Pyrolysis, carbonization and catalysis integrated method

A technology of pyrolysis carbonization and catalytic chamber, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of low energy utilization, high energy consumption, and high cost, and achieve fuel cost savings , Low preparation cost, easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

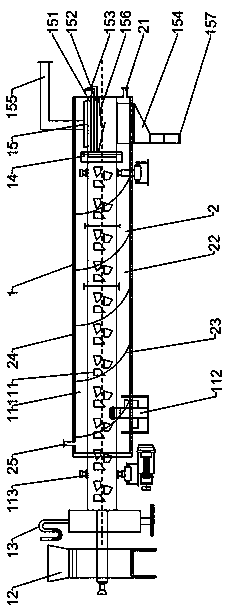

Image

Examples

Embodiment 1

[0030]Using biomass such as corn stalks as raw materials, the stalks are crushed into small particles with a particle size of 1-5 cm, dried at 70°C-120°C until the moisture content is 10%-15%, and granulated by crushing and drying machinery. Processed into particles smaller than 5cm; the processed raw materials are fed and evenly distributed under sealed conditions, and pyrolysis reaction is carried out in an environment of 720°C, and then thermal Decompose oil-gas mixture and biochar. The pyrolysis oil-gas mixture is subjected to a tar catalysis process in the catalytic chamber integrated with the pyrolysis furnace. The biochar catalyst in the catalytic chamber catalyzes the cracking of tar particles in the oil-gas mixture into small molecular gases such as methane and hydrogen at a temperature above 690°C. The catalytic chamber is equipped with a pressure gauge and a pressure alarm device, which has an alarm function for excessive pressure. At the same time, after the carb...

Embodiment 2

[0036] The difference from Example 1 is that the pyrolysis reaction temperature is 700°C, the heat preservation carbonization temperature is 600°C, and the tar catalytic cracking temperature is 800°C.

Embodiment 3

[0038] The difference from Example 1 is that the pyrolysis reaction temperature is 630°C, the heat preservation carbonization temperature is 530°C, and the tar catalytic cracking temperature is 690°C.

[0039] The pyrolysis and carbonization temperature of the system of the present invention is controlled at 630-720°C, and the tar content in the original pyrolysis gas produced by carbonization is 15%-20%. The nickel-based biochar catalyst prepared by the present invention has a nickel loading of 1.5%. Tar is at 750-850°C, the reaction time reaches 20min, and the concentration is 1.06g / m 3 The carbon conversion rate can reach 78.5%, and the cracking rate can reach more than 80% in a short time.

[0040] The present invention can keep the biomass at the optimal pyrolysis temperature of 600°C, and at the same time maintain the catalytic temperature of the biochar above 700°C, play the role of tar removal, and realize the optimum pyrolysis of biomass, tar removal and catalyst reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com