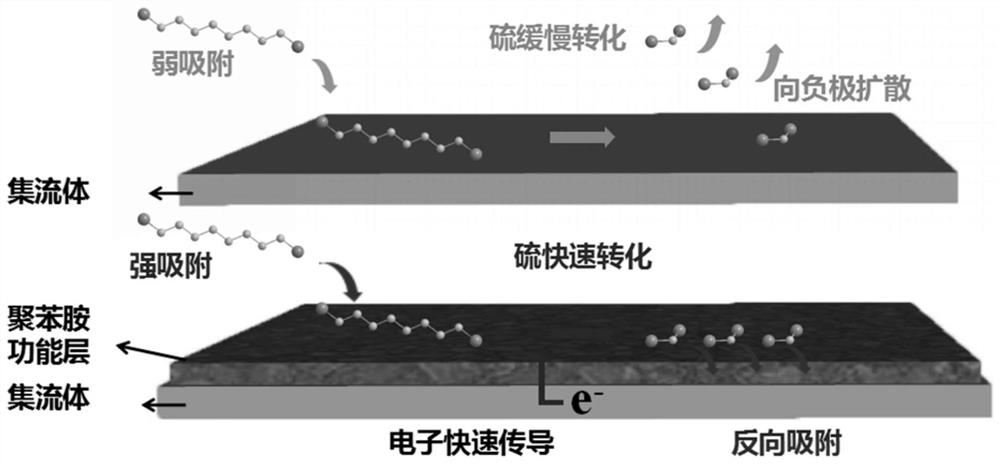

Preparation method of conjugated microporous polyaniline modified battery current collector and application of conjugated microporous polyaniline modified battery current collector in lithium-sulfur battery

PendingCN114335558AImprove conductivityEnhanced chemical adsorption capacityElectrode carriers/collectorsLi-accumulatorsPtru catalystLithium–sulfur battery

The invention relates to a preparation method of a conjugated microporous polyaniline modified battery current collector and an application of the conjugated microporous polyaniline modified battery current collector in a lithium-sulfur battery, and the preparation method comprises the following steps: adding tris (4-bromoaniline) and a linker into a solvent in a nitrogen atmosphere, and uniformly stirring to prepare a to-be-reacted solution; adding an oxidizing agent, a catalyst and NaF into the solution to be reacted, and reacting to obtain conjugated microporous polyaniline powder; the preparation method comprises the following steps: mixing conjugated microporous polyaniline powder with a binder, and carrying out ball milling to form current collector modified slurry; and brushing the current collector modified slurry onto the surface of a battery current collector, and drying to obtain the conjugated microporous polyaniline modified current collector. According to the invention, the functions of adsorbing polysulfide, inhibiting a shuttle effect and buffering and protecting the structure of the current collector are realized, and efficient transmission of electrons from an external circuit can also be ensured; when the current collector with the polyaniline modified coating is applied to a lithium-sulfur battery, the current collector with the polyaniline modified coating can effectively improve the cycling stability of the battery and shows a long service life of the battery.

Owner:XI AN JIAOTONG UNIV

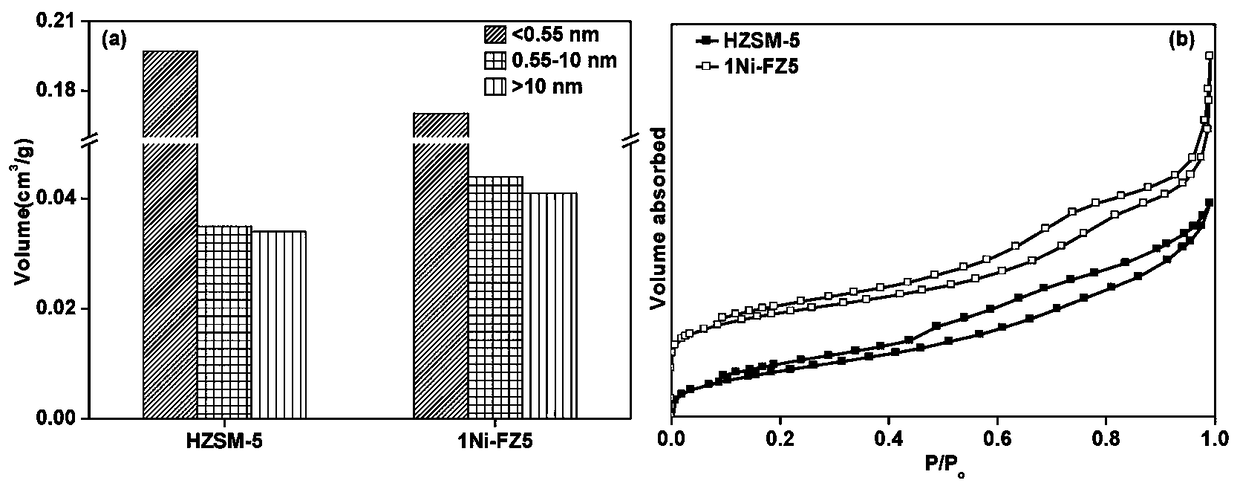

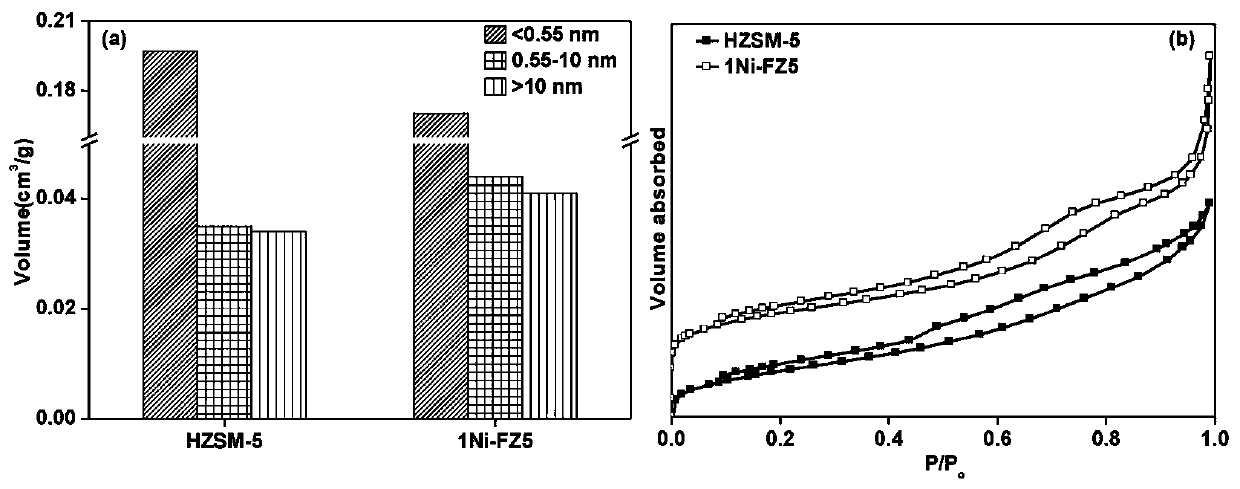

Preparation method and application of Ni-doped hierarchical porous ZSM-5 molecular sieve

ActiveCN109078652AFacilitate catalytic conversionHigh yieldMolecular sieve catalystsCatalyst activation/preparationCatalytic reformingHigh activity

The invention discloses a preparation method and application of Ni-doped hierarchical porous ZSM-5 molecular sieve. The preparation method includes the steps of pretreating a molecular sieve, namely roasting to remove a templating agent and water; etching the molecular sieve with HF (hydrofluoric) acid solution to generate a hierarchical porous structure; loading high-activity metallic nickel by impregnation; carrying out sheeting and screening. Application of the molecular sieve herein in catalytic quick pyrolysis of biomass is also disclosed. The zeolite HZSM-5 that is low in price and easyto obtain is used herein as a matrix; desilication and dealumination treatment is performed while fiver-membered and ten-membered ring intersection micro porosity of the matrix is utilized, so that hierarchical pores good for entering of macromolecules are generated. The preparation method herein allows acid site distribution to be reduced at the premise of pore expansion; on such basis, the low-price metallic nickel with high hydrogen transfer capacity is added, so that high passing rate and high conversion rate of macromolecules during catalysis are achieved. A catalyst prepared via the preparation method has the advantages of low price, good access convenience, and simple process, is mainly applicable to the catalytic pyrolytic test of biomass or coal, and has a good prospect of catalytic reforming of pyrolytic volatiles.

Owner:CHINA UNIV OF MINING & TECH

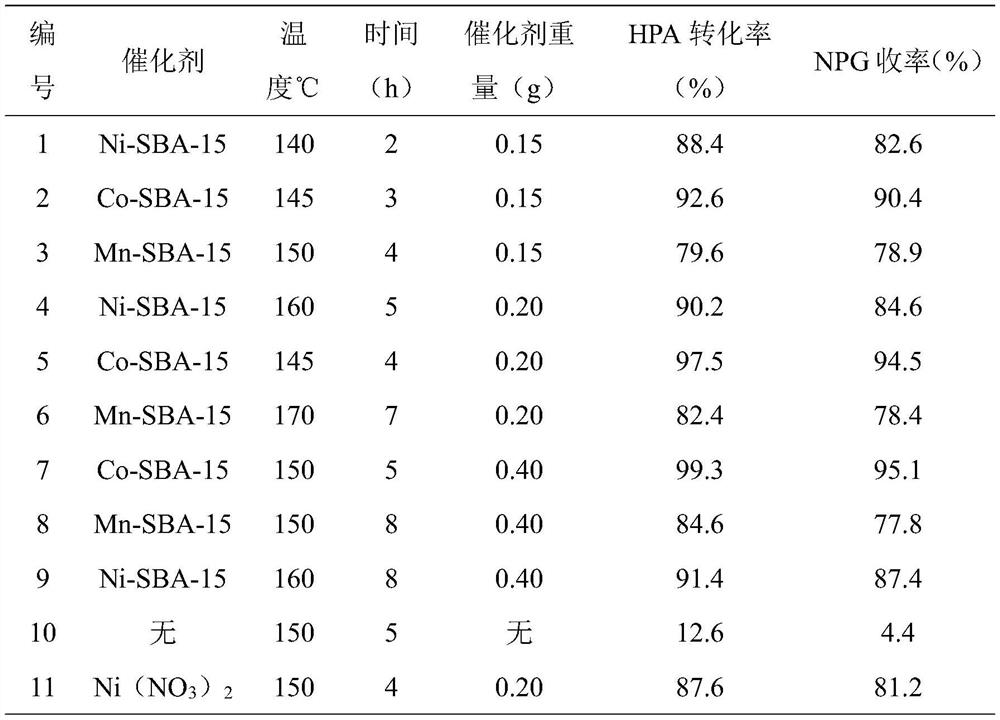

Method for synthesizing neopentyl glycol through catalytic hydrogenation of hydroxyvaleraldehyde

PendingCN113121308AImprove thermal stabilityGood choiceMolecular sieve catalystsOrganic compound preparationPtru catalystCombinatorial chemistry

The invention discloses a method for synthesizing neopentyl glycol through catalytic hydrogenation of hydroxyvaleraldehyde, which comprises the following steps of by taking hydroxyvaleraldehyde HPA as a raw material, adding an M-SBA-15 catalyst, placing in a high-pressure reaction kettle, introducing 3Mpa hydrogen for reaction, and collecting a product neopentyl glycol NPG and a byproduct 1115 ester after the reaction is accepted. The transition metal (Co, Mn or Ni)-doped SBA-15 catalyst (M-SBA-15) is applied to the reaction of synthesizing neopentyl glycol through catalytic hydrogenation of hydroxyvaleraldehyde, and has excellent performance on selective catalytic generation of neopentyl glycol, experiments prove that the conversion rate of HPA reaches 99% or above, the yield of the product NPG is 95% and is obviously improved compared with that of a traditional method, therefore, the method has important significance and application prospect in the technical field.

Owner:YUNNANHENGGANGSCIENCE&TECH LTD

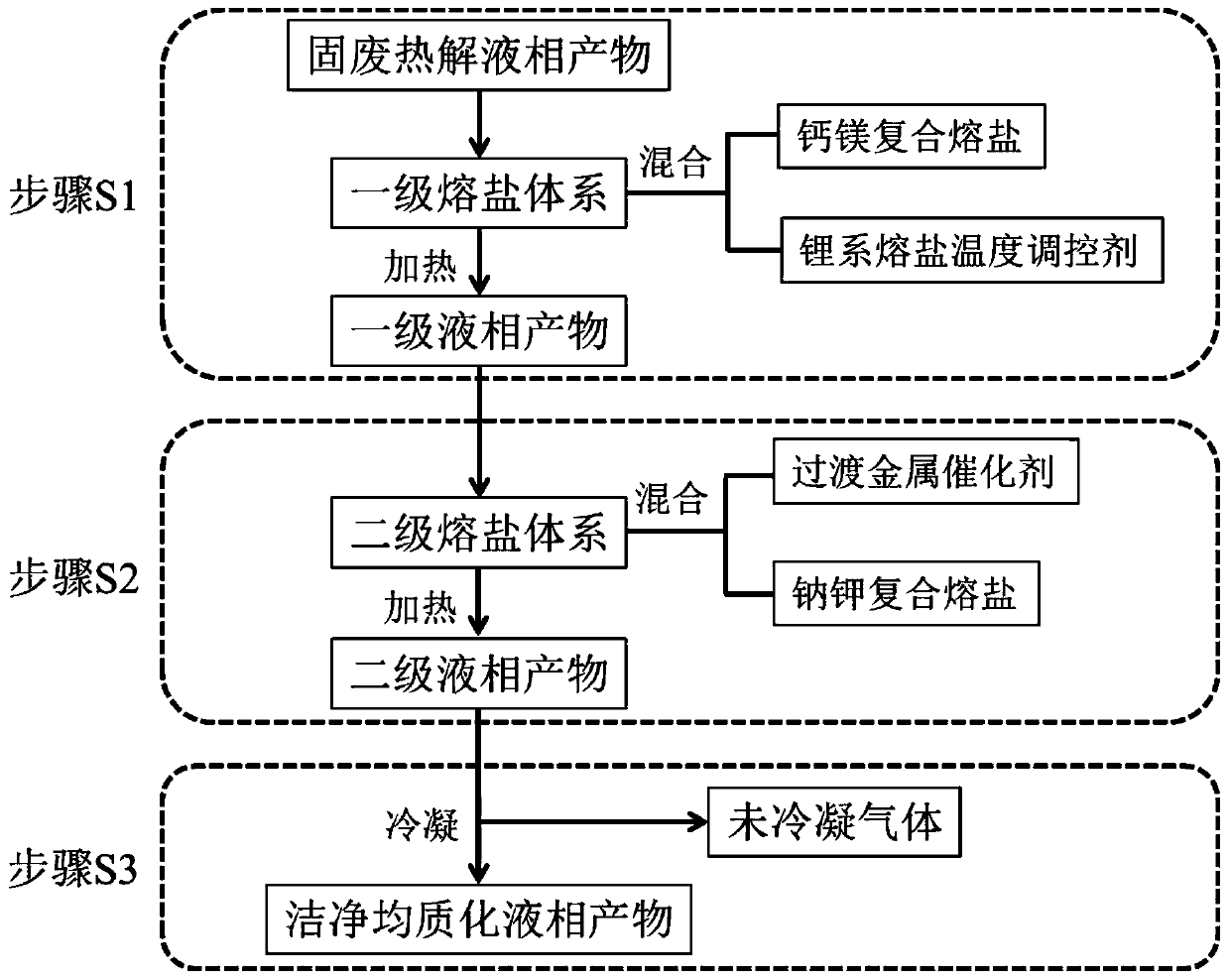

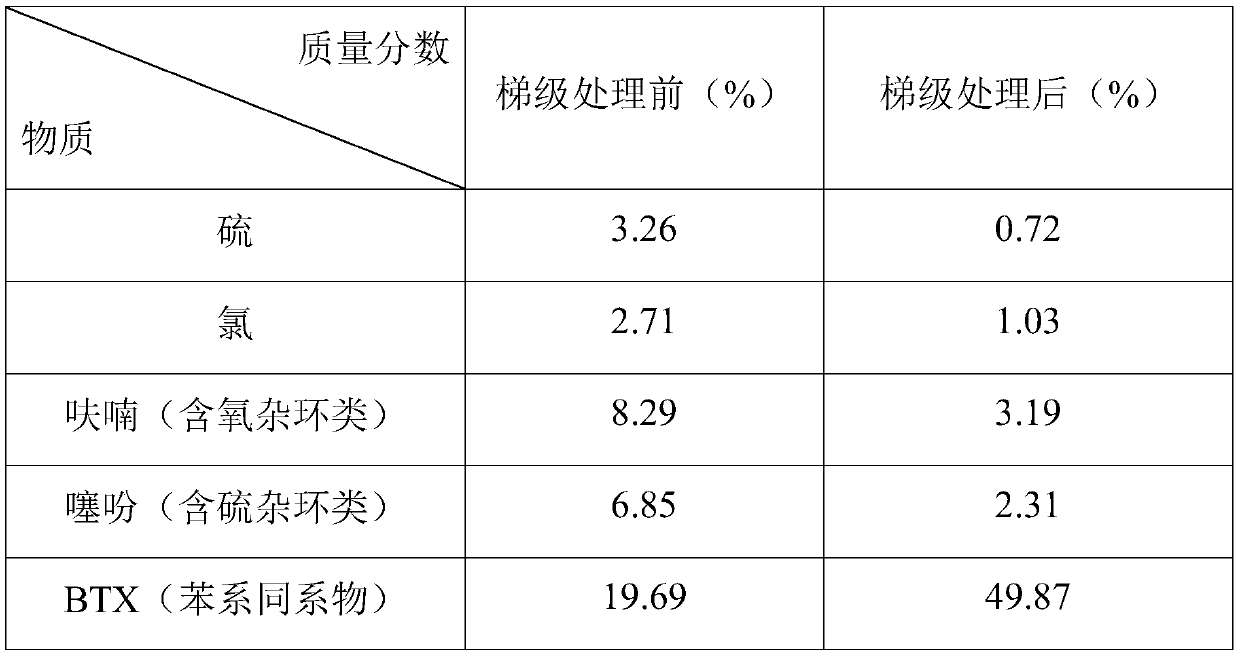

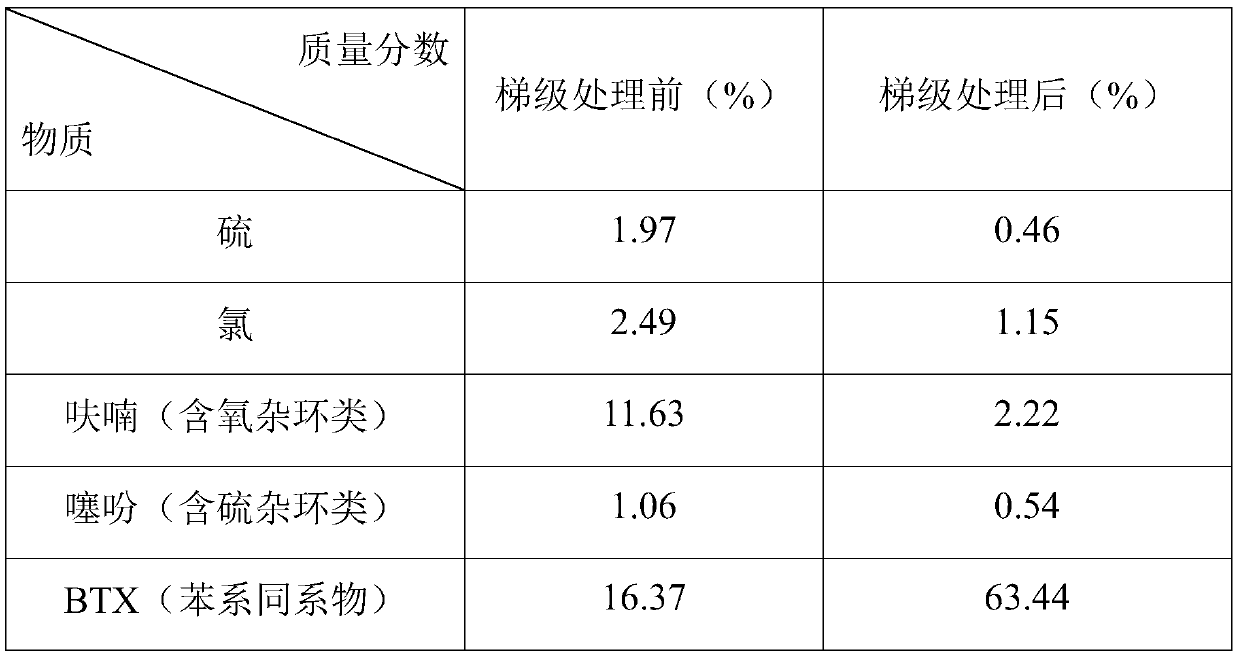

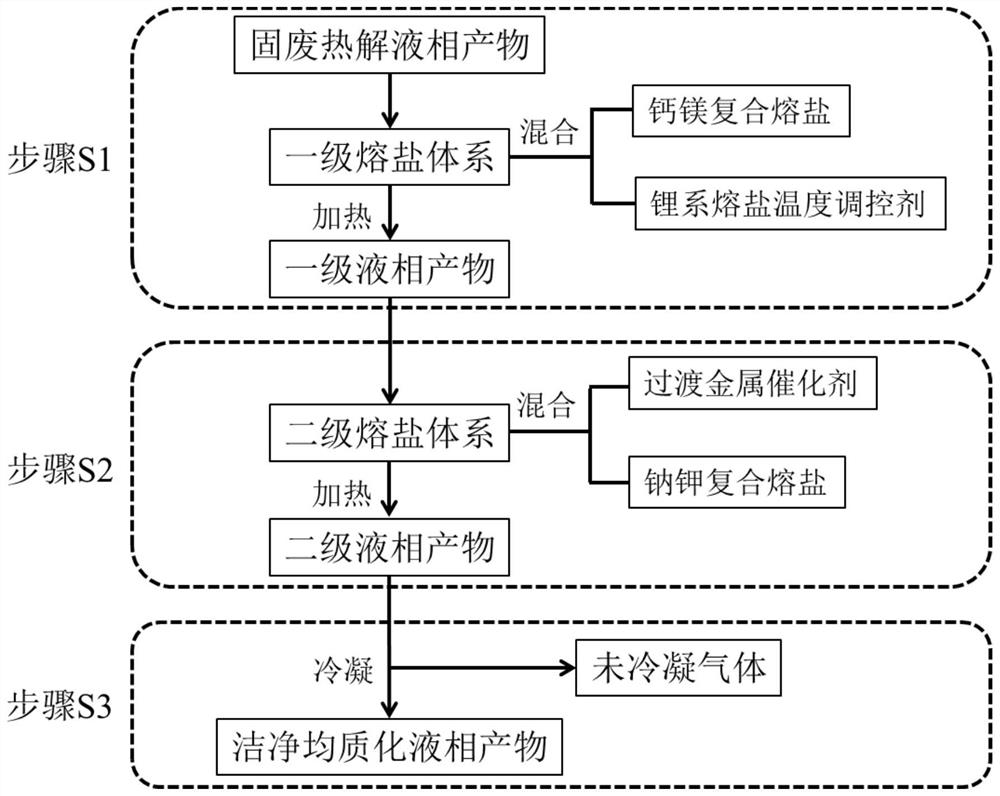

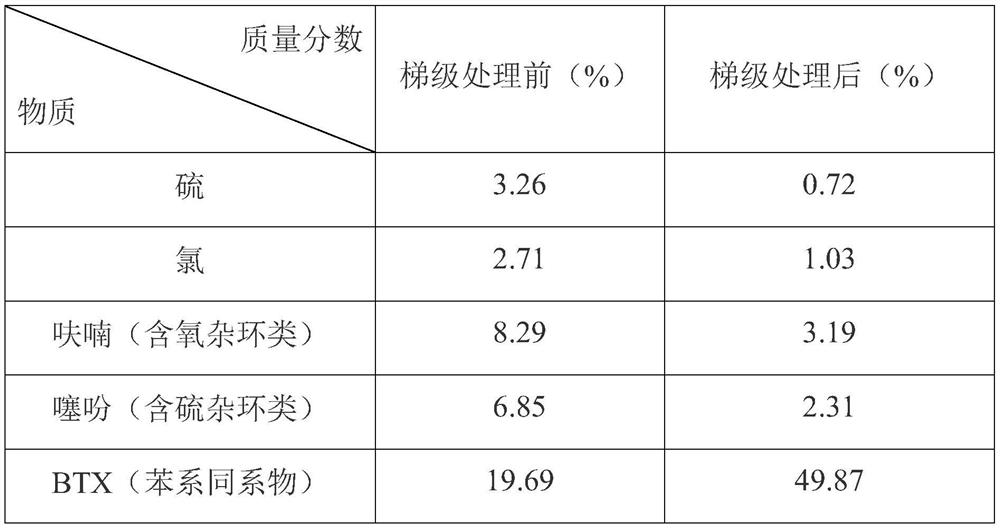

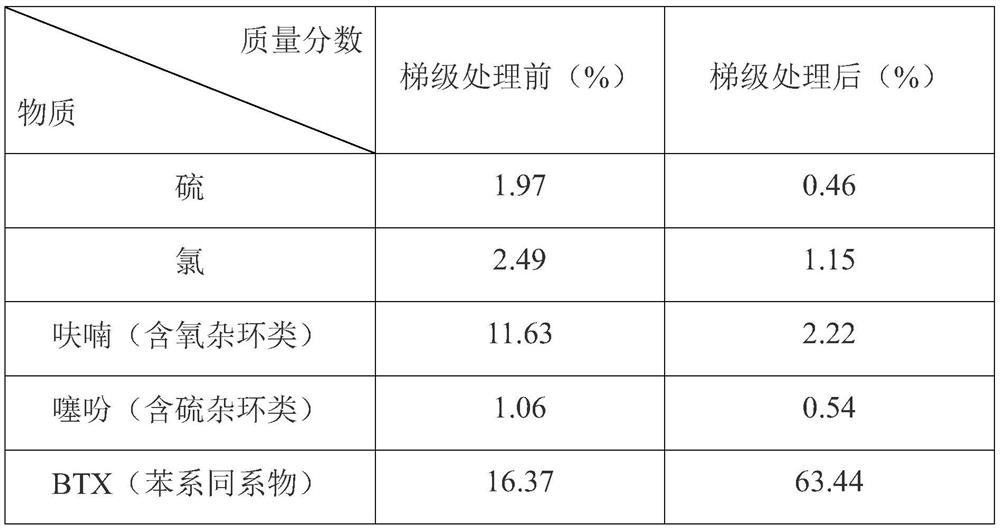

Solid waste pyrolysis liquid-phase product impurity removal and grading method and product

ActiveCN111440635AReduce generationEfficient disposalGaseous fuelsLiquid carbonaceous fuelsPtru catalystFluid phase

The invention belongs to the field of solid waste treatment, and particularly discloses a solid waste pyrolysis liquid-phase product impurity removal and grading method and a product. The method specifically comprises the following steps: mixing a lithium-based molten salt temperature regulating agent with calcium-magnesium composite molten salt to obtain a primary molten salt system, introducinga solid waste pyrolysis liquid-phase product into the primary molten salt system, heating, and keeping the temperature for a preset time, thereby realizing low-temperature impurity removal and obtaining a primary liquid-phase product; mixing a transition metal catalyst with sodium-potassium composite molten salt to obtain a secondary molten salt system, introducing the primary liquid-phase productinto the secondary molten salt system, heating, and keeping the temperature for a preset time, thereby realizing high-temperature upgrading and obtaining a secondary liquid-phase product; and carrying out condensation separation on the secondary liquid phase product, and respectively collecting uncondensed gas and a clean homogenized liquid phase product. According to the method, the solid wastepyrolysis liquid-phase product is subjected to grading treatment by adopting a molten salt cascade treatment method, so that the generation of pollutants is reduced, the production efficiency is improved, and meanwhile, the effective treatment of the solid waste pyrolysis liquid-phase product is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

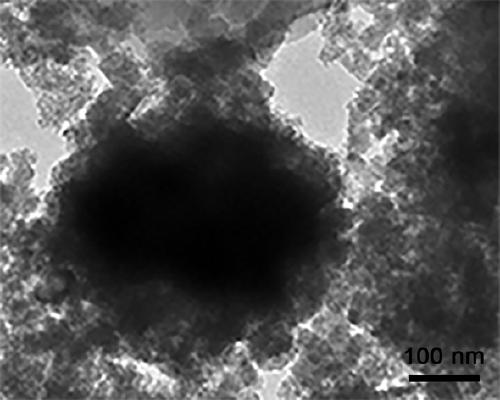

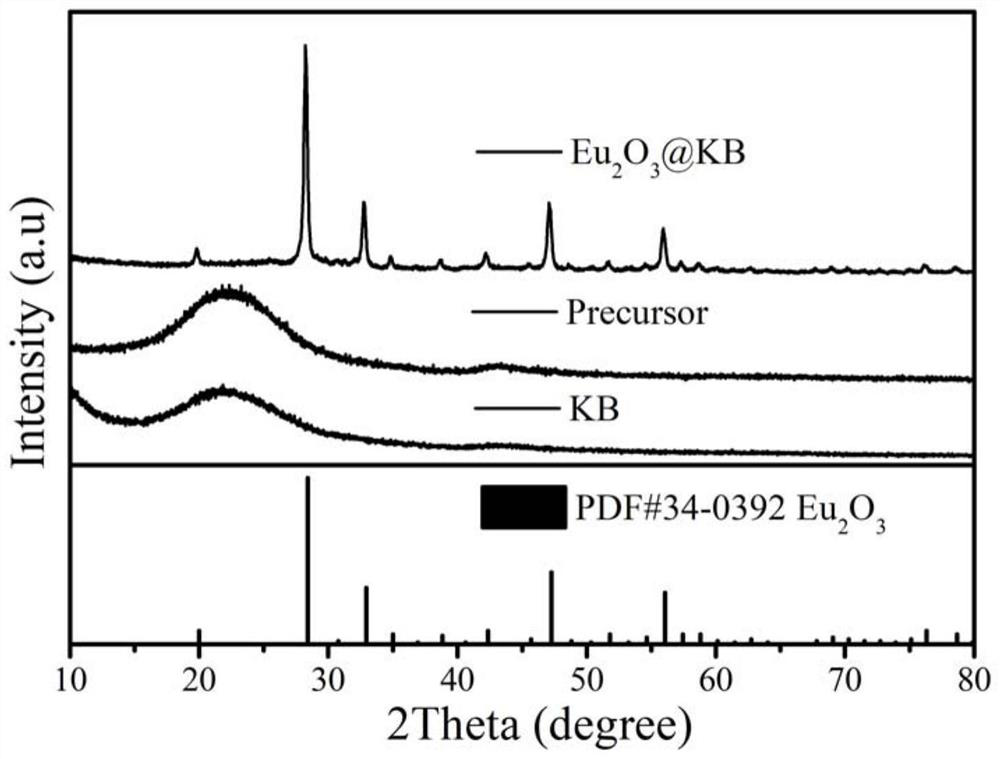

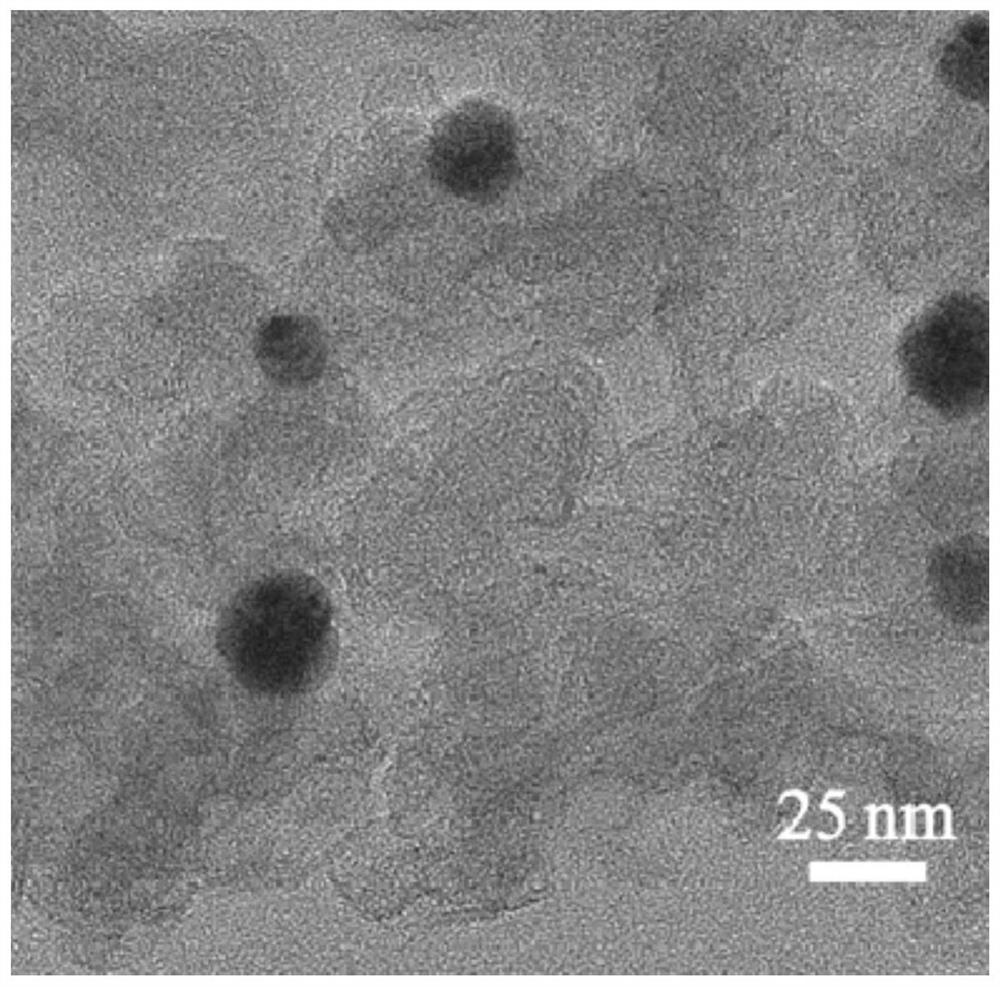

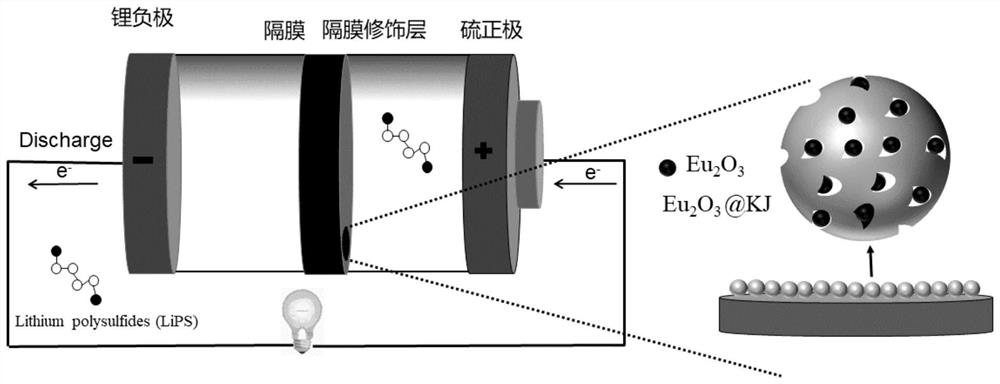

Porous carbon loaded europium oxide material as well as preparation method and application thereof

ActiveCN112688020AEasy to makeProspects for large-scale industrial productionLi-accumulatorsCell component detailsPorous carbonNew energy

The invention belongs to the field of new energy materials and devices, and discloses a porous carbon loaded europium oxide material as well as a preparation method and application thereof. Porous carbon and europium nitrate are mainly used as raw materials, a pH value control deposition method is adopted for preparation at room temperature, a carbon precursor can be obtained through ultrasonic treatment, stirring, suction filtration and drying, nitrogen is introduced into the precursor in a tubular furnace, calcination is performed at 700-1000 DEG C, and the porous carbon loaded europium oxide material can be obtained. The material can be used as a lithium-sulfur battery diaphragm modification material. Under the multiplying power of 0.05 C (1C = 1675mAh / g), the specific discharge capacity of the first circle can reach 1610mAh / g, and under the multiplying power of 1C, after 500 circles of circulation of a battery assembled by using the Ketjen black-loaded europium oxide material for the diaphragm modification layer, the capacity attenuation rate of each circle is only 0.05%, and compared with a blank diaphragm coated with Ketjen black and uncoated materials, the specific capacity is increased obviously and the excellent cyclic stability is realized.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for preparing catalytic cracking sulfur reduction additive

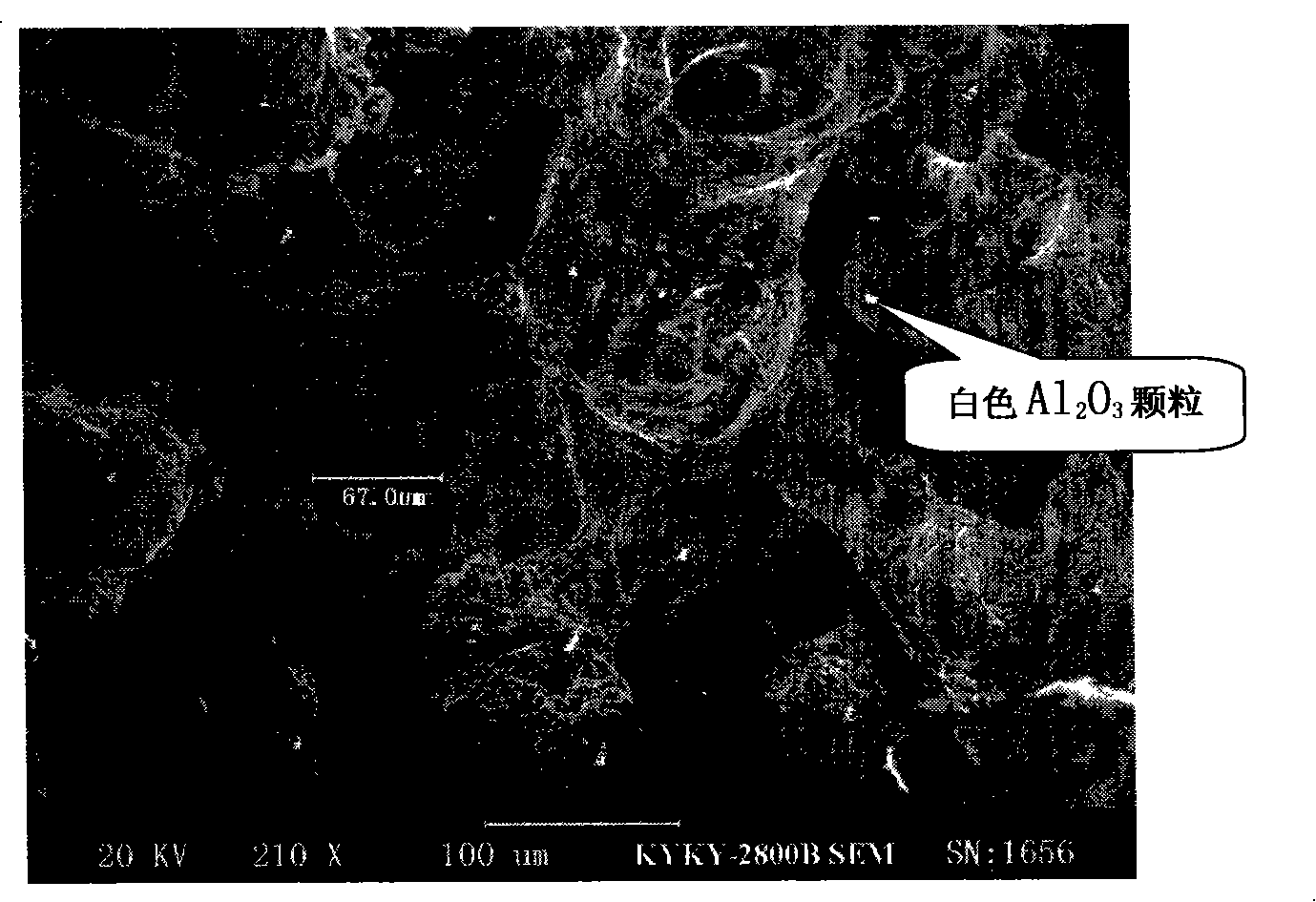

InactiveCN1208432CImprove adsorption capacityFacilitate catalytic conversionCatalytic crackingGasolineZinc

A method for preparing a catalytic cracking sulfur reduction additive, which is to use a catalytic cracking balancer with a vanadium content of 0.3%-1.2% and a micro-reaction activity greater than 45 directly as a catalytic cracking sulfur reduction additive, or through activation and / or loading The metal component zinc is used as a catalytic cracking sulfur reduction additive. The invention is easy to operate, practical and economical, not only creates favorable conditions for the recycling of waste agents, but also can significantly reduce the sulfur content of catalytic cracking gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

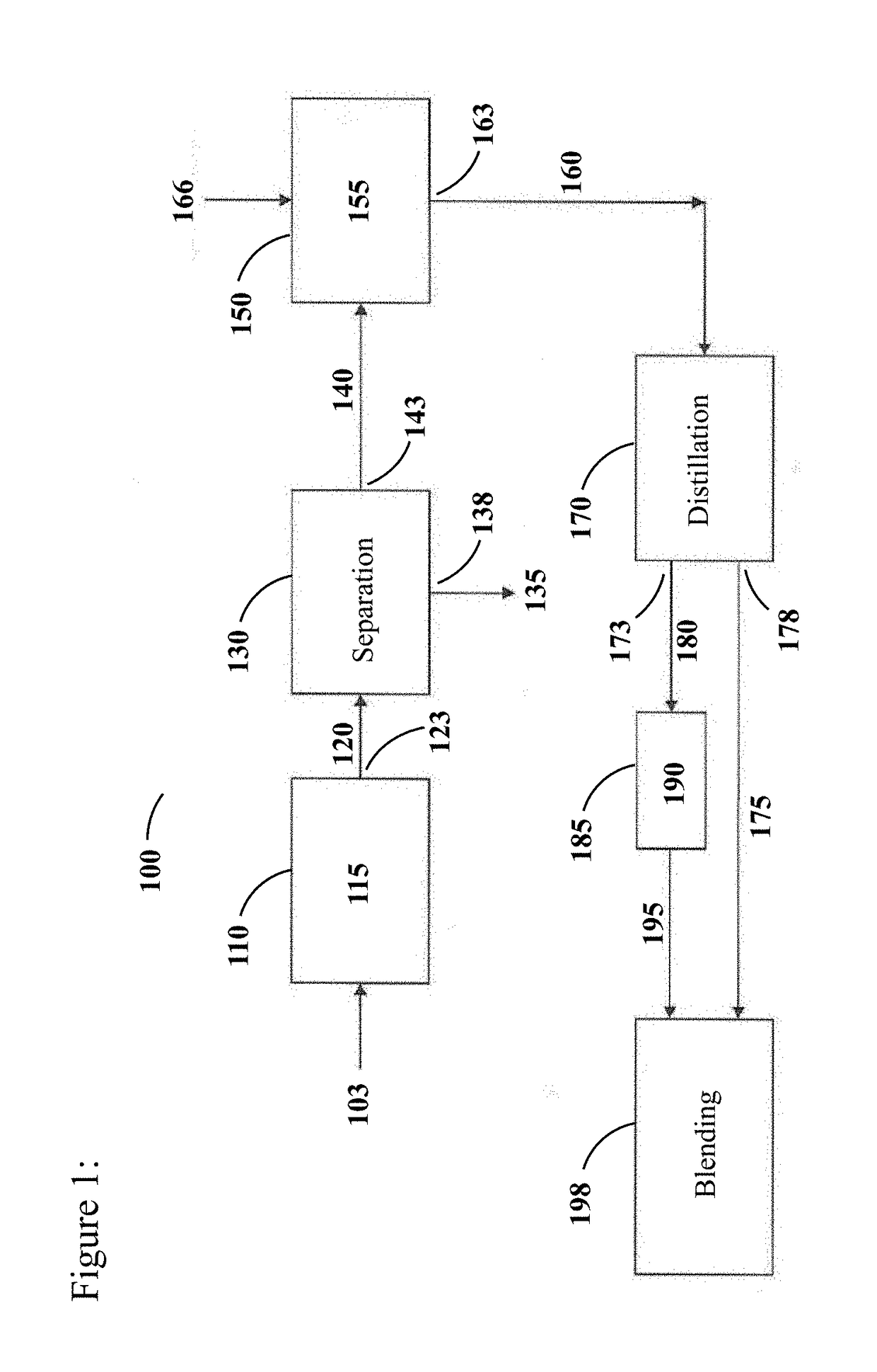

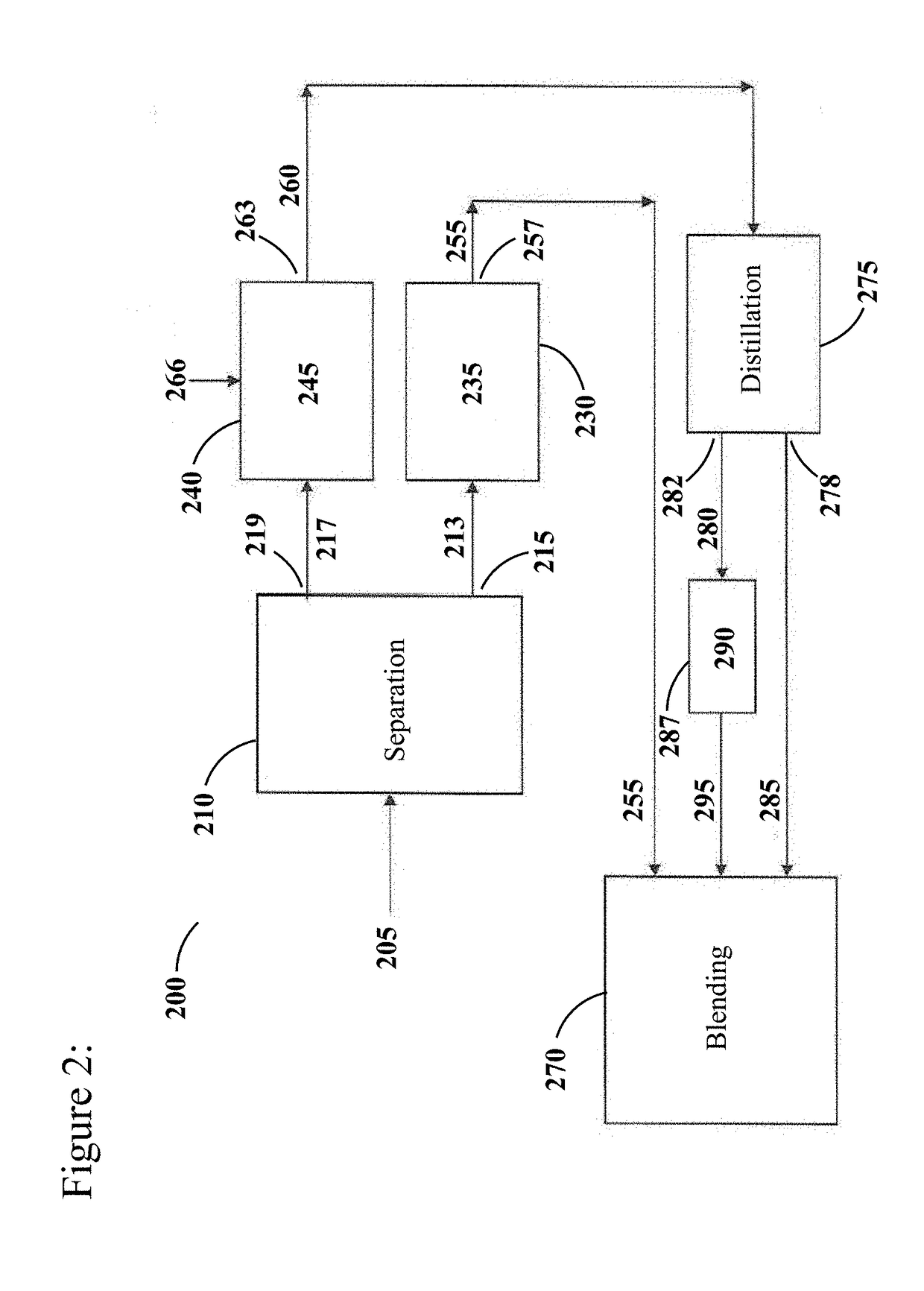

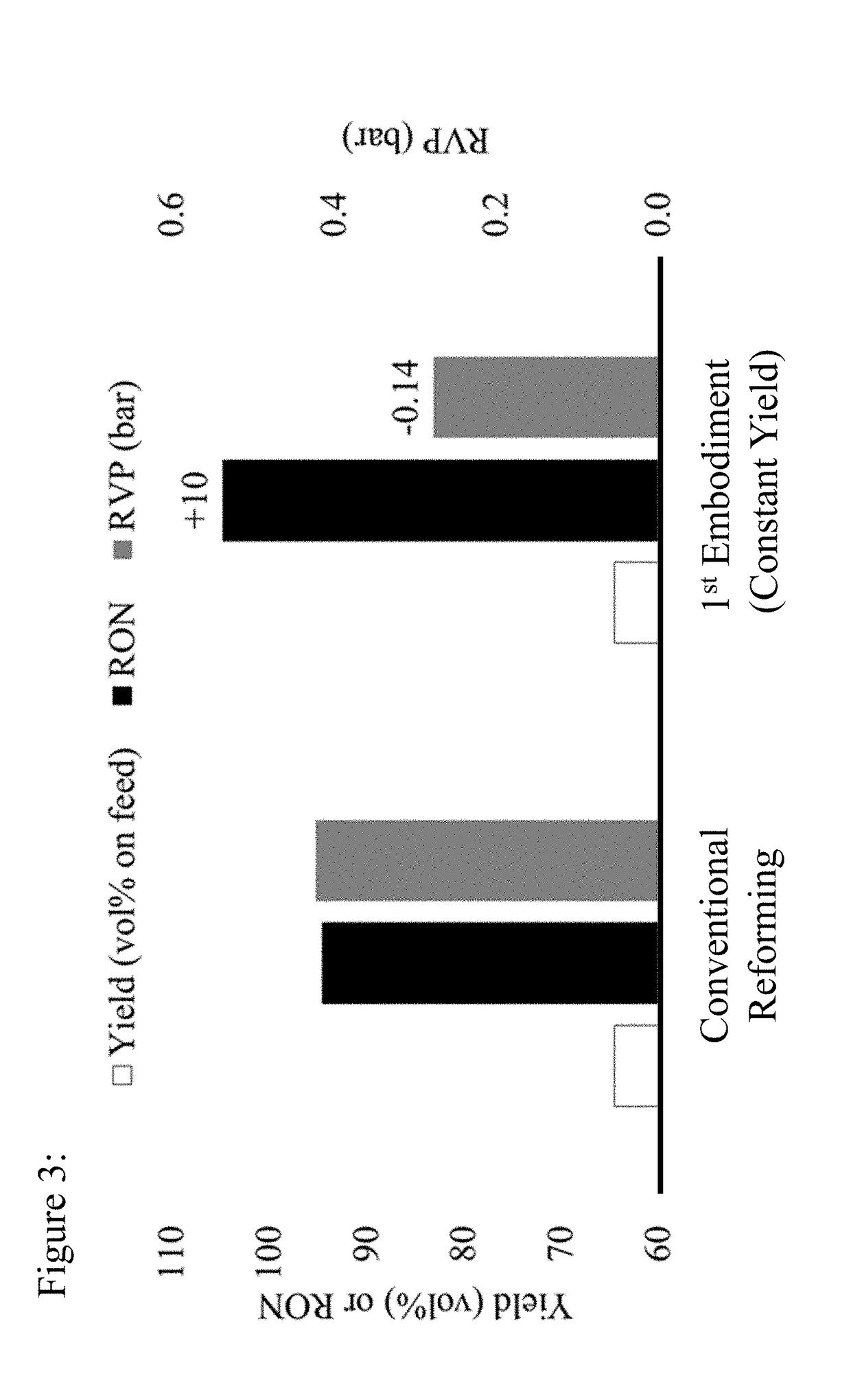

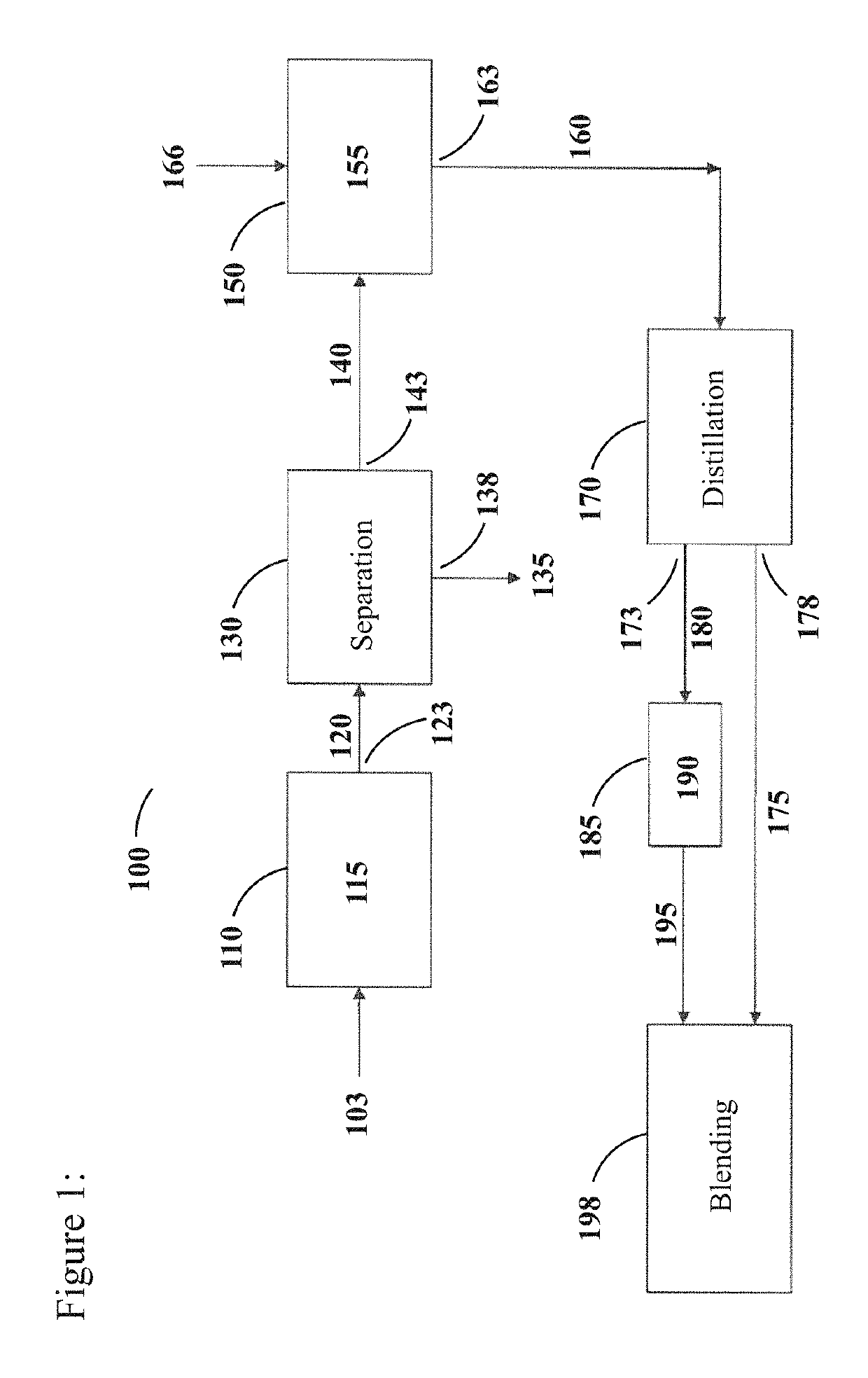

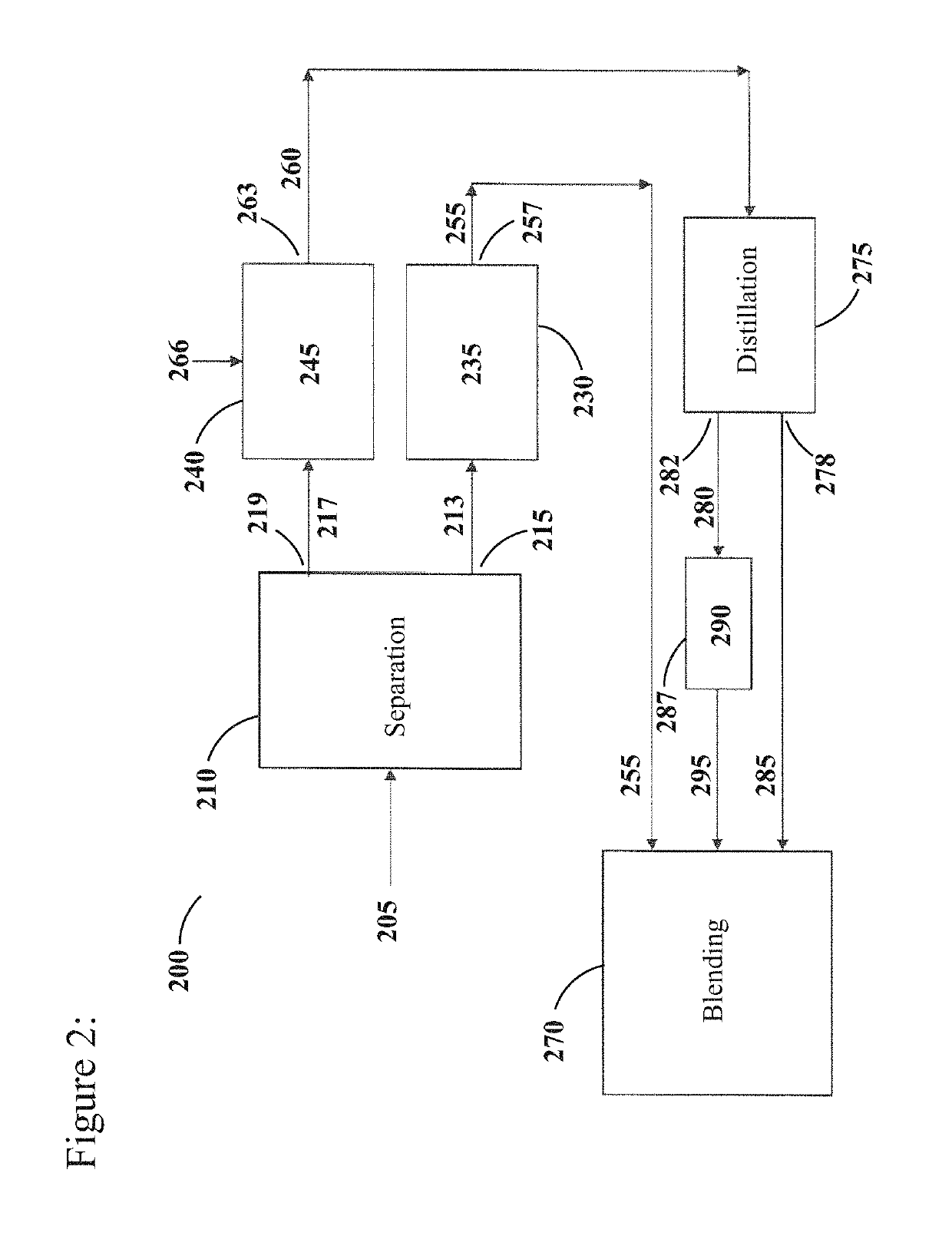

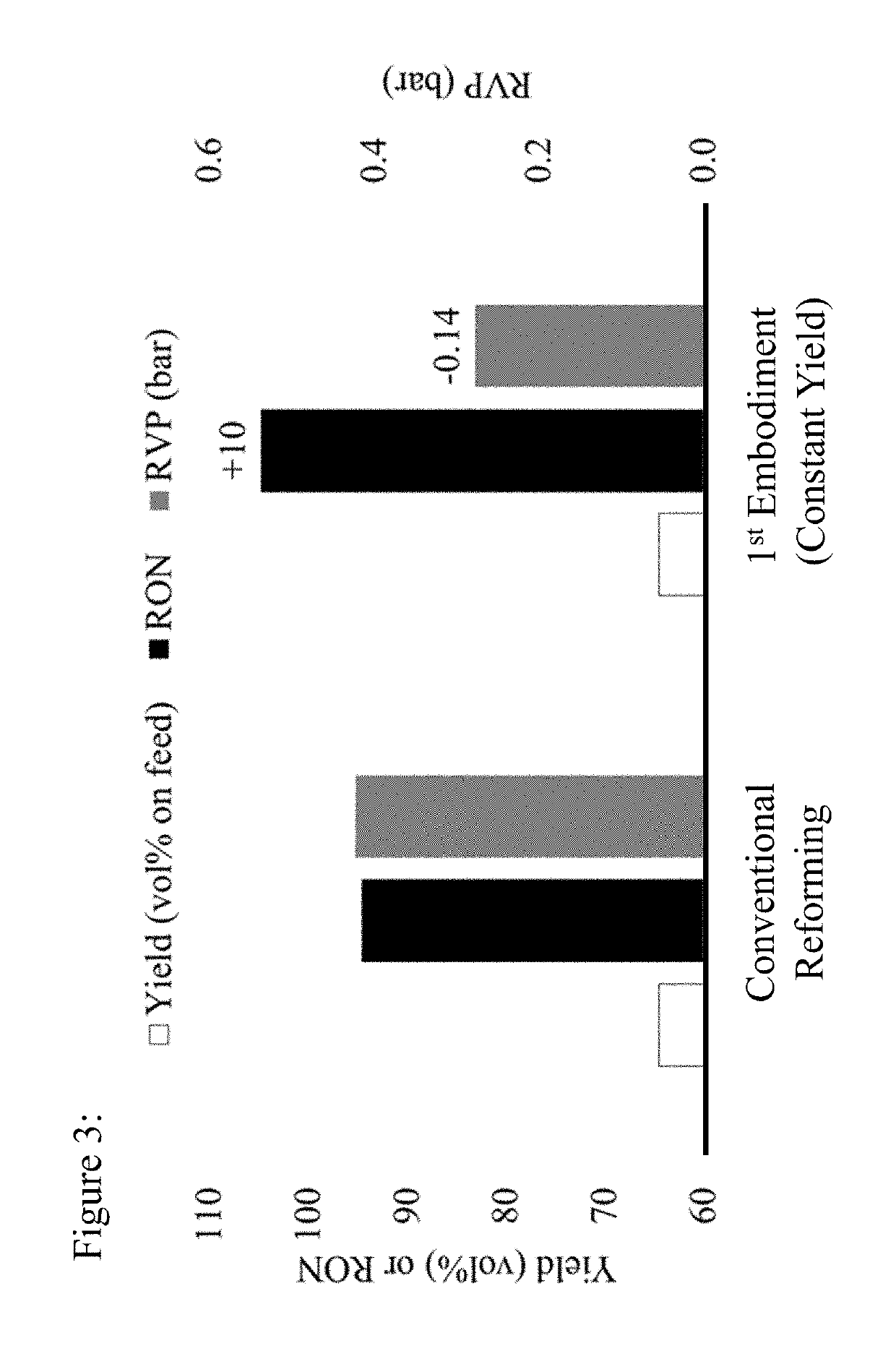

Selective naphtha reforming processes

ActiveUS20190062649A1Facilitates catalytic aromatizationIncreased research octane numberNaphtha treatmentHydrocarbon oils treatmentNaphthaLiquid hydrocarbons

Processes for reforming a hydrocarbon feedstock by selectively reforming different sub-components of the feedstock using at least two compositionally-distinct reforming catalysts. Advantages may include a decreased rate of reforming catalyst deactivation and an increased yield of a liquid hydrocarbon reformate product that is characterized by at least one of an increased octane rating and a decreased vapor pressure (relative to conventional one-step reforming processes and systems).

Owner:PHILLIPS 66 CO

A method for removing impurities and improving quality of solid waste pyrolysis liquid phase product and product

ActiveCN111440635BReduce generationEfficient disposalGaseous fuelsLiquid carbonaceous fuelsPtru catalystFluid phase

The invention belongs to the field of solid waste treatment, and specifically discloses a method for removing impurities and improving the quality of solid waste pyrolysis liquid phase products and the product. The method specifically includes: mixing a lithium-based molten salt temperature regulator and a calcium-magnesium composite molten salt to obtain a primary molten salt system, introducing the solid waste pyrolysis liquid phase product into the primary molten salt system, heating and maintaining the temperature for a preset time, In this way, impurities can be removed at low temperature and a first-level liquid phase product can be obtained; a second-level molten salt system can be obtained by mixing the transition metal catalyst and sodium-potassium composite molten salt, and the first-level liquid phase product can be introduced into the second-level molten salt system, heated and kept warm Set the time to achieve high-temperature upgrading and obtain the secondary liquid phase product; condense and separate the secondary liquid phase product, and collect the uncondensed gas and clean homogenized liquid phase product respectively. The present invention uses a molten salt cascade treatment method to classify the solid waste pyrolysis liquid phase product, which not only reduces the generation of pollutants, improves production efficiency, but also realizes effective disposal of the solid waste pyrolysis liquid phase product.

Owner:HUAZHONG UNIV OF SCI & TECH

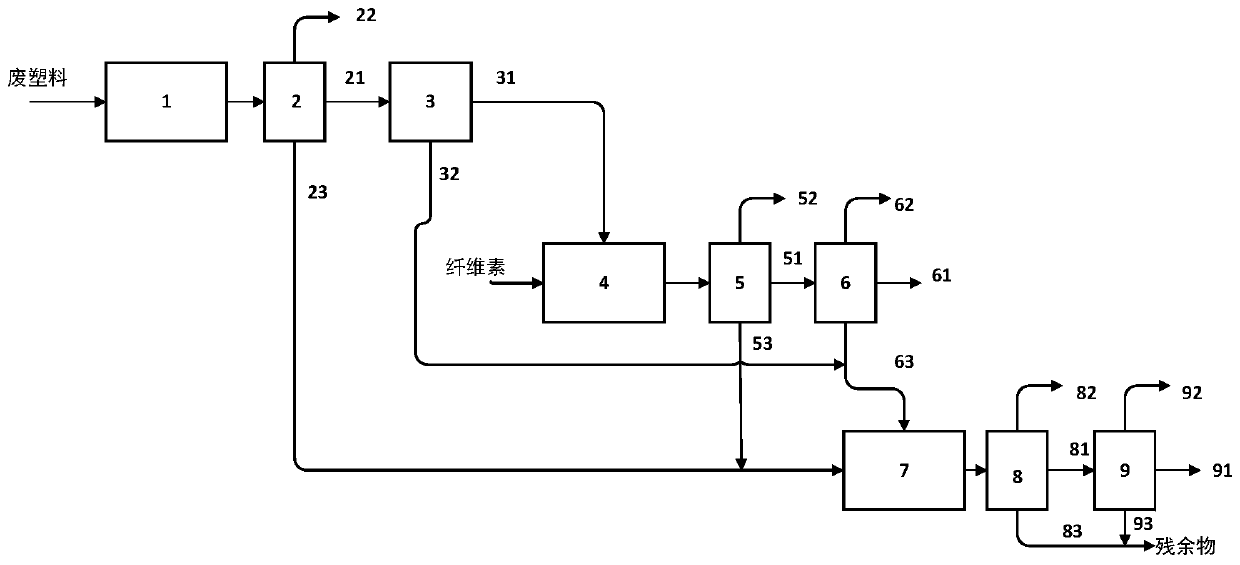

A method of processing waste plastics and cellulose

ActiveCN108117882BImprove conversion rateHigh cracking rateLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesCelluloseLiquid product

The invention discloses a method for processing waste plastics and cellulose. The method comprises the following steps: carrying out catalytic cracking on waste plastics to obtain a product; separating the product to obtain a liquid product I, gas I and an undissolved substance I; mixing the liquid product I through a mixed solvent of tetrahydrofuran and cyclohexane to obtain a mixed solvent of aliquid product II and a residual liquid product III; carrying out a catalytic reaction on the mixed solvent and cellulose; separating the mixture to obtain a liquid product I, gas I and an undissolvedproduct i; carrying out extraction on the liquid product i separately through tetrahydrofuran and cyclohexane to obtain a liquid product ii, a liquid product iii and a residual liquid product iv; carrying out deep catalytic cracking reaction on the liquid products III and iv and the undissolved substances I and I to obtain a product; carrying out gas-liquid-solid separation on the product; and extracting and separating the separated liquid product V separately through tetrahydrofuran and cyclohexane to obtain a liquid product VI and a liquid product VII. According to the method, not only thetotal conversion rate be improved, but also a target reaction is promoted to improve the liquid yield.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

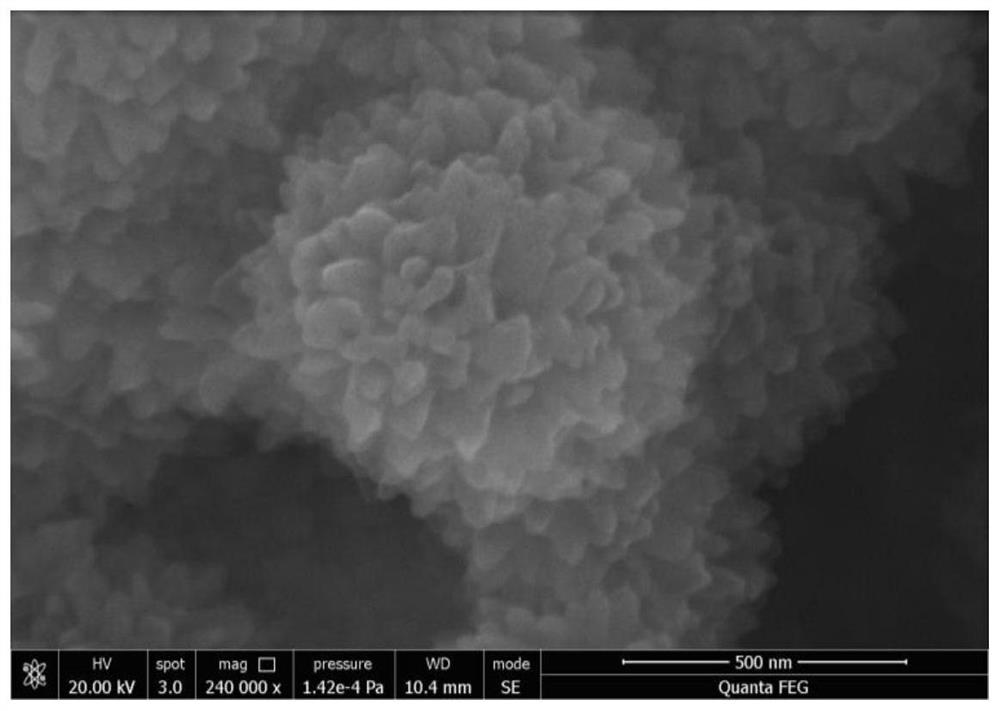

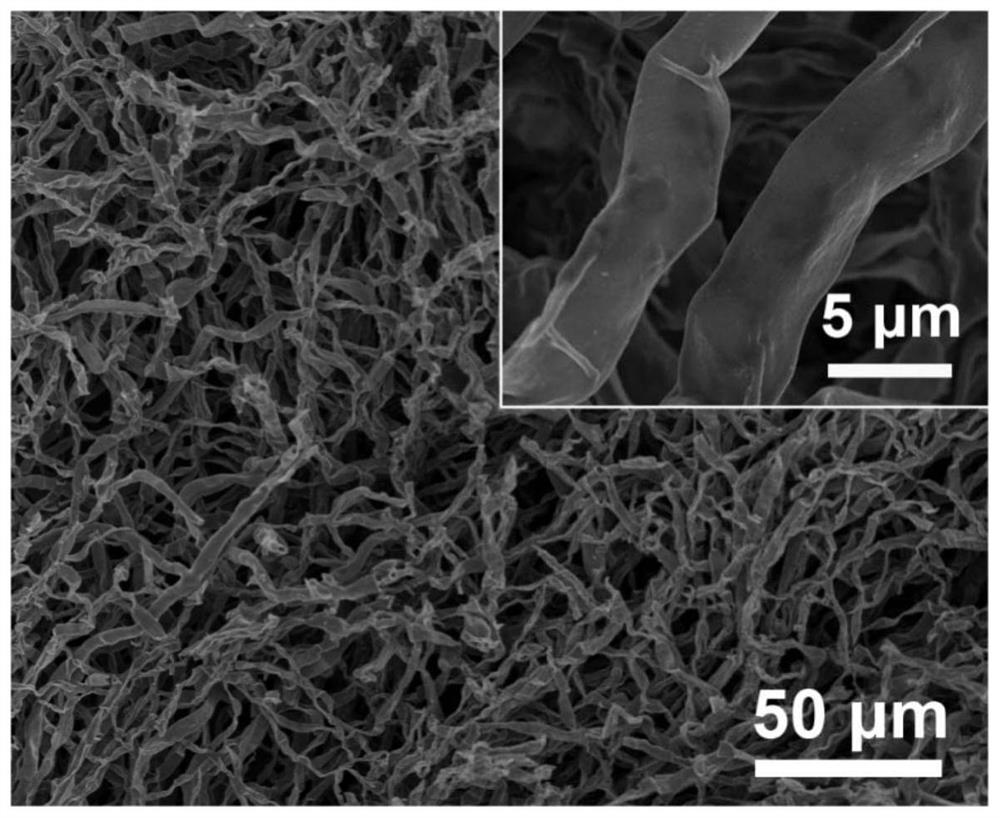

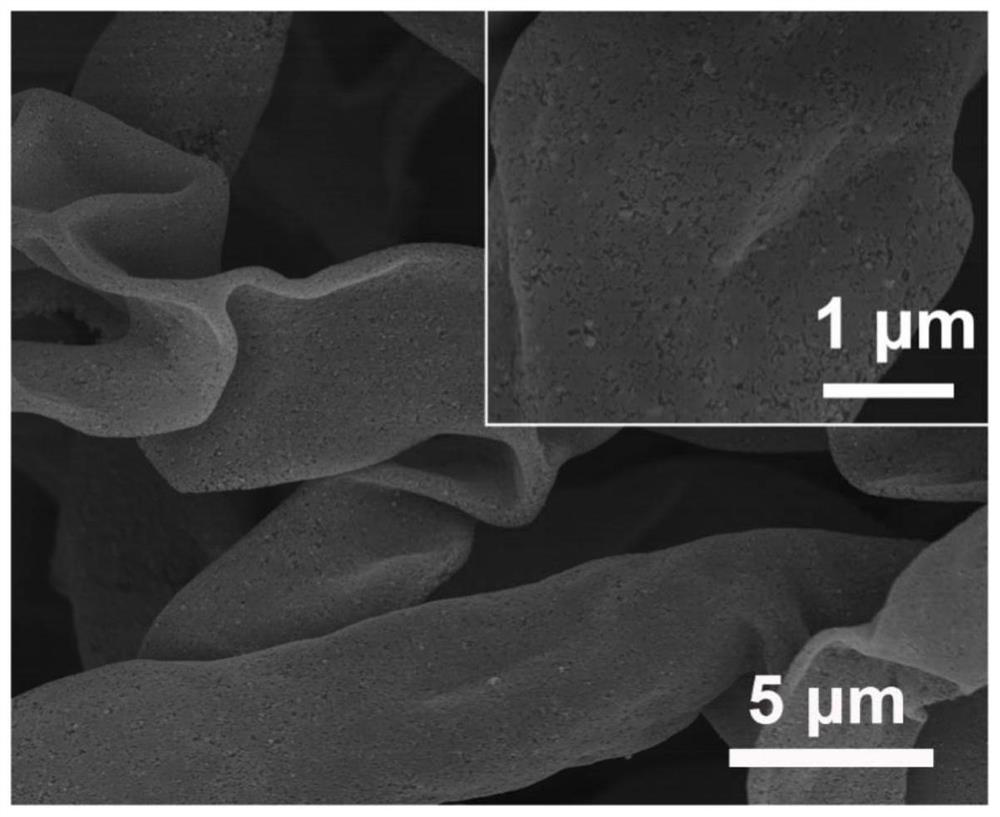

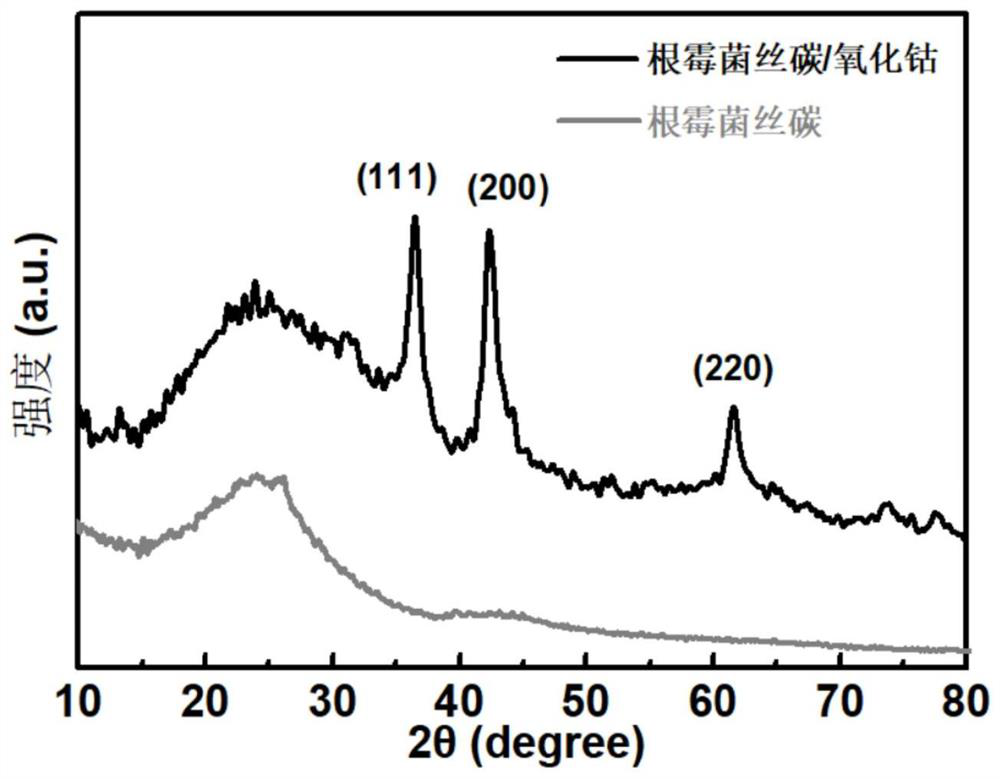

A kind of sulfur-rizopus mycelium spherical carbon/metal oxide composite material and its preparation method and application

The invention discloses a sulfur-rhizopsis mycelium spherical carbon / cobalt oxide composite electrode material and its preparation method and its application as a positive electrode material of a lithium-sulfur battery. The Rhizopus mycelium carbon / cobalt oxide composite was generated. The composite material is used as a host, and reacted for 5-16 hours by a melting sulfurization method to obtain a sulfur-rhizobium hyphae ball carbon / cobalt oxide composite electrode material. The sulfur-rizopus mycelium spherical carbon / cobalt oxide composite electrode material of the present invention is cheap and easy to obtain, can be prepared on a large scale, and has the advantages of high specific capacity, high rate performance and high cycle life, and is widely used in mobile communications, electric vehicles, and smart grids. And aerospace and other fields have broad application prospects.

Owner:ZHEJIANG UNIV

Nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-shaped porous material, lithium battery separator and preparation method, lithium-sulfur battery and electrical equipment

ActiveCN111285348BImprove adsorption capacityStop the spreadSecondary cellsCarbon preparation/purificationCarbon compositesLithium–sulfur battery

The invention provides a nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-shaped porous material, a lithium battery diaphragm and a preparation method, a lithium-sulfur battery and electrical equipment. The preparation method of nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-shaped porous material: mixing raw materials including iron source, nitrogen-containing organic matter, phytate and organic solvent, and drying to obtain a precursor; heating the precursor The nitrogen-phosphorus-doped carbon-composite iron phosphide three-dimensional rod-shaped porous material for the lithium-sulfur battery diaphragm is obtained through processing. The preparation method of the lithium battery diaphragm: mix the raw materials including the nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-shaped porous material, the binder and the solvent, and disperse to obtain the coating slurry; apply the coating slurry on The surface of the diaphragm base material is obtained to obtain the lithium battery diaphragm. The nitrogen-phosphorus-doped carbon-composite iron phosphide three-dimensional rod-shaped porous material, lithium battery separator and preparation method, and lithium-sulfur battery provided by the application can effectively solve the "shuttle effect" and improve the electrochemical performance of the lithium-sulfur battery.

Owner:湖南桑瑞新材料有限公司

Process for preparing sulfuric acid by blending combustion of pyrite concentrate with ferrous sulfate

PendingCN114671412AIncrease contact areaIncrease oxygen contentSulfur compoundsCatalytic transformationCombustion

The invention discloses a process for preparing sulfuric acid by blending and burning pyrite concentrate with ferrous sulfate. The process comprises the following steps: S1, preparing preparation equipment; s2, raw material treatment; s3, roasting is carried out; s4, a purification step; s5, carrying out dry suction; s6, carrying out conversion; and S7, preparing a finished product. According to the process for preparing sulfuric acid by blending combustion of pyrite concentrate with ferrous sulfate, the internal diffusion resistance can be reduced and the contact area between air and ore can be increased due to the small particle size of the pyrite concentrate with the particle size of 3mm, the measure is most effective for controlling the total roasting rate through oxygen diffusion, and the total roasting rate can be controlled by increasing the oxygen content of furnace entering gas; the oxygen concentration in the atmosphere is high, external diffusion and internal diffusion cone power of oxygen is large, the diffusion rate of the oxygen is high, the oxygen content in the furnace gas can be increased, catalytic conversion of So2 is facilitated, the process is simple and convenient, the cost is low, and sulfuric acid with high purity can be prepared.

Owner:SICHUAN DONGLI TECH CO LTD

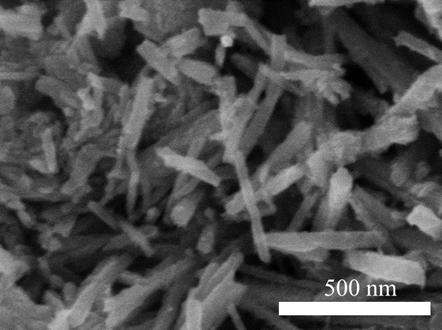

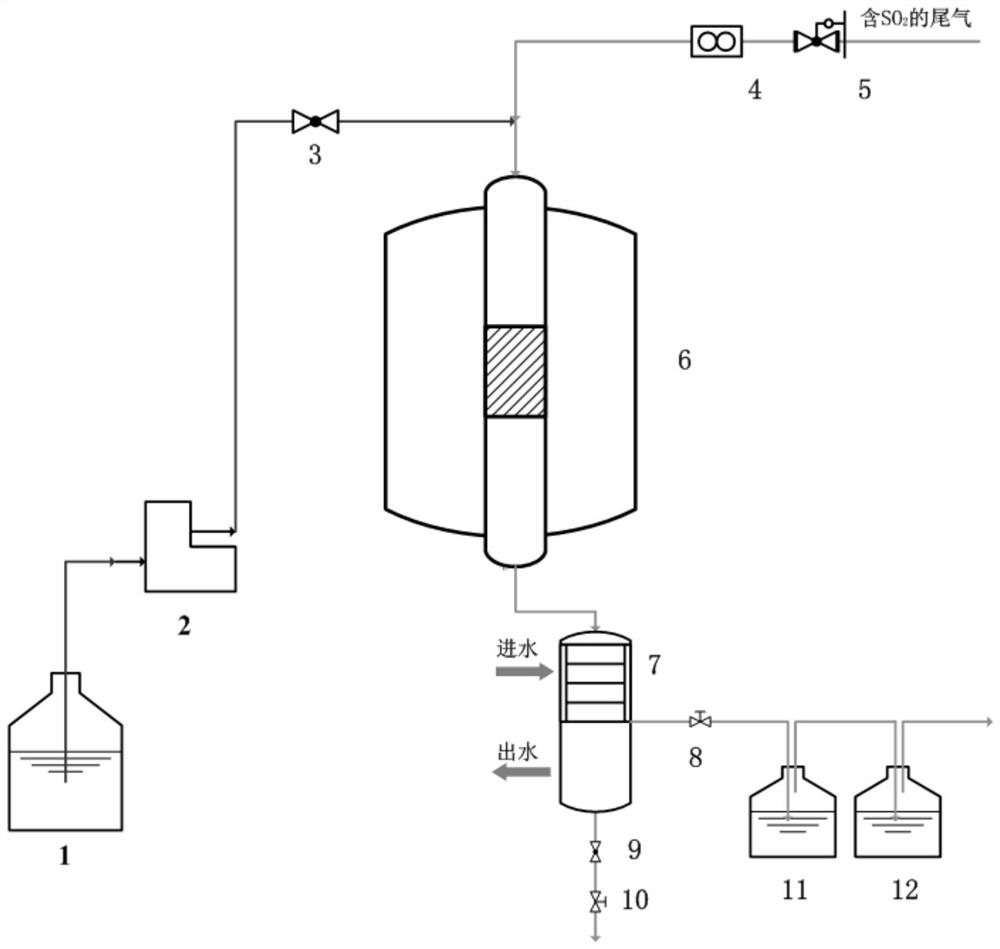

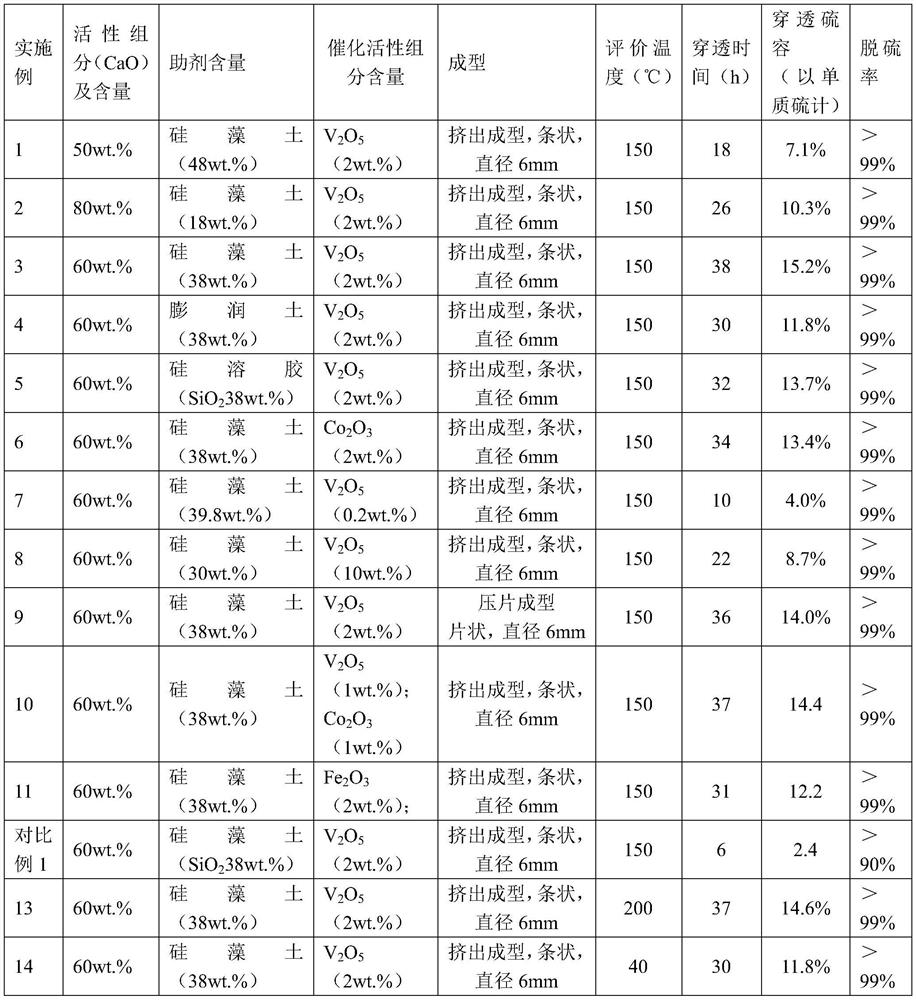

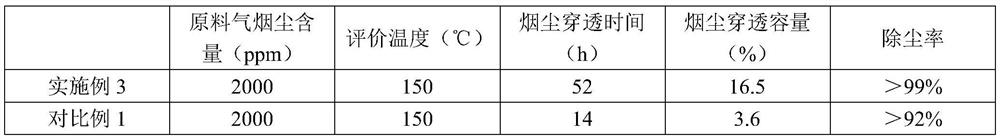

A kind of low-temperature dry flue gas desulfurizer and its preparation method and application

ActiveCN109603459BLow costHigh porosityGas treatmentDispersed particle separationChemical industryFlue gas

The invention discloses a low-temperature dry flue gas desulfurizer and a preparation method and application thereof, which are used for removing SO2 and SO3 components in the low-temperature (40-200DEG C) flue gas, and relates to the field of the flue gas desulfurization purification in coal-fired power plants, heat supply boilers, metallurgy and chemical industries. The desulfurizer comprises an active component CaO, a reaction auxiliary agent silicon source and a catalytic active component V, Fe or Co, wherein cheap quicklime is selected as the raw material of the active component, the silicon source as the auxiliary agent, comprising diatomite, bentonite, silica sol and other silicon sources, and V2O5, Fe2O3, Co2O3 or a combination thereof as the catalytic component. The desulfurizerhas the advantages of low raw material cost, good desulfurization effect, high sulfur capacity, low use temperature to normal temperature, and great breakthrough on low-temperature flue gas dry desulfurization. The desulfurizer matched with a dry moving bed desulfurization process or a fixed bed dry desulfurization process has both desulfurization and dust removal effects in the application process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Systems for selective naphtha reforming

ActiveUS10421918B2Increase contactPromote dehydrogenationNaphtha treatmentChemical/physical processesNaphthaLiquid hydrocarbons

Owner:PHILLIPS 66 CO

A kind of preparation method and application of metal Ni-doped hierarchical porous ZSM-5 molecular sieve

ActiveCN109078652BFacilitate catalytic conversionHigh yieldMolecular sieve catalystsCatalyst activation/preparationCatalytic pyrolysisCatalytic reforming

The invention discloses a preparation method and application of Ni-doped hierarchical porous ZSM-5 molecular sieve. The preparation method includes the steps of pretreating a molecular sieve, namely roasting to remove a templating agent and water; etching the molecular sieve with HF (hydrofluoric) acid solution to generate a hierarchical porous structure; loading high-activity metallic nickel by impregnation; carrying out sheeting and screening. Application of the molecular sieve herein in catalytic quick pyrolysis of biomass is also disclosed. The zeolite HZSM-5 that is low in price and easyto obtain is used herein as a matrix; desilication and dealumination treatment is performed while fiver-membered and ten-membered ring intersection micro porosity of the matrix is utilized, so that hierarchical pores good for entering of macromolecules are generated. The preparation method herein allows acid site distribution to be reduced at the premise of pore expansion; on such basis, the low-price metallic nickel with high hydrogen transfer capacity is added, so that high passing rate and high conversion rate of macromolecules during catalysis are achieved. A catalyst prepared via the preparation method has the advantages of low price, good access convenience, and simple process, is mainly applicable to the catalytic pyrolytic test of biomass or coal, and has a good prospect of catalytic reforming of pyrolytic volatiles.

Owner:CHINA UNIV OF MINING & TECH

Gasoline preparing method by refining plant oil and oxygenated chemicals together

ActiveCN102206503BFacilitate catalytic conversionHigh selectivityLiquid hydrocarbon mixture productionBio-feedstockMolecular sieveVegetable oil

A gasoline preparing method by refining plant oil and oxygenated chemicals together. The method comprises the steps that: preheated plant oil and oxygenated chemicals are injected into a fluidized bed reactor to contact with a catalyst containing a molecular sieve and carry out a catalytic conversion reaction; then generated reaction oil gas and a spent catalyst are separated; the separated spent catalyst is treated with stripping and singe and sent back to the reactor for cycle use; the separated reaction oil gas is fractionated to obtain target products of liquefied gas, gasoline, diesel oil and heavy oil. According to the method provided by the invention, a co-refining of the plant oil and the oxygenated chemicals is conducive to reaction temperature control, and can raise a selectivity of target product gasoline and energy consumption. As for the reaction apparatus, equipment flow is simplified because a heat exchanger for removing reaction heat is omitted.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com